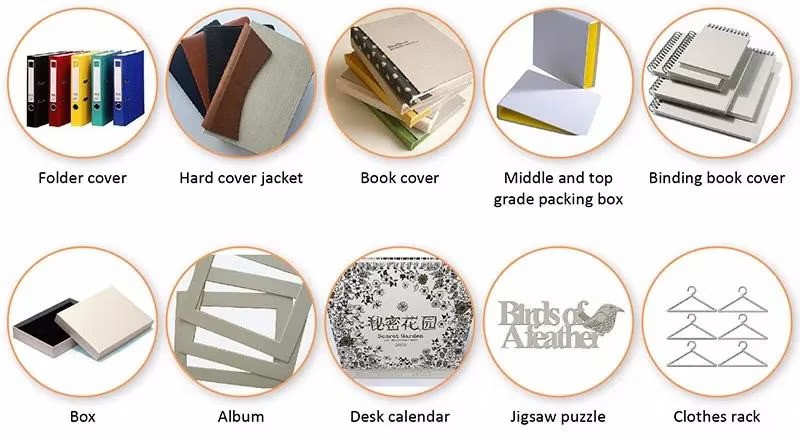

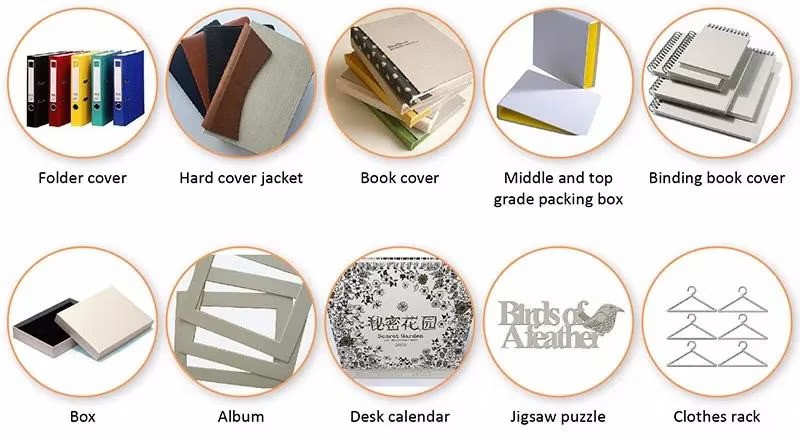

Grey board is made from recycled paper fibers. This makes it strong and good for the environment. It has a thick and hard shape. This helps it hold up many things. More than half of all packaging uses only recycled paperboard. Grey board is part of this group. Many industries use it for different jobs:

| Industry | Common Uses |

| Packaging | Making strong boxes, cartons, and other packaging. |

| Bookbinding | Used for covers of hardcover books to last longer. |

| Point-of-Sale | Making bright displays for stores to catch attention. |

| Stationery | Making notebooks, folders, and other items with a hard base. |

| Art and Craft | Used as a base for many craft projects because it is flexible. |

Knowing its features and how it is made helps you pick the best material for your needs.

Key Takeaways

Grey board uses only recycled paper fibers. This makes it strong and good for the environment.

Pick the right thickness for your project. Thick boards are best for packaging. Thin boards work well for crafts.

Grey board can be used in many ways. It is used for packaging, bookbinding, arts and crafts, and in factories.

Using grey board helps nature. It saves trees, water, and oil. You can recycle it after you use it.

You can add coatings for more protection. Coatings help with water resistance and make the surface smoother.

Grey Board Properties

Physical Features

You will notice that grey board stands out because of its thickness and solid feel. The thickness range gives you many choices for different projects. Here is a table showing the typical thickness options you can find:

| Thickness Range (mm) |

| 0.3 |

| 0.35 |

| 1.5 |

| 1.7 |

| 1.9 |

| 2 |

| 2.5 |

| 3 |

| 4 |

You can select a thickness that matches your needs. If you want a sturdy box, you might choose a thicker board. For crafts, a thinner sheet works well. The density of grey board also affects its quality. You can compare it with other paperboard materials in the table below:

| Material | Weight (GSM) | Density Comparison |

| Grey Hard Paperboard | 600 – 2000 | Denser than grey board paper |

| Grey Board Paper | 250 – 600 | Less dense than grey hard paperboard |

A denser board gives you more strength and better quality. You can rely on grey board for projects that need a tough and stable base.

Functional Qualities

Grey board offers you high quality in many ways. You can count on its strength and durability for packaging, book covers, and displays. The board resists bending and tearing, so your products stay safe. You can see how tensile strength varies by model in the table below:

| Model | Tensile Strength |

| Base Model | 2.5 N/m |

| Advanced Model | 3.0 N/m (+20%) |

| Pro Model | 4.0 N/m (+60%) |

If you need extra quality, you can choose a model with higher tensile strength. Additives can improve the board’s water resistance or surface smoothness. These changes help you get the right quality for your project. You can cut, stamp, ink, or paint grey board easily. This flexibility lets you use it for many creative and industrial tasks.

Tip: When you select grey board, check the thickness and tensile strength to match your project’s needs. Higher quality means better results.

Environmental Benefits

Grey board is an eco-friendly material. You help the planet when you choose it. The board uses 100% recycled paper pulp. You can recycle it again after use. It is biodegradable, so it breaks down naturally. Here are the main environmental benefits:

You save energy by using grey board. Recycled boards use a third less energy than boards made from new fibers. This makes grey board an eco-friendly choice for packaging and crafts. You support a cleaner environment and reduce waste when you pick this material.

Grey Board Manufacturing

Raw Materials

Grey board is made from recycled fibers. Most fibers come from waste paper. Old newspapers, cardboard, and packaging are used. This makes the material 100% recycled. Using these sources helps the environment. Grey chip board uses similar recycled paperboard. These sources help keep things sustainable.

Note: Using recycled fibers cuts down on waste and saves resources. Choosing this material is good for the planet.

Pulping Process

The raw material is broken down into pulp. Mechanical or chemical pulping methods are used. Here are the main steps:

The material is pulped and turned into fibers.

The pulp is cleaned to remove ink and glue.

The clean pulp is spread on a wire mesh to form a sheet.

The wet sheet is pressed and dried with rollers and heat.

A coating may be added to make it stronger and easier to print on.

The finished grey board is cut and packed for use.

Grey board’s pulping process is not the same as other paperboards. Wood chips are steamed, heated, and cooked in digesters. Chemicals are used to make the pulp stronger and more flexible. These chemicals are then washed and reused. This process gives grey board its special strength.

Pressing and Forming

The material is shaped by pressing it very hard. Heavy woodworking clamps press with about 1540 pounds of force. Vacuum bags can press with 13 to 14 psi. At sea level, air pressure is 1 atm or 14.7 psi. This pressure can press veneer layers.

Pressing temperature and time are controlled for the right thickness and strength. The table below shows how pressing changes the final product:

| Pressing Temperature (°C) | Pressing Time (min) | Resulting Thickness (mm) | Observations |

| 20-60 | Various | Not compressed | Loss of cohesion |

| 80 | 6 | Some binding | Insufficient stability |

| 120 | 0.5 | Some binding | Insufficient stability |

| 160 | Various | Firm, stiff, rigid | Stable boards obtained |

Higher temperatures and the right timing make a firm and stable board. Flexural strength goes up with lower thickness and higher density. Boards that are 5 mm thick reach a flexural strength of 10.06 N mm−2. This is almost as strong as the standard of 11.5 N mm−2 for boards between 3–6 mm.

Tip: For a strong and stable board, watch the pressing temperature and time.

Finishing Steps

The material is finished with treatments to make it better. You can pick from these options:

Transparent stains keep out moisture and let the board turn grey.

Semi-transparent stains show off the grain and protect well.

Solid-color stains give the most protection and let you pick the color.

Waxing makes the surface smooth and keeps out water and dirt.

Coating gives a nice finish and makes the board last longer. Water-based paints are a green choice.

| Treatment Type | Description |

| Transparent Stains | Changes the look a little, keeps out water, lets the board turn grey over time. |

| Semi-transparent Stains | Shows off the natural look, protects well, needs less redoing. |

| Solid-colour Stains | Gives the most protection, lets you pick the color, but hides some of the natural look. |

| Waxing | Adds a protective layer, keeps out water, dirt, and wear. |

| Coating | Makes the board look good, last longer, and water-based paints are better for the environment. |

Additives are also used when making the board. Urea formaldehyde is an adhesive. It helps the board stay strong and stiff. These finishing steps make grey board and recycled paperboard better for many uses.

Callout: The right finishing treatment makes your material last longer and look better.

Greyboard Applications

Greyboard is useful for many things. You can find it in packaging, books, crafts, and factories. It is easy to cut, stamp, ink, and paint. This makes it good for lots of different jobs.

Packaging Uses

Greyboard is strong and easy to shape for packaging. It is better than corrugated cardboard in some ways. The table below shows how greyboard helps with packaging:

| Feature | Greyboard Benefit |

| Durability | Can be used many times for strong packages |

| Custom Shapes | Easy to cut and fold for many shapes |

| Eco-Friendly | Made from recycled paper fibers |

| Cost | Cheaper than corrugated cardboard |

| Appearance | Looks nice for brands and stores |

You can use greyboard to make boxes and displays. Its smooth surface is good for printing logos and designs.

Bookbinding

Greyboard is important for making books. It is used for hardcover book covers. It keeps books safe and looking nice. You can also use chipboard for photo albums and folders. Here are some ways to use greyboard in bookbinding:

Make hardcovers for books with a shiny finish.

Give support to book jackets.

Help photo albums and scrapbooks keep their shape.

Pick the right thickness for each book.

Use glue lamination to make covers stronger.

Greyboard is dense and stiff, so books do not bend or warp. You can pick thicknesses from 0.3mm to 5mm for your project.

Arts and Crafts

Greyboard is great for creative projects. Artists and crafters like its flexible and plain color. Here are some ways to use greyboard in arts and crafts:

Make masks and decorate them with paint or markers.

Cut and decorate chipboard to make jewelry.

Design stencils for painting on many surfaces.

Build scrapbooks and photo frames.

Try DIY projects that need a strong base.

Crafters and artists use chipboard for many DIY projects. You can cut, shape, and glue it easily. Its gray color is a good base for painting and decorating.

Greyboard sheets help with many creative ideas. You can stamp, ink, or paint them for special designs.

Industrial Roles

Greyboard is also used in factories and industry. It is good for protecting machines and making custom parts. Its strength and flexibility make it a smart choice for tough jobs. Here are some industrial uses:

Protect machines and equipment with packaging.

Make custom parts from chipboard.

Save money on big projects.

Other materials like virgin fiber paperboards and plastics are sometimes used instead. These can be better for printing or keeping out water. But greyboard is still popular because it saves money and is good for the environment.

Advantages and Limitations

Key Benefits

Grey board has many good points for projects. Businesses like it because it saves money. It is also better for the environment. Here are some main benefits:

You pay less since it costs less than other packaging.

You help the earth by using recycled paper.

The material is biodegradable and easy to recycle.

The boards are strong and protect products during shipping.

You can use it for packaging, crafts, and book covers.

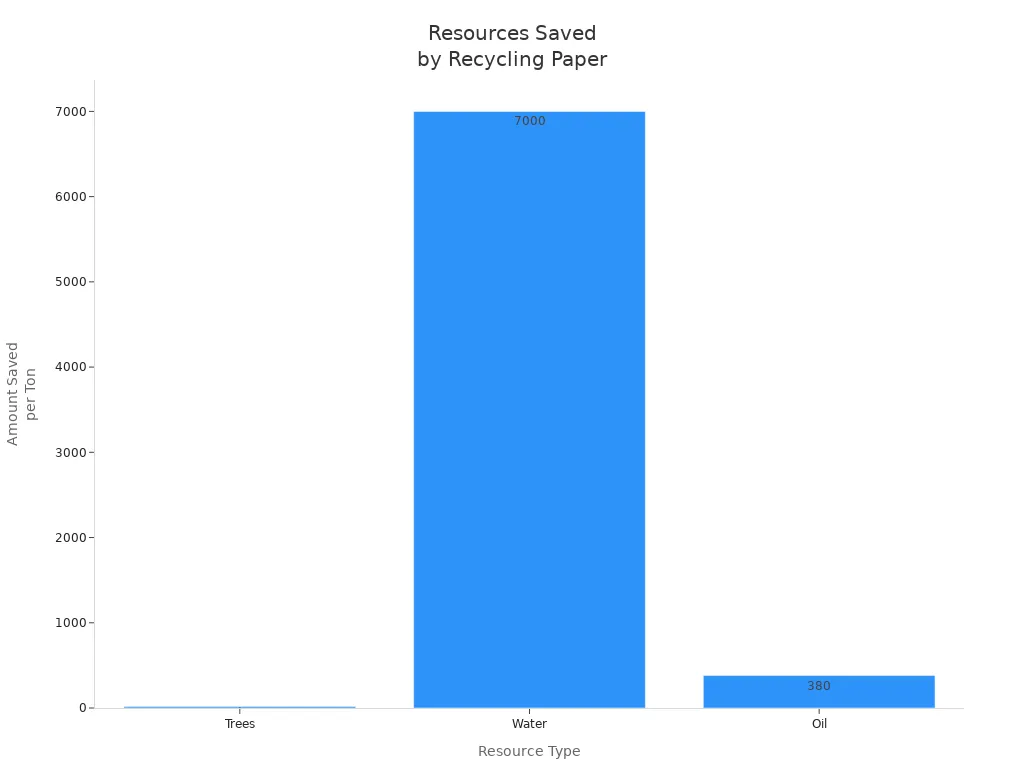

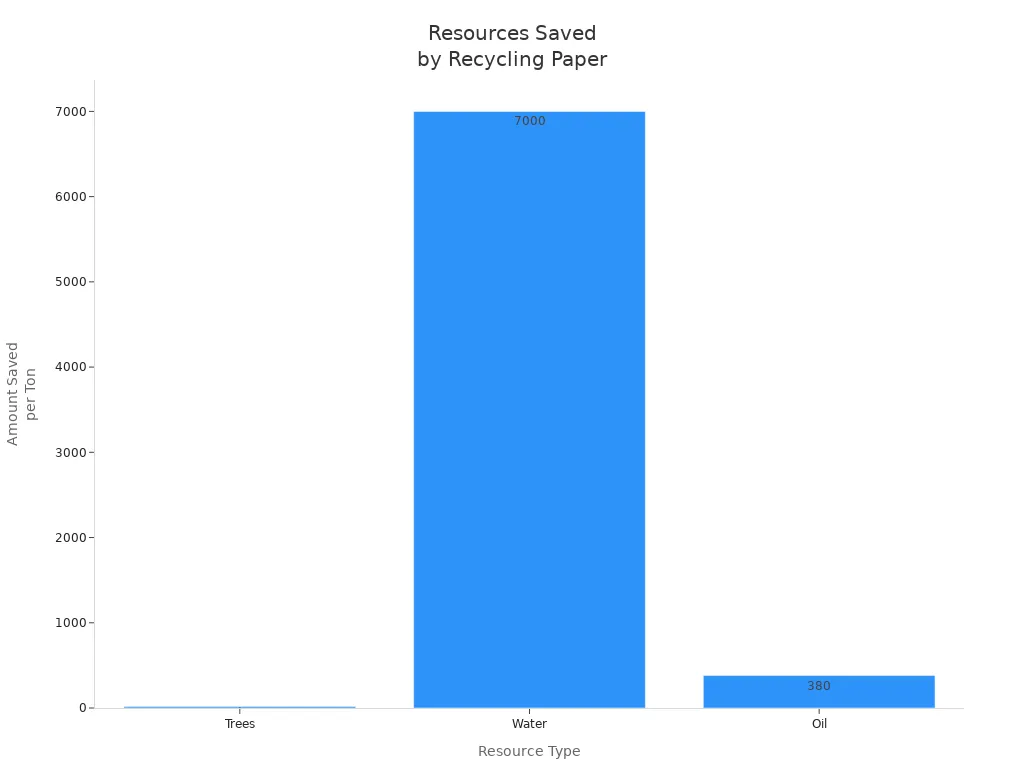

Using recycled paper saves important resources. The table below shows what you save for every ton of recycled paper:

| Resource Saved | Amount Saved per Ton of Recycled Paper |

| Trees | 17 |

| Water | 7,000 gallons |

| Oil | 380 gallons |

Tip: Choosing recycled materials helps the environment in a big way.

Common Drawbacks

There are some things to think about before you choose grey board. Some problems can change how well it works.

Water can cause trouble. Regular boards soak up water and get damaged.

Humid places can make the board weaker and less durable.

You might need special coatings to stop water from getting in.

The surface may not be as smooth, which can make printing harder.

Heavy loads or rough use can bend or tear the board.

New coatings help protect the board from water. You can find boards that work better for more jobs. Always check if you need extra protection for your project.

Note: For wet or humid places, pick boards with better coatings for more strength.

Grey board works well for lots of projects. It is tough and lasts a long time. It uses recycled fibers, which is good for the planet. You can pick the thickness and size you want. There are different coatings to choose from. This helps you find what fits your needs. Grey board does not cost much. It is easy to use and saves you money and time. Using recyclable materials helps keep the earth clean.

Strong and durable boards keep things safe.

You can change it to fit special needs.

Eco-friendly boards are better for nature.

Low price makes it a smart choice for factories.

Tip: Choose materials that are good for both quality and the environment for your next project.

FAQ

What is grey board made from?

You find grey board made from recycled paper fibers. Manufacturers use old newspapers, cardboard, and packaging waste. This process helps save resources and keeps the material eco-friendly.

How do you choose the right thickness for your project?

You should check what your project needs. Thicker grey board works best for boxes and book covers. Thinner sheets fit crafts or lightweight packaging. Always match thickness to the job.

Can you recycle grey board after use?

You can recycle grey board easily. Most recycling centers accept it. The board breaks down naturally, so you help reduce waste and protect the environment.

What is the difference between chipboard and greyboard?

You notice chipboard and greyboard look similar. Chipboard often uses mixed recycled fibers and may be lighter. Greyboard uses denser recycled pulp, giving it more strength for packaging and bookbinding.

Does grey board resist water?

Grey board does not resist water well without extra coatings. You can add wax or special finishes to protect it from moisture. For wet areas, choose boards with water-resistant treatments.