Choosing the right material for packaging is important. If you want your packaging to look special, colored board is a good choice. It makes your packaging stand out and look fancy. If you need strong and cheap packaging, greyboard is better. Think about what is most important for your packaging:

Do you want your brand to look fancy or high-end?

Is it more important for your packaging to look nice or be cheap?

Do you want packaging that is good for the environment and looks fancy?

Does your product need strong protection or just simple safety?

Fancy packaging usually uses colored board to look nice. If you want strong and cheap packaging, use greyboard. Fancy brands use special finishes and materials to get noticed.

Key Takeaways

Pick colored board if you want packaging that looks fancy. It has bright colors and feels smooth.

Use greyboard for packaging that is strong and saves money. It works well for heavy things and keeps them safe.

Think about the environment. Both colored board and greyboard can be recycled. They are made from recycled stuff.

Look at what your product needs. Colored board is good for light things. Greyboard is better for heavy or breakable items.

Check your budget. Colored board costs more because it looks nicer. Greyboard is cheaper and helps save money.

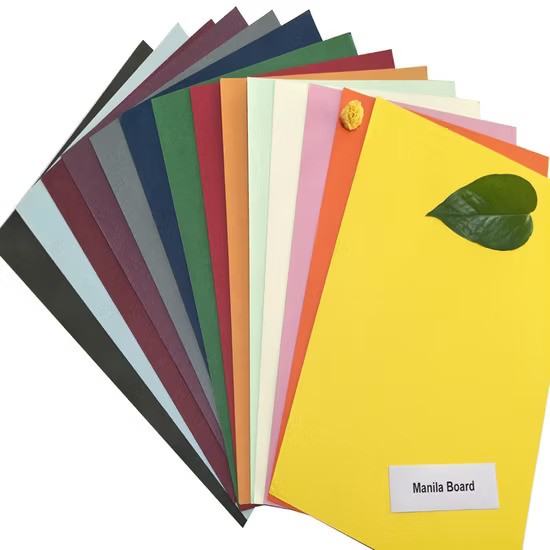

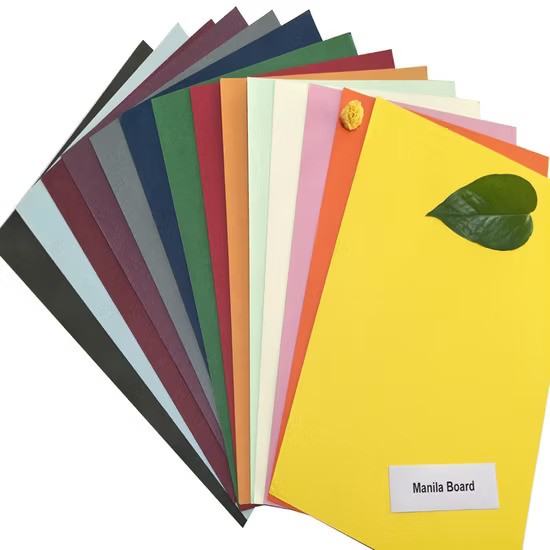

Colored Board Overview

What Is Colored Board

Colored board is used for fancy packaging in stores. It is a kind of duplex board. Makers press layers of paper together to make it. The top layer is white and smooth. This helps printed designs look bright and clear. Duplex board is popular for packaging. It gives products a neat and professional look.

Duplex board comes in different thicknesses. You can pick the one you need. Colored board is also called duplex board because it has two layers. The top layer is for printing. The bottom layer makes it strong. Colored board is used in boxes for cosmetics, electronics, and food. Duplex board helps packaging stand out on shelves.

Features of Colored Board

Colored board has many features for fancy packaging. It is strong and keeps products safe. Duplex board does not bend or break easily. You can use colored board for packaging that looks good and lasts long.

Tip: Pick colored board made from duplex board if you want packaging that looks fancy and protects your product.

Here are the main features of colored board:

| Feature | Description |

| Superior Whiteness | Gives a bright surface for sharp printed colors and designs. |

| High Durability | Stays strong and keeps its shape, even with heavy items. |

| Hygienic Properties | Safe for food and medicine because it uses virgin pulp. |

| Vibrant Printability | Lets you print detailed, colorful images for branding. |

| Premium Appearance | Gloss coating makes your packaging look upscale and attractive. |

| Lightweight & Cost-Effective | Saves money on shipping without losing quality. |

| Sustainable & Recyclable | Made from recycled paper, so it is good for the environment. |

Duplex board has a smooth finish and is strong. Colored board is great for packaging that needs to look special. You can use duplex board for boxes, cartons, and displays. Colored board helps your brand stand out and keeps products safe.

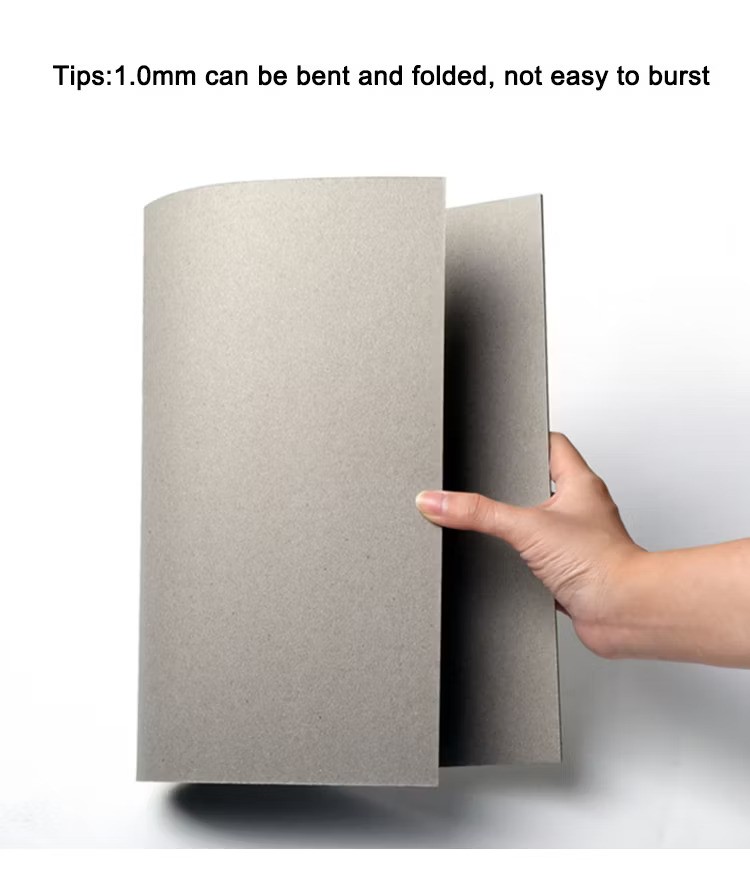

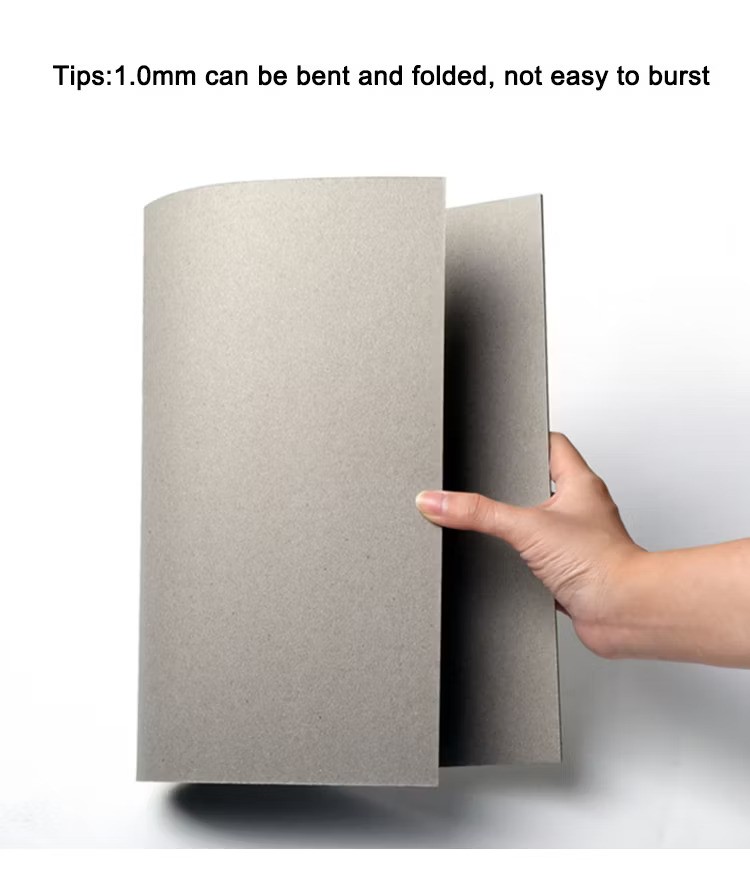

Greyboard Overview

What Is Greyboard

Greyboard is used for packaging books, boxes, and folders. Grey back board is thick paperboard made from recycled paper. Makers use a special process to make it. They start by steaming and heating wood chips in big ovens called digesters.

First, wood chips are steamed and heated in large ovens. These ovens are called digesters. The chips turn into pulp with chemicals. This makes the pulp strong and flexible. The pulp is washed to remove extra chemicals.

Next is the recovery process. Chemicals are evaporated from the pulp. The pulp is washed again. A bleaching agent is added to make it lighter. This also removes leftover organic stuff. Processing chemicals are added to make the pulp better.

Grey back board is named for its gray color on one side. You can use greyboard for packaging that needs to be strong. Grey back board is popular because it is sturdy and cheap. Many industries use greyboard when they need tough packaging.

Features of Greyboard

Grey back board has features that make it a good choice. You can trust greyboard for heavy-duty packaging. Grey back board is strong and does not bend easily. You can cut and shape grey back board for different uses.

Here are the main features of greyboard:

| Feature | Description |

| Strength and Durability | Greyboard is strong and holds a lot of weight. It works for many uses. |

| Cost-Effectiveness | Grey back board costs less than plastic or metal. It gives good quality for a low price. |

| Eco-Friendly | Grey back board is made from recycled paper. It helps the environment by reducing waste. |

| Versatility | You can cut and shape grey back board for many uses. It works in different industries. |

Grey back board costs less than plastic and acrylic.

You get good quality for a low price.

Greyboard is tough and handles lots of use and shipping.

Grey back board saves money and keeps products safe. You can pick greyboard for packaging that lasts through shipping and storage. Grey back board is good for the environment because it uses recycled paper. Greyboard is a smart choice for packaging that needs to be strong, cheap, and eco-friendly.

Key Differences Between Chipboard and Greyboard

Material and Manufacturing

You may ask what makes chipboard and greyboard different. Both use recycled materials, but they are not the same. Chipboard is made from wood scraps and glue. It has many layers that make it firm. Greyboard uses recycled paper pulp. Most greyboard is one solid piece with different thicknesses.

Here is a table to help you compare:

| Material Type | Composition | Structure Characteristics |

| Chipboard | Fast-growing wood scraps | Multi-layer structure |

| Greyboard | Recycled paper pulp | Single material, various thicknesses |

Both chipboard and greyboard come from recycled things. Using them helps cut down on landfill waste. Makers press chipboard and greyboard together with glue or resin. Chipboard is made from waste paper turned into pulp. Greyboard comes in thicknesses from 0.1 to 2.5mm. You can choose the best one for your packaging.

Tip: If you want packaging that is good for the planet, chipboard and greyboard are both smart picks.

Strength and Uses

Chipboard is dense and stiff. It does not bend easily. But chipboard can get damaged by water. Greyboard is strong and lasts a long time. It protects heavy items well. You see greyboard used for boxes for electronics and clothes. Chipboard is good for flat packaging like cereal boxes and shoeboxes.

Here is a quick comparison:

| Feature | Chipboard | Cardboard/Greyboard |

| Density | Denser, more rigid | Lightweight, less sturdy |

| Durability | Resists bending, moisture sensitive | Strong with impact resistance |

| Best Use | Flat, firm packaging | Shipping, cushioning, luxury packaging |

Chipboard is used for packaging inserts and medicine boxes. Greyboard keeps products safe during shipping. It helps brands look fancy. You also find greyboard in shoeboxes, book covers, folders, and puzzles. Knowing the difference helps you pick the right packaging material.

Appearance and Printability

Visual Appeal

How packaging looks is important. Colored board has a bright, smooth top. This makes boxes look neat and nice. Brands use colored board to show sharp colors and clear pictures. The white surface helps designs pop out. Many fancy brands pick colored board for a high-end look.

Greyboard looks different. It is usually grey or brown. This is because it uses recycled paper. The surface feels rough. If you want a natural look, greyboard is a good choice. Some brands use greyboard to show they care about nature. You can add a coating to make greyboard smoother. But it will not shine like colored board.

Tip: Colored board is best if you want packaging that stands out.

Printing Quality

Printing matters a lot for packaging. Colored board gives great print quality. Its smooth surface lets you print bright colors and clear pictures. You get sharp lines and nice images. This is good for packaging with logos or photos.

Greyboard does not print as well. Its rough surface can make colors look dull. You may need a coating for better printing. Greyboard works best for simple designs. It is good when print quality is not the main thing.

Here is a table to compare print quality:

| Feature | Grey Board | Kappa Board (Colored Board) |

| Surface Finish | Slightly rough, may need coating | Smoother, ideal for fine printing |

| Color | Grey or brown | Bright white or off-white |

| Applications | Cost-effective, bookbinding, inserts | High-end packaging, luxury branding |

Pick colored board if you want packaging with great print quality. Greyboard is strong and eco-friendly. It is good when print quality is not as important.

Durability and Strength

Structural Performance

When you choose packaging, you want to know how well it holds up. Colored board and greyboard offer different levels of strength. Colored board feels smooth and looks bright, but it does not match the strength of greyboard. You often see colored board used for lightweight packaging, such as boxes for cosmetics or electronics. Colored board works well when you need packaging that is easy to carry and does not need to hold heavy items.

Greyboard stands out for its strength. You find greyboard in packaging for books, folders, and luxury items. The thickness and durability of greyboard make it a top choice for protecting valuable products. You can pick greyboard in thicknesses from 0.3 mm to 1.5 mm. This range lets you match the strength to your needs. Greyboard keeps its shape during shipping and handling. You can trust it to protect your products.

Note: If you want packaging that stays strong and lasts, greyboard gives you better durability than colored board.

Here is a quick table to help you compare:

| Material | Strength Level | Best Use | Lightweight |

| Colored Board | Moderate | Lightweight packaging | Yes |

| Greyboard | High | Heavy-duty packaging | No |

Suitability for Heavy Items

You need packaging that protects heavy or fragile products. Greyboard is ideal for this job. Its strength and durability help keep items safe. Many luxury brands use greyboard for packaging expensive goods. You can customize greyboard to fit your product. This makes your packaging strong and attractive.

Colored board does not offer the same strength. You should use colored board for lightweight packaging only. It works best for items that do not need much protection. If you pack heavy items, colored board may bend or break.

Greyboard protects heavy products during shipping.

You can choose the right thickness for extra durability.

Colored board is best for lightweight packaging and simple displays.

Greyboard gives you peace of mind when you ship valuable or fragile items. Colored board helps your packaging look good, but it cannot match the strength of greyboard.

Cost Comparison

Colored Board Cost

When you choose colored board for your packaging, you often pay more than you would for other materials. Colored board has a smooth, white surface that makes printing look bright and sharp. This special finish adds to the cost. You also pay for the extra steps in making colored board, like coating and pressing the layers together. If you want your packaging to look fancy or to show off your brand, colored board gives you that premium look, but you need to plan for a higher budget.

Colored board works best for products that need to stand out on store shelves. You see it used for cosmetics, electronics, and gift boxes. If you want to impress customers with your packaging, colored board is a smart choice. Just remember, the price goes up if you pick thicker or more coated options.

Tip: If you want to save money, use colored board only for packaging that needs to look special.

Greyboard Cost

Greyboard gives you a strong and affordable option for packaging. You pay less for greyboard because it uses recycled paper and has a simple finish. Many companies pick greyboard when they need sturdy packaging but do not want to spend a lot. You can use greyboard for shipping boxes, book covers, and folders. It protects heavy items without costing too much.

Here is a quick table to compare costs:

| Material | Average Cost | Best Use Cases |

| Colored Board | Higher | Premium packaging, branding |

| Greyboard | Lower | Shipping, storage, heavy items |

Greyboard helps you keep your packaging budget low. You get good strength and protection for less money. If you need to package many items or ship products often, greyboard is a cost-effective choice.

Environmental Impact

Recyclability

It is important to pick packaging that you can recycle. Colored board and greyboard are both easy to recycle. Colored board has layers of paper. You can put it in most paper recycling bins. The smooth top does not stop recycling. Recycling colored board helps the environment.

Greyboard is also good for recycling. It is made from recycled paper. You can recycle it again after using it. Most recycling centers take greyboard. It does not have plastic or metal parts. You can flatten greyboard boxes to save space.

Tip: Check if your recycling center takes your packaging. Make sure materials are clean and dry before recycling.

Here is a quick look at recyclability:

| Material | Recyclable? | Special Steps Needed? |

| Colored Board | Yes | No |

| Greyboard | Yes | No |

Sustainability

If you care about the planet, pick packaging that is sustainable. Colored board often uses recycled paper and safe inks. This helps lower waste and pollution. Some colored boards use water-based coatings. These coatings break down faster in nature.

Greyboard is very sustainable. It uses almost all recycled paper. Making greyboard uses less energy and water than new paper. Picking greyboard helps save trees and cuts landfill waste.

Note: Using recycled materials for packaging saves resources and keeps waste out of landfills.

Common Packaging Uses

Colored Board Applications

Colored board is used for packaging that looks bright. It helps products stand out in stores. You see colored board in boxes for cosmetics and electronics. Food boxes also use colored board. Brands pick colored board to show sharp colors and clear designs.

Colored board is a kind of chipboard. Chipboard is found in gift boxes and display cartons. It is also used for promotional packaging. Chipboard makes packaging feel smooth and look fancy. You can print logos or photos on colored board. Chipboard is good for light packaging like medicine boxes. Small electronics use chipboard too. You can fold chipboard easily for many uses.

Some common uses for colored board are:

Tip: Pick colored board if you want packaging that stands out and helps your brand.

Greyboard Applications

Greyboard is strong and works for many types of packaging. You see greyboard in shipping boxes and book covers. Folders also use greyboard. Chipboard and greyboard both use recycled paper. Greyboard is thicker and tougher than chipboard. Greyboard protects heavy or breakable items.

Chipboard is also used in folding cartons and luxury boxes. Greyboard is good for food packaging like cake boxes. Beverage carriers use greyboard too. You can use greyboard for partition boards and protective layers. Chipboard and greyboard help save money and keep products safe.

Here is a table with main greyboard uses in shipping:

| Primary Use | Examples of Products |

| Luxury and Rigid Box Packaging | Smartphone packaging, Jewelry boxes, High-end gift boxes |

| Folding Cartons | Shoe boxes, Apparel packaging, Pharmaceutical cartons |

| Indirect Food Packaging | Cake boxes, Takeaway containers, Beverage carriers |

| Protective Packaging | Protective layers for fragile items, Partition boards |

You can cut and shape greyboard for many uses. Chipboard and greyboard are used for books and puzzles. Folders also use these materials. Greyboard gives strong protection and is good for the environment.

Note: Use greyboard for packaging that needs to be extra strong and last a long time.

Which One Should You Choose

Decision Factors

When you pick packaging, you need to think about a few things. Every product needs something different. Your packaging should keep your product safe. It should also look nice and not cost too much. Here are the main things to think about:

Cost: You want to spend less money. Chipboard is usually cheaper than other materials. Greyboard is also a good deal, especially if you need strong packaging.

Structural Integrity: Your packaging must keep your product safe. Chipboard is good for light things. Greyboard is better for heavy or breakable items. It is thicker and stronger.

Visual Appeal: If you want your packaging to stand out, chipboard with a colored or white top is a good pick. You can print bright colors and clear pictures on it. Greyboard looks natural and recycled. Some brands use this to show they care about the earth.

Environmental Impact: You might want packaging that is good for the planet. Both chipboard and greyboard use recycled paper. You can recycle them after you use them.

You should also think about what you are packing. For food and drinks, chipboard with a white top keeps things safe and looks nice. For cosmetics, chipboard gives a smooth finish and makes your brand look fancy. Greyboard is strong and protects electronics and luxury items.

Tip: Always pick packaging that fits your product. Think about how it looks, how much it costs, and how well it protects your product.

Quick Reference Table

You might still wonder, "which one should you pick" for your packaging? The table below helps you compare chipboard and greyboard for different uses. This quick guide shows you the best material for each job.

| Application Area | Material Type | Key Features | Best For |

| Food and Beverage | Chipboard (White Laminated) | Moisture resistant, attractive branding, protects food during handling and transport. | Snack boxes, beverage cartons |

| Cosmetics and Personal Care | Chipboard (White Laminated) | Aesthetic appeal, smooth surface, suitable for high-end products. | Cosmetic boxes, gift sets |

| Electronics | Greyboard | Strong, rigid, printable surface for instructions, protects sensitive components. | Device packaging, gadget boxes |

| Luxury Goods | Chipboard (Duplex Board) | Premium feel, exceptional strength, professional presentation. | Jewelry boxes, premium gifts |

| Shipping and Storage | Greyboard | High durability, cost-effective, eco-friendly, protects heavy or fragile items. | Shipping boxes, book covers |

| Promotional Displays | Chipboard | Easy to print, lightweight, customizable shapes. | Display stands, retail signage |

Food and Beverage: Chipboard keeps snacks and drinks safe. It also looks nice in stores.

Cosmetics: Chipboard gives a smooth, bright finish for fancy products.

Electronics: Greyboard protects delicate parts and lets you print instructions.

Luxury Goods: Chipboard with a duplex board finish looks fancy and protects well.

Shipping: Greyboard is best for heavy things and long trips.

Displays: Chipboard is easy to shape and print for cool displays.

You can see chipboard is best when you want great printing and a smooth look. Greyboard is the best pick for strength and protection. Both help you save money and are good for the planet.

Note: If you want your packaging to look fancy and show off your brand, pick chipboard. If you need strong packaging for shipping or heavy things, choose greyboard.

You can find the main differences between colored board and greyboard in this table. Colored board is best for fancy packaging. Greyboard is strong and good for the environment. You can use greyboard for many things.

| Feature | Greyboard | Colored Board |

| Surface Quality | Grey, uncoated back | White, coated sides |

| Cost | Lower | Higher |

| Printability | Good (front) | Excellent (both sides) |

| Strength | Moderate to high | High |

| Ideal Use | Budget, sturdy packaging | Premium, luxury items |

Choose greyboard if you want packaging that is strong and green. Pick colored board if you want packaging that looks fancy.

FAQ

What is the main difference between colored board and greyboard?

Colored board has a white, smooth surface for bright printing. Greyboard looks gray and feels rough. You use colored board for fancy packaging. You pick greyboard for strong, low-cost packaging.

Can you recycle both colored board and greyboard?

Yes, you can recycle both materials. Most recycling centers accept them. Make sure your packaging is clean and dry before recycling. This helps the recycling process work better.

Which material is better for heavy products?

You should use greyboard for heavy products. It gives more strength and protection. Colored board works best for light items that do not need much support.

Is colored board safe for food packaging?

Colored board is safe for food packaging if it uses food-grade materials. Always check with your supplier. Look for packaging that meets food safety standards.

How do I choose the right board for my brand?

Think about your product’s needs. If you want a premium look, choose colored board. If you need strong, budget-friendly packaging, pick greyboard. Consider your brand image and product safety.