You can see duplex board with grey back in lots of packaging and printing items. This material is strong and has two layers. The top layer lets you print good pictures. The grey back makes the board stronger. Many businesses use duplex board because it lasts long and has a smooth surface for designs.

The coated duplex board market is worth about USD 2.75 billion in 2024.

Experts think this will grow to almost USD 4.41 billion by 2033.

The market is growing at a rate of 6.08% each year.

People like duplex board with grey back because it helps the environment and fits new packaging needs.

Key Takeaways

Duplex board with grey back is tough and good for packing food, electronics, and cosmetics. It keeps products safe when they are shipped.

The smooth white side lets you print clearly. This makes your packaging look nice and professional.

Using duplex board saves money. It gives strong packaging that does not cost a lot.

This board is good for the environment. It often uses recycled stuff, which helps cut down on trash and protects nature.

When picking duplex board, think about how thick it is, how smooth it feels, and how much you want to spend. This helps you choose the best one for what you need.

What Is Duplex Board with Grey Back?

Duplex board with grey back is used a lot for packaging and printing. It has two layers you can see. The top layer is white and smooth, so printing looks nice. The back layer is grey and makes the board strong. This design is not like corrugated cardboard, which has a wavy middle layer. Duplex board gives you strength, good printing, and saves money. Many companies use it for food, cosmetics, and store products. It works well and is easy to recycle.

Key Features

There are many things that make duplex board special:

One side is white and coated. You can print clear pictures and bright colors on it.

The grey back keeps boxes stiff and helps them hold their shape when shipped.

Duplex board is lighter than other packaging materials. You can use it for small and light items without making them heavy.

It costs less when you need a lot of packaging. You save money but still get strong boxes.

Recycling is simple because duplex board has fewer layers and basic materials.

Tip: Pick duplex board if you want packaging that looks nice and stays strong.

Composition

Duplex board has different layers. Each layer does something important. Here is a table to show what each layer does:

| Layer | Material Type | Function |

| Top Layer | Coated white pulp | Smooth surface for printing |

| Core Layer | Recycled mixed pulp | Adds thickness and stiffness |

| Bottom Layer | Grey or uncoated pulp | Lowers cost, adds structural support |

Most duplex boards use recycled pulp for the main part. This helps the planet and keeps prices low. The coated top layer gives you a bright, clean space for printing. The grey back uses uncoated pulp, which is tough and strong.

Manufacturing

You can learn more about duplex board by seeing how it is made. There are several steps in the process:

Raw Material Collection: Factories get wood chips, recycled paper, and fibers to make pulp.

Pulping Process: Workers clean the pulp and take out dirt.

Formation of Slurry: The pulp mixes with water and turns into a thick liquid called slurry.

Board Formation: The slurry goes onto a screen. Water leaves, and a wet mat of fibers stays.

Layer Combination: Two layers of pulp join to make the board.

Pressing and Drying: Machines press and dry the board to make it flat and strong.

Surface Treatment and Finishing: The board may get a coating or be smoothed for better printing.

This way, you get duplex board that is smooth, strong, and ready to use. Using recycled pulp and smart ways to make it also makes duplex board better for the environment than other packaging materials.

Applications of Duplex Board

Image Source: pexels

Duplex board with grey back is used in many industries. It gives strong and cheap packaging. You can find it in food, electronics, and stores. More businesses use duplex board as they want better ways to protect products.

Packaging

Duplex board is used for lots of packaging. It is strong and keeps out moisture. This makes it good for food, electronics, and store items. The table below shows how different industries use duplex board:

| Industry | Usage Description |

| Food Industry | Used for packaging because it is strong and keeps out moisture. |

| Pharmaceuticals | Good for boxes in stores. |

| Electronics | Used to make products look nice. |

| Stationery | Used for many stationery items. |

| Toys | Used for toy packaging. |

| Processed Food | Used for packaging, but not for touching food directly. |

Duplex board helps keep things safe and looking nice. Its strength protects food and other items when shipped.

Printing

Printing companies like duplex board for packaging. It shows clear pictures and bright colors. It is cheap, which helps with big orders. Here are reasons printing experts pick duplex board:

Cost-effectiveness: You save money on packaging.

Sustainability: It uses recycled materials and helps the planet.

Strength: It keeps products safe when shipped and stored.

Versatility: You can use it for many packaging types, especially when you do not see the inside.

Duplex board works well for boxes, cartons, and displays. You can make designs that help products stand out.

Consumer Goods

Duplex board is used for electronics, cosmetics, and small store items. Its smooth surface is good for logos and product details. Many companies choose duplex board because it is cheap and works for many things. In medicine, duplex board is used for drug boxes and leaflets. These need clear writing and strong protection. Stores like duplex board because it helps make displays that get attention.

Other Uses

Duplex board is also used for other packaging. You may see it in folders, file covers, and gift boxes. It is easy to print on and strong. This makes it good for creative projects and special packaging. Duplex board gives both use and style in many ways.

Benefits of Duplex Board

If you pick duplex board for packaging, you get many good things. These benefits make duplex board a top choice for companies that want quality, value, and to help the planet.

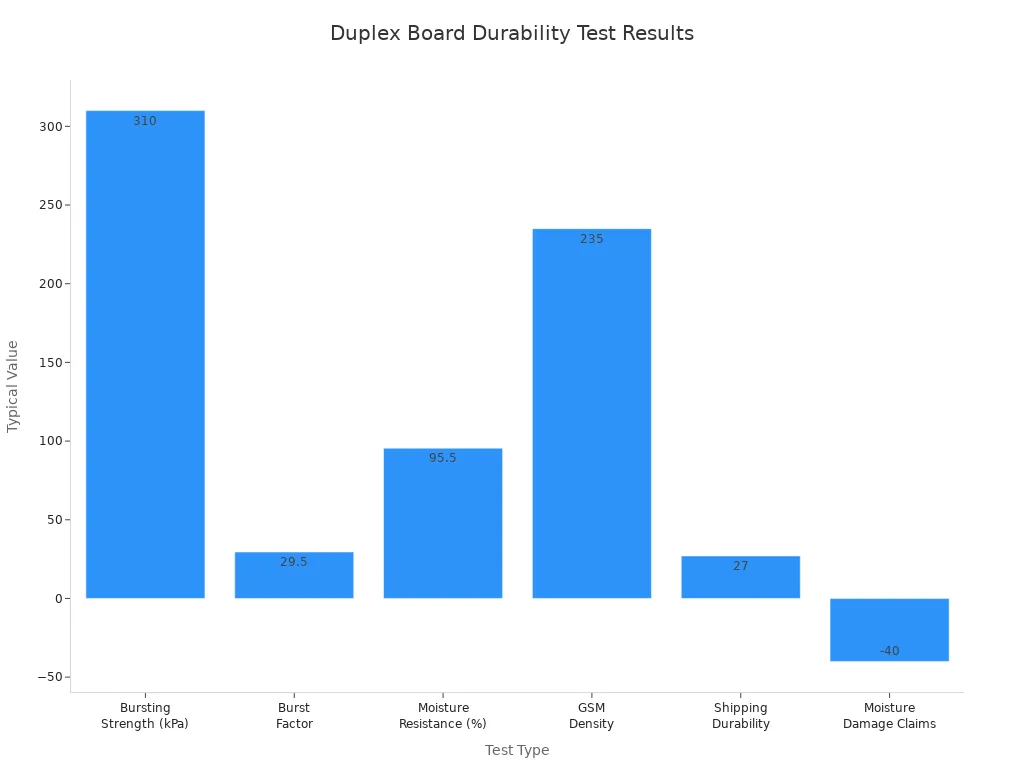

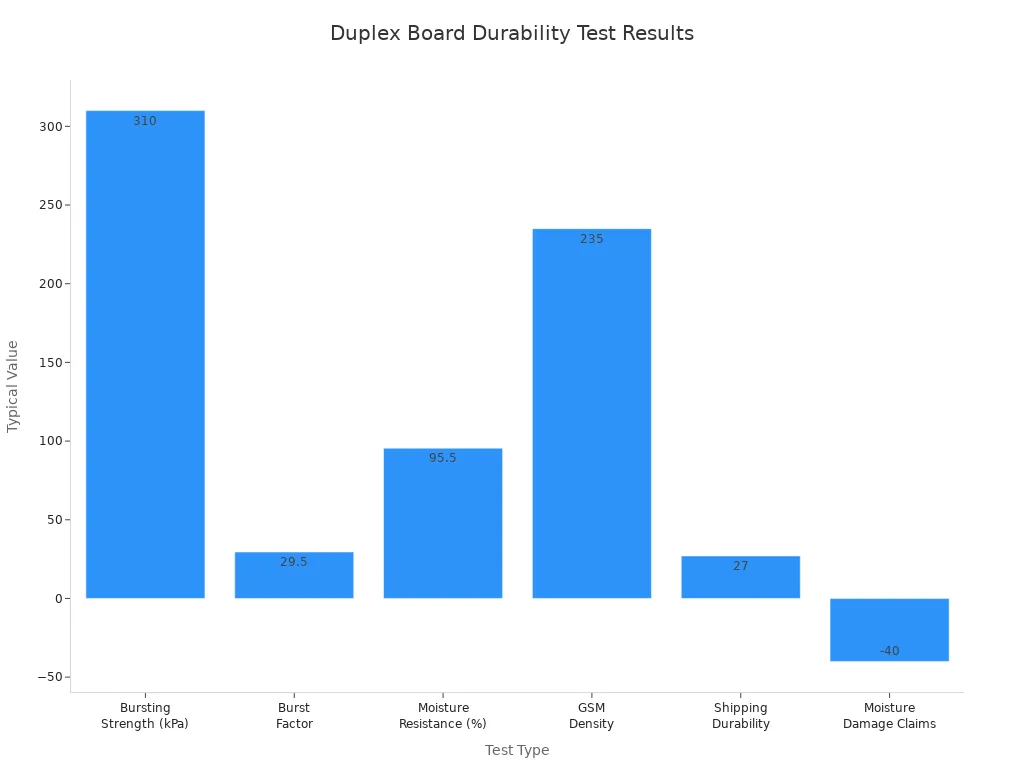

Strength and Durability

You need packaging that keeps products safe when shipped or stored. Duplex board is strong and lasts a long time. It does not break easily under pressure or get ruined by water. This means your items stay safe. Kraft back duplex board is even stronger, but duplex board with grey back is good for lighter packages. The table below shows how each type is different:

| Type of Duplex Board | Strength Comparison |

| Kraft Back Duplex Board | Stronger and more Durable |

| Grey Back Duplex Board | Less strong, Suitable for Lightweight Packaging |

Duplex board with grey back still passes important tests for strength. You can see the test results in this table:

| Test Type | Typical Value | What It Means |

| Bursting Strength (kPa) | 310 | Strong and reliable |

| Burst Factor | 28–31 | High resistance to pressure |

| Moisture Resistance (%) | 94–97 | Stays strong even in humid conditions |

| GSM Density | 220–250 (±2%) | Consistent thickness and weight |

| Shipping Durability | +27% improvement | Fewer damaged packages |

| Moisture Damage Claims | -40% | Less product loss in transit |

You can count on duplex board to protect your products. Its strength helps stop damage and loss. This saves you money.

Print Quality

If you want packaging that looks nice, duplex board is a good pick. The smooth white side lets you print sharp pictures and bright colors. You can use offset, inkjet, or laser printers. The even coating makes your packaging look great and helps your brand stand out. Here are some print quality features:

| Feature | Description |

| Good printability | Suitable for offset, inkjet, and laser printing |

| Uniform coating | Provides a fine look and enhances printing quality |

You can make designs that catch people’s eyes. The shiny coating makes your products look fancy.

Tip: Pick duplex board if you want packaging that is strong and looks good.

Cost-Effectiveness

You want to save money but still get good quality. Duplex board with grey back gives you both. It costs less than white back duplex board because the back is not smooth and white. This is smart when only the front side will show. Here are reasons why it saves money:

Kraft paper can be cheaper, but duplex board prints better and looks nicer. Duplex board is light, so shipping costs less. This helps you spend less and keep your products safe and looking good.

Eco-Friendly Value

Many companies want packaging that is good for the planet. Duplex board is a green choice. Most duplex board uses recycled paper, so it cuts down on waste. It breaks down naturally after use. You can find duplex board with important green certifications, like:

| Certification | Description |

| Ancient and Endangered Forest Friendly | Uses recycled fiber, FSC certified wood, and chlorine-free bleaching |

| ISO 14001 | Focuses on effective environmental management systems |

| Forest Stewardship Council (FSC) | Ensures responsible sourcing of wood products |

| ISO 9001 | Pertains to quality management systems |

| SGS | Certifies quality and safety standards |

Choosing duplex board with grey back helps you reach green goals. You show customers you care about the earth. This eco-friendly choice helps your brand and fits today’s packaging needs.

Note: Duplex board is a green choice that gives you strength, good printing, and helps the planet.

Selection Criteria

Picking the right duplex board helps you get good results. You should think about a few things before you choose.

Grade and Thickness

Duplex board comes in many grades and thicknesses. Now, you can find more choices in grammages and thicknesses. This means you can pick what fits your packaging best. If you choose the right thickness, you can save money and still get strong boxes. Thicker boards are stronger. Lighter boards cost less and work for small things.

There are more grammages and thicknesses now.

You can pick what matches your packaging.

The right thickness helps you save money and get good results.

Surface Finish

The surface finish changes how your printing looks. A smooth, uncoated board lets ink soak in well. This makes your prints look bright and clear. Uncoated boards look natural and work for some projects. You can use this board for art or for regular packaging.

Smooth, uncoated boards help ink go in better.

The board gives a plain background for designs.

The natural finish is good for some packaging.

Application Needs

You should match the board’s features to what you need. Look at the table below to see what is important:

| Criteria/Feature | Description |

| Quality Assurance | Makes sure you get the same high quality every time. |

| Strength and Durability | Protects your products during shipping and handling. |

| Printability | Lets you print logos, graphics, and text clearly. |

| Versatility | Works for many packaging and printing jobs. |

| Cost-effectiveness | Gives you good value for your money. |

| Eco-friendliness | Supports green goals with recycled materials. |

| GSM Range | Offers options from 180 to 500 GSM for different needs. |

| Coating Types | Includes LWC, HWC, and uncoated for different uses. |

| Pulp Quality | Affects how strong and green the board is. |

| Surface Smoothness | Helps your prints look sharp and clean. |

| Thickness Variations | Lets you pick the right size and weight for your products. |

Budget

Your budget is important when you choose. Duplex board with grey back costs less than white back. If you want to save money and do not need a fancy look, grey back is a good choice. The table below shows the main differences:

| Feature | Grey Back Board | White Back Board |

| Cost | More affordable for budget-conscious | Higher cost for premium appeal |

| Aesthetic Appeal | Suitable for non-premium goods | Cleaner and better for premium goods |

| Ideal Use | Everyday utility and affordability | Elevates brand image |

Tip: Pick grey back if you want to spend less and do not need a fancy look.

Supplier Choice

Choosing the right supplier helps you get good duplex board. You should check if they have a good name, good machines, and good quality checks. Use the table below to help you choose:

| Criteria | Description |

| Reputation and Experience | Choose suppliers with a strong track record. |

| Production Facilities and Technology | Look for modern equipment and methods. |

| Quality Management System | Check for ISO 9001 or similar certifications. |

| Raw Material Inspection | Make sure they use good fibers and additives. |

| Production Process Monitoring | They should watch key steps to keep quality high. |

| In-transit and Storage Protection | Good packaging and storage keep the board safe. |

| Final Product Inspection | They should check the board for strength and looks. |

| Continuous Communication | Stay in touch with your supplier for updates. |

| Industry Standards Compliance | Make sure they follow all rules and standards. |

If you look at these things, you can pick the best duplex board for your needs and budget.

Environmental Aspects

Recyclability

Picking packaging that is easy to recycle helps the earth. Duplex board is great because you can recycle it easily. Most duplex board uses waste paper and bamboo. These materials grow back and break down in nature. You do not have to worry about making more trash for landfills.

Here are ways duplex board helps the environment:

It uses waste paper and bamboo, so fewer trees get cut down.

Making duplex board uses less water and power, which saves energy.

Factories clean wastewater with new machines, so less pollution goes out.

Thin and light boards use fewer materials and save energy.

More recycling and reuse in factories means less trash leaves.

You can recycle duplex board after you use it. This makes it a smart pick for families and companies that care about nature. When you choose recyclable packaging, you help stop pollution and save resources. ♻️

Industry Standards

You want your packaging to follow the newest rules. Duplex board meets strict standards to stay safe and green. Many companies want packaging that uses less material and more recycled stuff.

Here are some new trends:

More people want packaging with lots of recycled material.

Companies make packaging lighter but still strong to save money.

New coatings and printing make packages look nicer and sell better.

Some packages have QR codes or NFC tags for extra info.

Businesses ask for special packaging to fit their products.

Duplex board has important certifications like FSC and ISO 14001. These show the board is made in a safe and green way. When you pick packaging with these standards, you show customers you care about the earth.

Duplex board with grey back is strong and good for the planet. You can use it for boxes, cartons, labels, posters, and notebooks. It has two layers that make it last longer and look nice when printed.

It saves money for many businesses.

The coated side makes pictures and words look bright.

Many kinds use recycled stuff, which helps the earth.

Before you pick one, think about what you need and how much you want to spend. Talk to good suppliers to get the right duplex board for your products.

FAQ

What is duplex board with grey back used for?

You can use duplex board with grey back for packaging, printing, and making boxes. Many companies choose it for food, toys, electronics, and cosmetics. It works well for items that need strong but light packaging.

Can you recycle duplex board with grey back?

Yes, you can recycle duplex board with grey back. Most of it comes from recycled paper. You help the environment when you recycle it after use. ♻️

Is duplex board safe for food packaging?

You can use duplex board for food packaging, but only if the food does not touch the board directly. Always check for food-safe certifications if you need direct contact.

How do you choose the right thickness?

Pick the thickness based on what you need to pack. Thicker boards give more strength for heavy items. Lighter boards work well for small or light products.

What printing methods work best on duplex board?

You can use offset, inkjet, or laser printing on duplex board. The smooth white surface helps your designs look sharp and colorful.