Have you ever wondered why paper is so commonly used in food packaging? It’s not just because it's eco-friendly, but also due to its versatility and ability to preserve food. Different types of paper used in food packaging each serve a unique role in protecting food during transport, storage, and consumption.

In this post, we’ll explore the various types of paper used for packaging foods, including Kraft, tissue, and parchment. You’ll learn about their benefits, common applications, and what makes each paper type ideal for certain food products.

Types of Paper Used in Food Packaging

Food packaging plays an essential role in preserving the quality of food, ensuring its safety, and providing ease of transportation. Different types of paper materials are used in food packaging for various reasons, including moisture resistance, durability, eco-friendliness, and presentation. Below are the most commonly used types of paper in food packaging, their benefits, applications, and manufacturing processes.

Kraft Paper for Food Packaging

Definition and Composition of Kraft Paper

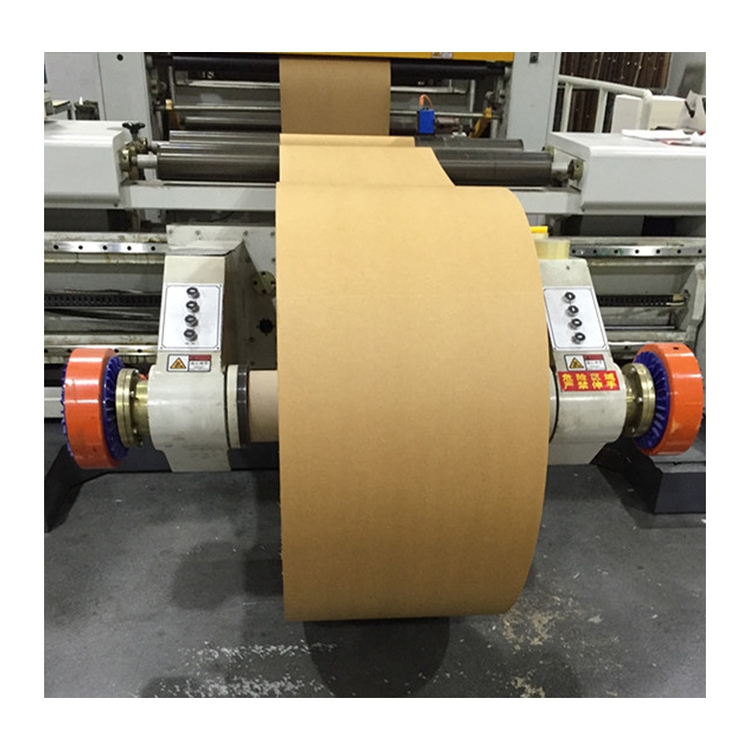

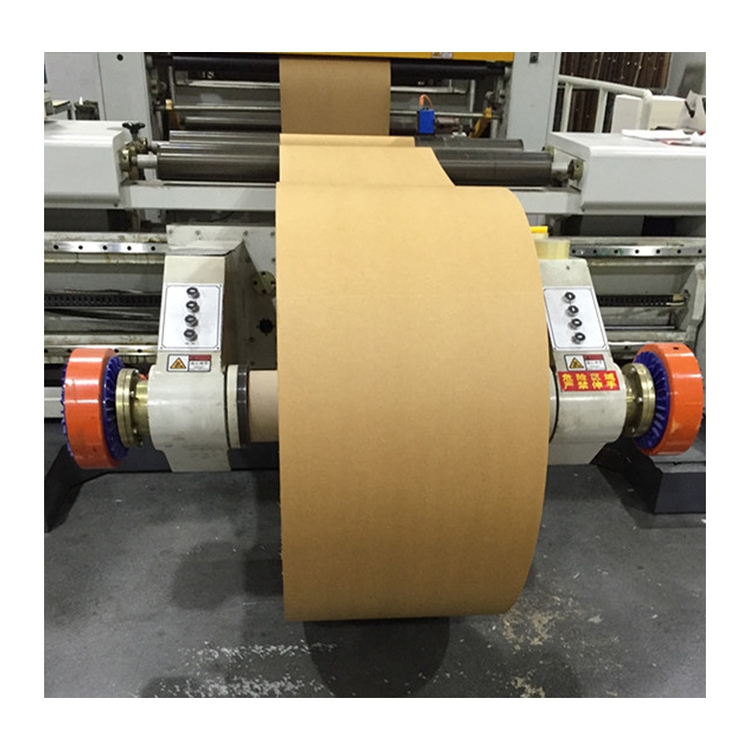

Kraft paper is made from wood pulp that undergoes a chemical treatment process called the Kraft process, which removes lignin and strengthens the fibers. The result is a durable, unbleached paper, typically brown in color, known for its high tensile strength and ability to resist tearing.

Why Choose Kraft Paper for Food Packaging?

Kraft paper is highly resistant to moisture, making it an ideal material for food packaging. Its strength ensures it can withstand rough handling, and its eco-friendly properties, as it is fully recyclable, make it a sustainable choice for businesses looking to reduce their environmental impact.

Common Uses of Kraft Paper

Cereal Boxes: Kraft paper is commonly used for packaging dry foods like cereals.

Takeaway Bags: It's often used for packaging takeaway food, providing durability and moisture resistance.

Pizza Box Liners: Kraft paper serves as the inner lining of pizza boxes, preventing moisture from leaking through and keeping the pizza fresh.

Kraft Paper Manufacturing Process

Kraft paper is produced by chemically treating wood pulp with sodium hydroxide and sodium sulfide to remove lignin, which is the material that makes paper weak. The result is a stronger, more durable paper that is resistant to moisture and tearing.

Tissue Paper in Food Packaging

What is Tissue Paper?

Tissue paper is a thin, delicate material made from cellulose, often used for wrapping or cushioning food items. It comes in a variety of colors and designs, making it a versatile choice for food packaging and presentation.

Why is Tissue Paper Used in Food Packaging?

Tissue paper helps protect food from moisture, oxygen, and grease. It also adds an aesthetic element to packaging, making food products appear more appealing while serving functional purposes like cushioning and wrapping.

Common Uses of Tissue Paper

| Use | Examples |

| Bakery Items | Wrapping cakes, cookies, and pastries |

| Sushi | Wrapping sushi rolls for presentation |

| Box Liners | Lining gift boxes and food containers |

Advantages of Tissue Paper

Tissue paper is lightweight, breathable, and customizable. It’s especially effective at keeping food fresh and preventing contamination from moisture or grease. Its thin texture makes it ideal for wrapping delicate items without adding bulk.

Greaseproof Paper for Food Packaging

What is Greaseproof Paper?

Greaseproof paper is specially treated to resist grease, oil, and moisture. It’s an essential packaging material for greasy and oily foods, preventing oil from soaking through and keeping food dry.

Benefits of Greaseproof Paper in Food Packaging

Greaseproof paper helps maintain the freshness and texture of greasy foods by providing a barrier against oil and moisture. It is particularly useful for packaging fried items and baked goods.

Common Applications of Greaseproof Paper

| Use | Examples |

| Burgers | Wrapping burgers to prevent grease leakage |

| Pastries | Wrapping baked goods like donuts and croissants |

| Sandwiches | Wrapping sandwiches to avoid sogginess |

Greaseproof Paper Manufacturing Process

Greaseproof paper is created by treating the pulp to create a dense paper that resists moisture and grease. This treatment results in a paper that is smooth, non-absorbent, and maintains its structural integrity when in contact with greasy foods.

Glassine Paper for Food Packaging

What is Glassine Paper?

Glassine paper is a smooth, translucent paper made from cellulose. It is resistant to moisture, grease, and oil, making it a popular choice for food packaging.

Why Glassine Paper is Ideal for Food Packaging

Its smooth texture and resistance to moisture and grease make it an excellent choice for packaging foods that need to stay fresh. Glassine’s translucency also allows customers to see the contents of the packaging, enhancing product visibility.

Common Uses of Glassine Paper

| Use | Examples |

| Baked Goods | Packaging bread, cakes, and pastries |

| Candies | Wrapping candies and sweets |

| Meats | Wrapping meats to preserve freshness |

Advantages of Glassine Paper

Glassine paper is lightweight, resistant to moisture and grease, and often used for food items that require long shelf lives. Its ability to be heat-sealed also makes it ideal for packaging hot food.

Waxed Paper for Food Packaging

What is Waxed Paper?

Waxed paper is coated with a thin layer of wax, making it resistant to moisture, grease, and oil. This coating helps preserve food and prevent sticking.

How Waxed Paper Protects Food

Waxed paper creates a protective barrier, preserving the food inside by preventing moisture and grease from entering the packaging. This keeps the food fresh for longer periods.

Common Uses of Waxed Paper

| Use | Examples |

| Sandwiches | Wrapping sandwiches to avoid sogginess |

| Baking | Lining baking trays to prevent sticking |

| Pastries | Wrapping greasy items like pastries |

Benefits of Using Waxed Paper

Waxed paper is non-stick, making it perfect for use in baking or wrapping greasy foods. It helps maintain freshness and is easy to handle and store.

Parchment Paper in Food Packaging

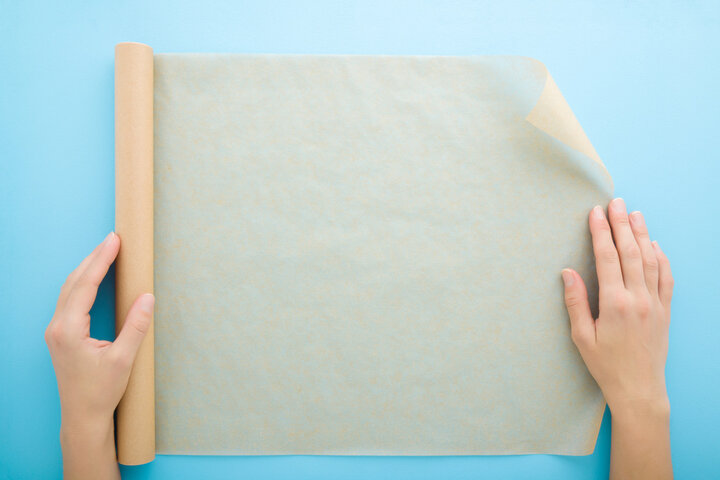

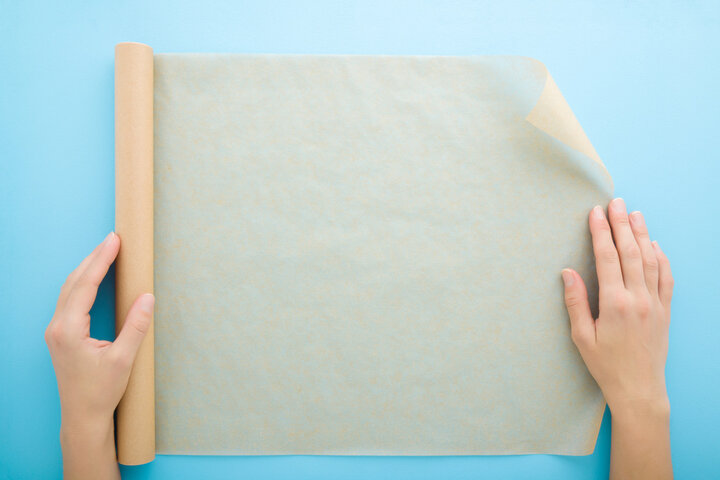

What is Vegetable Parchment Paper?

Vegetable parchment paper is made from plant fibers and treated to provide moisture resistance and durability. This paper type is often used in cooking and food packaging.

Why Choose Parchment Paper for Food Packaging?

Parchment paper offers heat resistance and non-stick properties, making it ideal for packaging food that requires high temperatures, such as baked goods or meats.

Common Uses of Parchment Paper

| Use | Examples |

| Baking | Lining baking trays for cakes, cookies |

| Meat Wrapping | Wrapping meats to retain moisture and flavor |

| Greasy Foods | Packaging greasy or sticky foods like fried items |

Benefits of Parchment Paper

Parchment paper is heat-resistant, moisture-resistant, and non-stick, making it perfect for cooking and preserving food. It ensures easy food release and maintains food quality.

Paperboard in Food Packaging

What is Paperboard?

Paperboard is a thick, rigid material that’s used for packaging. It provides more strength and durability compared to regular paper, making it ideal for heavier food items.

Why is Paperboard Used for Food Packaging?

Paperboard’s rigidity and strength provide excellent protection for food during transport, ensuring that products remain safe from damage.

Common Uses of Paperboard

| Use | Examples |

| Beverage Cartons | Used for milk, juice, and other drinks |

| Take-Out Containers | Common for fast food and take-out packaging |

| Snack Boxes | Used for snack packaging like crackers and chips |

Benefits of Paperboard

Paperboard is sturdy and customizable, allowing for safe transport and efficient storage. It can be easily printed with brand logos and other information.

How to Choose the Right Paper for Food Packaging

Choosing the right paper for food packaging is essential for ensuring food safety, preserving freshness, and meeting brand requirements. Several factors come into play when selecting packaging materials, and understanding these can help you make the best decision.

Factors to Consider When Choosing Food Packaging Paper

Food Type

Different foods need different types of paper packaging. Here are some considerations:

Dry foods like cereals or crackers need papers like Kraft that protect against moisture.

Greasy foods such as burgers or fried snacks require greaseproof or waxed paper to prevent oils from soaking through.

Fresh foods, including meats and fruits, require moisture-resistant papers like Glassine or parchment to preserve freshness.

Shelf Life

Choosing the right paper can help extend food’s shelf life:

Moisture resistance is key for foods that spoil quickly, like fresh produce and meats.

Papers such as Glassine or parchment are great for preserving freshness by preventing exposure to moisture and contaminants.

Waxed and greaseproof papers also prevent the degradation of greasy or oily foods, helping them last longer.

Environmental Impact

As sustainability becomes more important, consider the following:

Recyclable papers, like Kraft, are widely available and eco-friendly.

Compostable options, such as certain waxed and vegetable parchment papers, are also environmentally friendly.

Choosing recyclable or biodegradable materials supports your business’s eco-conscious image and can appeal to consumers looking for sustainable products.

Cost-effectiveness

Balancing quality with budget is important, especially for large-scale production:

Kraft paper is often the most cost-effective option for dry food packaging.

For specialized packaging, such as that needed for high-fat or high-moisture foods, papers like parchment or Glassine may be more expensive but necessary to maintain food quality.

Consider the cost per unit and the long-term benefits of choosing a higher-quality paper for specific food types.

Printer Compatibility

If your packaging requires branding or nutritional labeling, ensure the paper is printer-friendly:

Kraft paper is typically smooth and works well with most printing techniques.

Glassine and parchment papers may require specific inks to ensure clear labeling.

Ensure the paper type is compatible with your printing equipment, especially if you're using a high-volume production setup.

Common Packaging Requirements for Different Food Items

Dry Foods

For dry foods, such as cereals or crackers, Kraft paper is the best option because:

It’s moisture-resistant and durable.

Keeps the food fresh and crisp during transportation.

Its strength prevents damage to the packaging during handling.

Kraft paper is used for products like pasta, crackers, and snack bags.

Greasy Foods

For greasy foods like burgers, pastries, or fried snacks, you need papers that can handle oils and moisture:

Greaseproof paper forms a barrier against oil, preventing leakage and mess.

Waxed paper offers a similar benefit, keeping greasy foods fresh and preventing them from sticking together.

Greaseproof and waxed papers are ideal for products such as burgers, sandwiches, and fried foods.

Fresh Foods

Fresh foods like meats, cheeses, and fruits require packaging that preserves their quality and freshness:

Parchment paper is resistant to heat and moisture, making it ideal for wrapping meats or fish.

Glassine paper offers an airtight seal and moisture resistance, making it perfect for fruits and cheeses.

Parchment and Glassine papers work well for wrapping meats, cheeses, and fresh produce.

Environmental Impact of Paper Packaging

The environmental impact of packaging materials has become a key concern for both businesses and consumers. Paper-based packaging, a more sustainable option compared to plastics, offers several benefits but also presents challenges in recycling. Let’s explore the eco-friendliness of paper packaging, how it compares to plastic, and some of the hurdles faced during recycling.

Are Paper-Based Packaging Materials Eco-Friendly?

Benefits of Paper Recycling and Biodegradability

Paper is one of the most recyclable and biodegradable packaging materials available. It can be recycled multiple times to create new products, reducing the need for virgin pulp. Additionally, paper naturally decomposes in the environment, unlike plastic, which can take hundreds of years to break down.

Recyclable: Paper can be processed into new paper products, reducing waste.

Biodegradable: Unlike plastic, paper breaks down naturally without harming wildlife.

Renewable resource: Paper comes from trees, which can be replanted and regrown.

Comparison to Plastic Packaging

How Paper Stacks Up Against Plastic in Terms of Sustainability

When compared to plastic, paper packaging is generally more sustainable, but it’s not without its environmental impact. Paper is biodegradable, recyclable, and derived from a renewable resource. On the other hand, plastic is made from petroleum-based products, which are non-renewable and take centuries to decompose.

Decomposition: Paper decomposes faster than plastic.

Recyclability: Paper is easier to recycle than plastic, which is often contaminated with food residue.

Energy Use: The production of paper can consume more energy, but it has a smaller environmental footprint when recycled properly.

Recycling Challenges in Paper Packaging

Why Some Types of Paper Are Harder to Recycle Than Others

Not all paper packaging is equally recyclable. Some types of paper, especially those coated with plastic or wax, can be difficult to recycle. For example, waxed paper or paper with heavy coatings needs special handling, which makes the recycling process more complex and costly.

Coated Papers: Papers with coatings (like wax or plastic) are not easily recyclable.

Contamination: Paper with food residues can complicate recycling.

Processing Costs: The cost of recycling certain types of paper is higher, limiting their overall sustainability.

Conclusion

The food packaging industry utilizes a variety of paper types, including Kraft, tissue, greaseproof, glassine, waxed, parchment, and paperboard, each offering unique benefits for different food needs. Choosing the right paper ensures food stays fresh, safe, and easy to transport. Understanding paper properties is key to selecting the best option for both food preservation and packaging efficiency.

By making informed choices based on factors like moisture resistance, heat tolerance, and eco-friendliness, businesses can enhance food quality while also supporting sustainability. When selecting packaging materials, it’s essential to consider both functionality and environmental impact for the best results.

Frequently Asked Questions (FAQs)

What is the most eco-friendly type of paper used in food packaging?

Kraft paper is considered one of the most eco-friendly options due to its recyclability and biodegradable nature. It is made from wood pulp using a chemical process that makes it durable while remaining environmentally responsible.

Is waxed paper safe for food packaging?

Yes, waxed paper is safe for food packaging, as it provides a moisture-resistant layer, helping to preserve freshness. It’s commonly used to wrap greasy foods like sandwiches and pastries.

Can paper packaging be used for both hot and cold food?

Yes, paper packaging can be used for both hot and cold food, depending on the paper type. Materials like parchment paper and waxed paper work well with high temperatures, while greaseproof and Kraft paper are ideal for cold foods.

Why is Kraft paper so commonly used in food packaging?

Kraft paper is favored for food packaging due to its durability, resistance to moisture, and recyclability. It’s ideal for packaging dry foods, takeaway bags, and pizza boxes, ensuring freshness and strength during transport.

Reference Sources

[1] https://theconiferous.com/blog/types-of-paper-used-in-food-packaging/

[2] https://www.yoonpak.com/types-of-paper-used-in-food-packaging/

[3] https://gmz.ltd/5-types-of-paper-in-food-packaging-key-differences/

[4] https://www.webstaurantstore.com/guide/587/types-of-food-wrapping-paper.html

[5] https://noissue.co/blog/the-12-most-common-types-of-packaging-for-food-and-how-to-choose-the-right-one/

[6] https://www.atyourservous.com/types-of-paper-foodservice-products/

[7] https://gdpemballages.com/en/food-paper-types/