You need strong paper for tough jobs because it does not tear easily and stays strong under pressure. Durability and weight are important when you pack, print, or keep valuable things safe. Kraft paper is known for being tough and good for the environment.

More companies want sturdy paper as they move to greener packaging.

The world market for paper and paperboard packaging was $381.4 billion in 2024 and may reach $620.6 billion by 2034, with food, drink, and online shopping leading the way.

Paper weight changes how well your packaging or printed things work. Picking the right thickness or strength helps your project do well.

Key Takeaways

Pick strong paper for tough jobs so it lasts longer and does not rip. Kraft paper is a great pick because it is strong and good for the environment.

Learn about paper weight, which is measured in GSM, to pick the right thickness for your work. If the GSM is higher, the paper is stronger and lasts longer.

Think about how tough the paper is and how it is tested to make sure it can handle rough use every day. Find paper with high tensile and tear resistance.

Use the right paper for what you need. Chipboard works well for dividers, cotton paper is good for important papers, and kraft paper is best for packing heavy things.

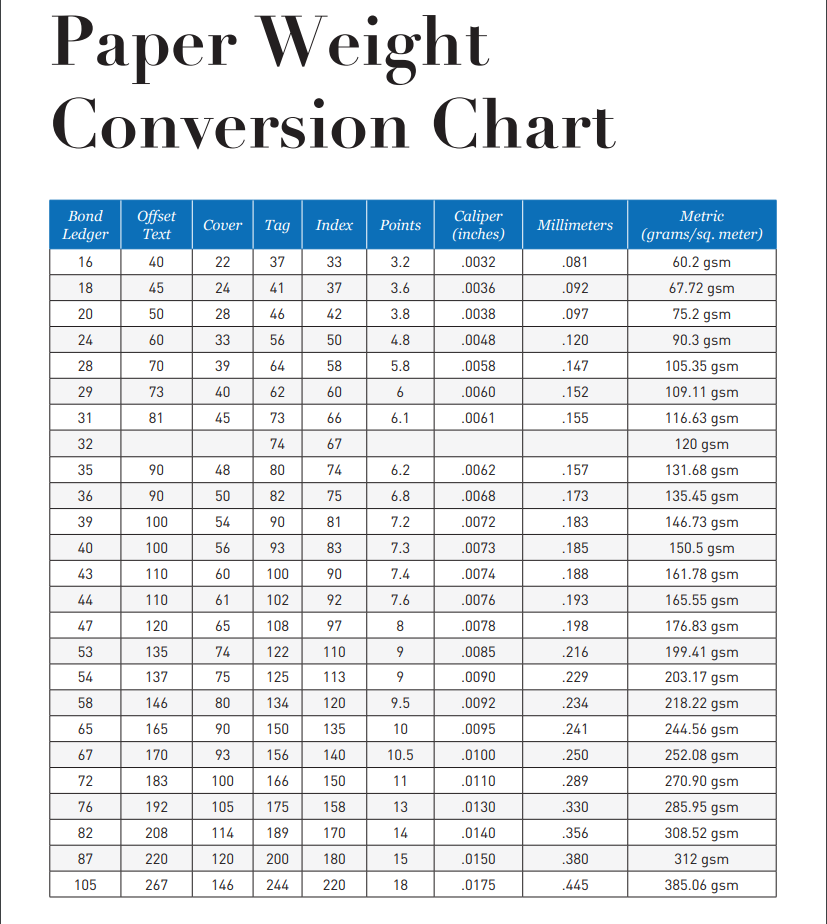

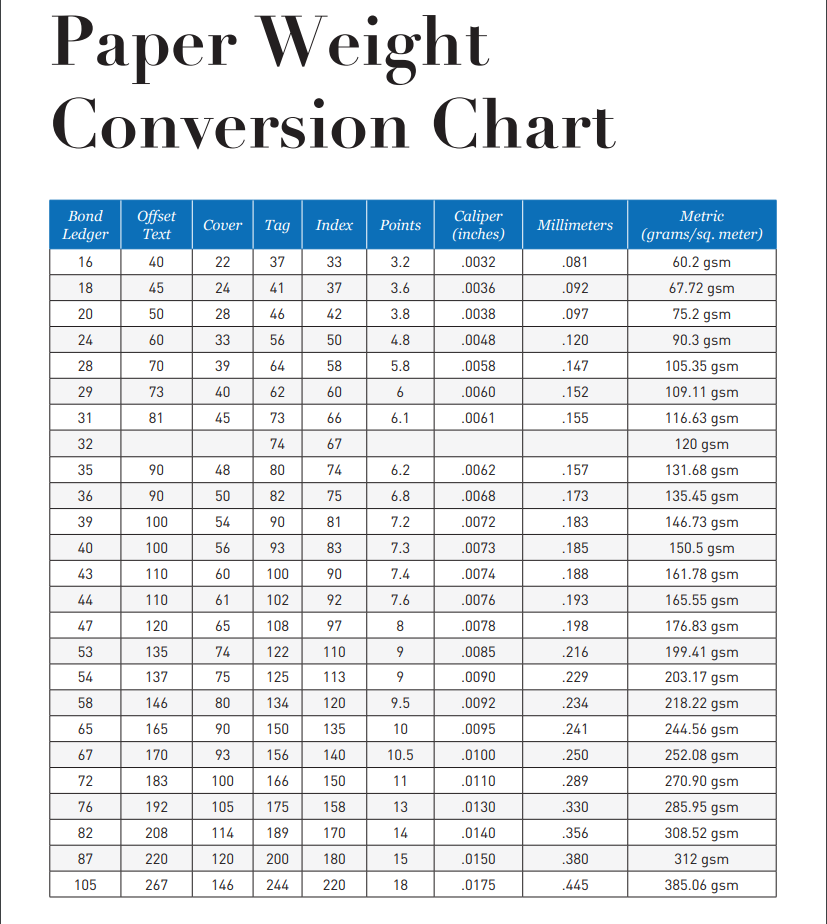

Always look at the paper weight guide before you buy. This helps you not make mistakes and makes sure you get the best paper for your job.

Strong Paper for Heavy-Duty Use

Defining Strength

When you pick paper for hard jobs, you should know what makes it strong. Strong paper does not break or rip easily. It can hold heavy things without falling apart. Two main things help you check this: tensile strength and tear resistance. Tensile strength means how much pulling the paper can take before it snaps. Tear resistance means how well the paper stops a rip from getting bigger. These things are important if you want your packaging or printed stuff to last a long time.

Here is a quick look at the main properties:

| Property | Definition | Application Context |

| Tensile Strength | Resistance to being pulled apart or stretched under tension. | Ropes, cables, structural components. |

| Tear Strength | Resistance to the propagation of a tear once it has started. | Packaging, apparel, upholstery. |

You should also think about fracture toughness. This tells you how much energy the paper can take before a small flaw gets worse. If you use paper with high fracture toughness, your packaging will not break easily. Even if it gets a small cut, it will still work well.

Key Factors

There are many types of strong paper you can pick. Each kind has special features and best uses. Here is a table to help you compare some common types:

| Type of Paper | Characteristics |

| Car Liner Paper | Heavy paper made from kraft pulp or waste paper stock, used for lining freight cars. |

| Check or Cheque Paper | Durable paper for bank checks, reacts to ink eradicators, shows stains with certain chemicals. |

| Chipboard | Thicker than cardboard, used for backing sheets and box partitions. |

| Cotton Paper or Rag Paper | Contains at least 25% cotton fiber, known for its durability. |

| Cover Paper or Cover Stock | Fairly heavy, used for book and brochure covers, folds well. |

| Vulcanizing Paper | Chemically treated for hardness and density, used in insulation and building materials. |

Kraft paper is a great choice for tough jobs. You see it in food packaging, shipping, and factories. Kraft paper is stronger than many other papers, like butcher paper. It does not tear easily and can hold heavy things. This makes it good for wrapping, bagging, and making boxes. You can also recycle kraft paper, which is good for the planet.

Tip: If you want to help the environment, pick strong paper that you can recycle and that breaks down naturally. Many companies now use heavy papers made from recycled stuff to make less trash.

New ways to make strong paper give you more choices. Makers now use green materials and layers to make paper stronger and better for the earth. Special paper cores and biodegradable cores help you pack and ship things safely while being eco-friendly.

When you pick strong paper, match the type to your job. Use chipboard for box dividers, cotton paper for important papers, and kraft paper for heavy things. This helps you get the right mix of strength, toughness, and being green.

Durability Ratings

Measurement Methods

There are different ways to test how tough paper is. These tests show if paper can handle folding, tearing, and daily use. Here is a table with some common tests:

| Method | Description | Sample Requirements | Turnaround Time |

| Köhler-Molin | Folds paper until it breaks to check endurance. | Five A4 sheets, max 0.25 mm | 3 weeks |

| Lhomargy | Repeats folding to measure how long paper lasts. | Five A4 sheets, max 0.25 mm | 3 weeks |

| MIT | Tests folding under a steady load. | Five A4 sheets, max 0.25 mm | 3 weeks |

| Schopper | Uses a special device to measure folding endurance. | Five A4 sheets, max 0.25 mm | 3 weeks |

Tear tests help you know how much force rips paper.

Standards

Look for paper tested with official rules. The Schopper double fold tester uses BS ISO 5626. This rule helps you get good results. Here is a table:

| Method | Description | Standards |

| Schopper double fold tester | Measures how many times paper can fold before breaking. | BS ISO 5626 |

This test is used for money paper, maps, and wrapping paper. These rules help you compare kraft paper and other strong papers.

Real-World Impact

Durability ratings are important for packaging and work jobs. You want your packaging to last through shipping and handling. Some tests match real-life needs:

| Phase | Description | Relevance to Real-World Performance |

| Phase 1 | Micro-Indentation Measurements | Shows how packaging resists cuts from tools. |

| Phase 2 | Scratch Tests | Checks how paper holds up during handling and storage. |

| Phase 3 | Reuse Wear and Washing-Mimicking Experiment | Tests how packaging survives repeated use and cleaning. |

If you pick paper with high durability, your products stay safe and look nice longer. You can trust strong paper for heavy-duty packaging, especially kraft paper for hard jobs.

Paper Weight

GSM and Thickness

Paper weight is often shown as GSM. GSM means grams per square meter. This number tells you how heavy and thick the paper is. If you need strong paper for hard jobs, pick a higher GSM. Thicker paper is stronger and lasts longer. It works well for packaging that must hold heavy things, like boxes or cartons.

A higher GSM means the paper is thicker and heavier.

Thick paper is stronger and lasts longer.

Use higher GSM for tough packaging jobs.

Thickness is also called caliper. It shows how dense the paper is. Even thickness helps with printing and rolling. Thickness changes how strong and bulky the paper feels. It also affects how the paper looks and prints.

Tip: Always check both GSM and thickness before picking paper. These numbers help you choose the right mix of strength and quality.

How Paper Weight Affects Performance

It is important to know how paper weight changes how it works. Heavy paper can hold more ink and lasts longer. It is best for business cards, brochures, and strong packaging. Thicker paper stops ink from bleeding through. It also holds ink better and does not change size much when wet.

| Performance Aspect | Lightweight Paper (60-80 gsm) | Medium-weight Paper (120-180 gsm) | Heavy-weight Paper (180+ gsm) |

| Ink Absorption | Soaks up more ink, colors may change | Soaks up less ink, better than light paper | Soaks up the least ink, holds color best |

| Show-through | Ink bleeds through a lot | Some ink bleeds through | Almost no ink bleeds through |

| Tear Resistance | Tears easily | Tears less easily | Hard to tear |

| Drying Time | Dries fast, may smear | Dries at a medium speed | Dries slowest |

| Dimensional Stability | Changes size 3-5% in humidity | Changes size 1-3% in humidity | Changes size less than 1% |

| Longevity | Does not last long | Lasts a medium time | Lasts the longest |

Choosing Heavy-Weight Papers

Pick the right heavy paper for your job. Corrugated board is strong for shipping heavy things. Solid Bleached Sulfate paperboard is good for boxes with heavy stuff inside. Heavy paper, like cardstock, costs more to mail. The United States Postal Service charges more for heavy paper. Small weight changes can make mailing cost more if you send many things.

Corrugated board is best for shipping heavy items.

Solid Bleached Sulfate paperboard is strong for heavy boxes.

Heavy paper costs more to mail, so plan your money.

Always match the paper weight and thickness to your project. This helps you get the best results and save money. Knowing how paper weight works helps you make better choices for packaging, printing, and other uses.

Kraft Paper Strength

Image Source: pexels

Features

You need strong packaging when you ship or store heavy items. Kraft paper gives you that strength. The long fibers in kraft paper make it tough and hard to tear. You can count on its high tear resistance and burst strength. These features help kraft paper stand up to rough handling and sharp objects. Natural kraft paper has the highest tear resistance and burst strength. You get a sturdy material that protects your goods.

Note: Kraft paper is more flexible than cardstock. You can bend it and wrap it around items without worrying about rips. It also resists punctures better than folding boxboard. This means you can use kraft paper for jobs where other papers might fail.

You will find different types of kraft paper for many uses. Some are thicker for extra strength. Others are softer for easy folding. You can choose the right type for your needs.

| Feature | Benefit |

| Long fibers | More durability |

| High tear resistance | Less chance of ripping |

| Burst strength | Handles heavy loads |

| Flexibility | Easy to wrap and fold |

Best Uses

Kraft paper works well for packaging bulky or heavy items. You see it in many industries. Here are some common uses:

Cement bags keep building materials safe during transport.

Animal feed bags protect feed from moisture and tearing.

Agricultural products like seeds, grains, and fertilizers stay secure in kraft paper packaging.

You can also use kraft paper for wrapping large parcels, making sturdy boxes, and lining containers. Its strength helps you move and store goods without damage.

Tip: If you want packaging that lasts, pick kraft paper for your heavy-duty needs. You get reliable protection and easy handling.

Heavy-Weight Papers for Applications

Packaging

You need heavy-weight paper to keep products safe and looking nice. Some types are better for hard jobs than others. You have a few strong choices:

Solid Bleached Sulfate (SBS) is good for fancy packaging and prints well, but it does not stop water.

Natural Kraft (SUS) and Coated Unbleached Kraft (CUK) are hard to tear. CUK also keeps out water.

Corrugated fiberboard is best for shipping and tough packaging. It keeps things safe and softens bumps.

Pick paper with high gsm for packaging. High gsm means the paper is thick and strong. This helps boxes and bags hold heavy things without breaking. You can use these papers for fancy store bags or special boxes that stand out.

Tip: Always look at the gsm number before picking paper. High gsm means the paper is stronger and protects better.

Printing

You want your printed things to look bright and last a long time. Thick paper with high gsm gives you the best look. Thick paper stays flat and does not bend when you print or touch it. A smooth and white surface makes colors and lines look sharp.

Use heavy-weight paper for business cards, brochures, and fancy finishes. Special machines can press designs into the paper for a fancy feel. High gsm paper also stops ink from going through, so your prints stay neat.

Note: Pick paper with the right gsm for your printing job. This helps your prints look good and last longer.

Industrial Uses

You need strong paper for work jobs when you want things to work well. Heavy-weight papers are made for strength and doing the job right. You might need a certain gsm for your work needs. These papers are good for lining boxes, making strong dividers, or wrapping big things.

Here is a table that shows what people need for different jobs:

| Application Type | User Requirements |

| Packaging | Needs to be strong and look good; great for fancy and special packaging |

| Printing | Needs special machines; good for pressed designs and fancy finishes |

| Industrial Uses | Needs to be strong and work well; may need a certain weight for the job |

You can use heavy-weight paper in many ways. It keeps things safe, helps with printing, and works for tough jobs. Always match the gsm to your job for the best results.

Selection Tips

Factors to Consider

When you pick strong paper for heavy-duty jobs, you want to make the best choice. You should look at several important things:

Paper weight: Heavier paper gives you more strength and lasts longer. This is best used for shipping, wrapping, and storing heavy items.

Durability: You need paper that can handle rough use. Strong paper is best used for packaging that faces bumps or drops.

Project requirements: Think about what you need the paper for. Some papers are best used for printing, while others are best used for wrapping or lining.

Cost and availability: You want to balance your budget with quality. A professional always checks if the paper is easy to get and fits the project cost.

A professional knows that choosing the right paper weight helps you get the best results. You should always match the paper to your job for the best used for each task.

Mistakes to Avoid

You can make mistakes if you do not plan. Many people pick paper that is too light for heavy jobs. This mistake can lead to tears and damage. A professional avoids using the wrong type of paper for the job. You should not ignore the weight or skip checking the durability. If you forget to check the best used for each paper, you may waste money and time. Always ask a professional if you are not sure.

Tip: Never pick paper just because it looks good. Always check the weight and what it is best used for before you buy.

Quick Checklist

Use this checklist to help you make a professional choice every time:

| Checklist Item | Description |

| Usage Analysis | Check how often and how hard you will use the paper. |

| Environmental Factors | Think about where you will use the paper, like in hot or wet places. |

| Criticality Assessment | Decide which jobs need the strongest paper for safety and quality. |

| Daily Maintenance | Look at the paper each day for signs of wear or damage. |

| Weekly Maintenance | Test the paper’s strength and replace if needed. |

| Monthly Maintenance | Review your paper choices and update if your needs change. |

| Annual Maintenance | Ask a professional to review your paper supply for the best used for jobs. |

| Tailoring Plans | Pick paper that matches your project and industry needs. |

A professional always checks this list to make sure the paper will give the best performance. You can trust these steps for choosing the right paper weight and type for any heavy-duty job.

You get good results for tough jobs by picking paper with the right weight and strength. Kraft paper is thick and strong. It works well for book covers and professional prints. Always look at GSM when you want nice print designs or fancy brochures.

Good paper makes your projects look better and last longer.

Try this easy checklist for special jobs:

Pick paper weight that fits your project.

Check if the paper is strong enough.

Choose top materials so your work lasts.

FAQ

What is the best way to choose cardstock for packaging?

You should use a paper weight guide. This guide helps you compare cardstock thickness and strength. You can pick heavy cardstock for strong boxes or medium-weight papers for lighter packaging. Always check the paper weight guide before you buy.

How does a paper weight guide help with printing projects?

A paper weight guide shows you which cardstock works best for printing. You can see which weight holds ink well and stays flat. You get better results when you match your project to the right cardstock using the paper weight guide.

Can you use heavy cardstock for luxury invitations?

You can use heavy cardstock for luxury invitations. This type of cardstock feels thick and looks fancy. A paper weight guide helps you pick the right weight for a luxury look. You impress guests with strong, beautiful invitations.

Why should you check the paper weight guide before buying cardstock?

You should check the paper weight guide to avoid mistakes. The guide shows you which cardstock fits your needs. You save money and get better results when you use the paper weight guide for every project.

What makes medium-weight papers different from heavy cardstock?

Medium-weight papers feel lighter than heavy cardstock. You use medium-weight papers for flyers or brochures. Heavy cardstock works better for sturdy items. A paper weight guide helps you see the difference and pick the right cardstock.

Tip: Always use a paper weight guide when you choose cardstock for any project. You get the best results and avoid problems.