Paperboard is a strong and thick material. It is known for being tough and useful in many ways. You can find it in packaging, printing, and signs every day. Paperboard is not like regular paper or cardboard. It is stronger and keeps its shape better. Food and drink companies use almost half of all paperboard in the world.

| Industry | Percentage of Paperboard Usage |

| Food and Beverages | 48.0% |

The paperboard market around the world keeps getting bigger. This shows that people use paperboard for many things.

| Year | Market Size (USD million) |

| 2022 | 138,707.95 |

| 2030 | 214,492.80 |

Key Takeaways

Paperboard is tough and useful. People use it for packaging, printing, and signs. It lasts longer than regular paper and cardboard.

Picking the right paperboard is important. Solid Bleached Sulfate works well for fancy packaging. Folding Boxboard is good if you want to save money. The right paperboard makes products look better and keeps them safe.

Recycling paperboard helps the planet. About 68 out of 100 paperboard items get recycled. Using eco-friendly paperboard is good for nature and cuts down on trash.

Paperboard Overview

Definition

When you hear the word paperboard, you might think of something thicker than regular paper. That’s exactly right. In industry standards, paperboard is a paper product with a grammage that goes above 200 grams per square meter. Some groups, like the Confederation of European Paper Industries, say anything heavier than 220 grams per square meter counts as board. You’ll notice a few things that set paperboard apart:

It uses more long fibers than regular paper.

It usually doesn’t have fillers.

It feels sturdy and holds its shape well.

If you pick up a cereal box or a greeting card, you’re probably holding paperboard. You can see and feel the difference right away.

Key Features

Paperboard stands out because of its physical and mechanical properties. These features make it perfect for packaging, printing, and more. Here’s a quick look at what makes paperboard special:

| Property | Description |

| Thickness | Shows how thick the paperboard is. You measure it under certain pressure conditions. |

| Tightness | Tells you the weight per cubic centimeter. This shows how dense the material is. |

| Smoothness | Measures how much air passes through the surface. This tells you about the surface condition. |

Tip: If you want packaging that feels strong and looks smooth, paperboard is a great choice. You get both durability and a nice finish.

Paperboard vs. Paper and Cardboard

You might wonder how paperboard compares to regular paper and cardboard. Paperboard is thicker, stiffer, and more durable than paper. You’ll see it used for boxes, cartons, and other packaging that needs to hold its shape. Cardboard, on the other hand, is even heavier. It’s made of several layers, which gives it extra strength and rigidity. That’s why you see cardboard in shipping boxes and heavy-duty packaging.

Paperboard is lighter and more flexible than cardboard. You can fold it easily, and it works well for products that need a balance of strength and flexibility. Cardboard is better when you need something tough and sturdy. So, if you’re choosing between the three, think about what you need your packaging to do.

Types of Paperboard

When you look at packaging, you can see many kinds of paperboard. Each kind has its own good points and uses. Let’s talk about the main types you will find in the industry.

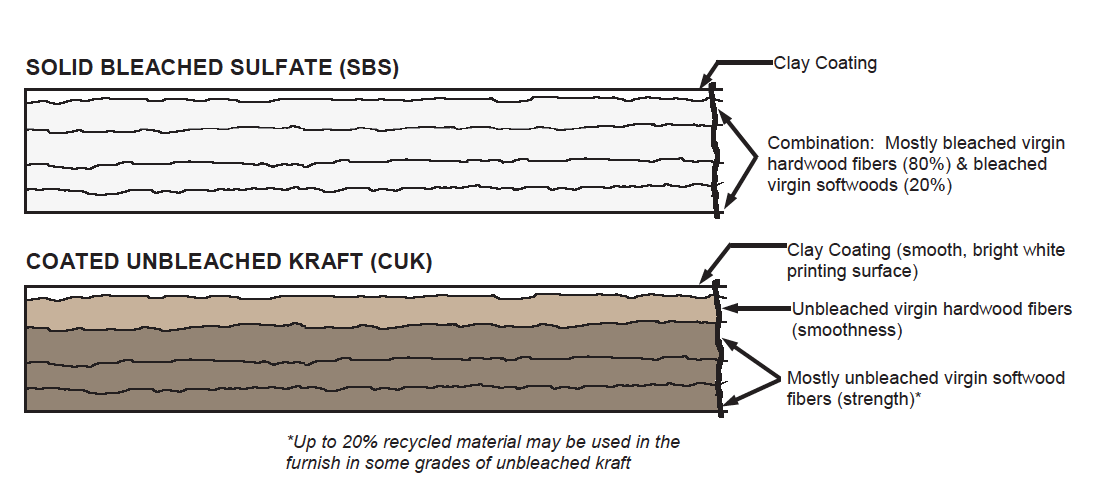

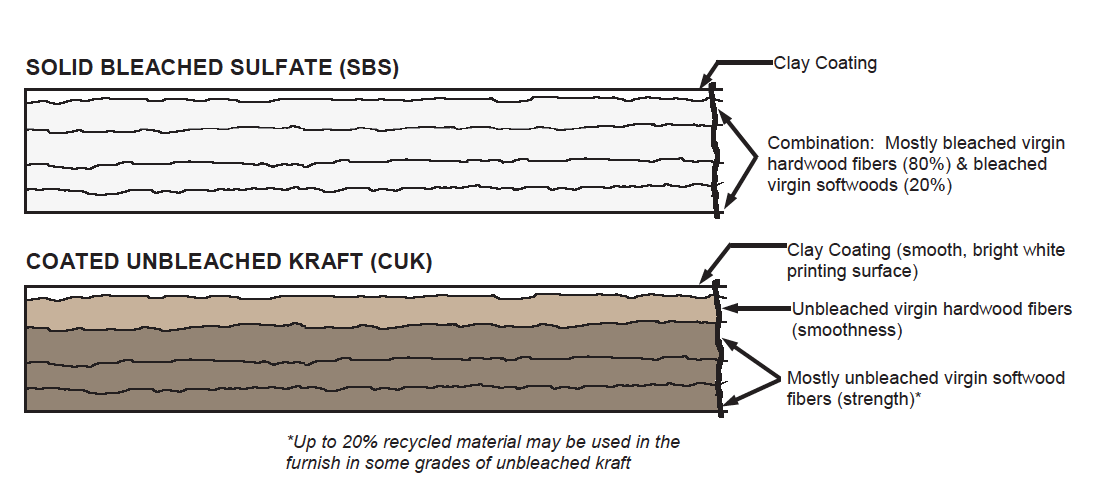

Solid Bleached Sulfate (SBS)

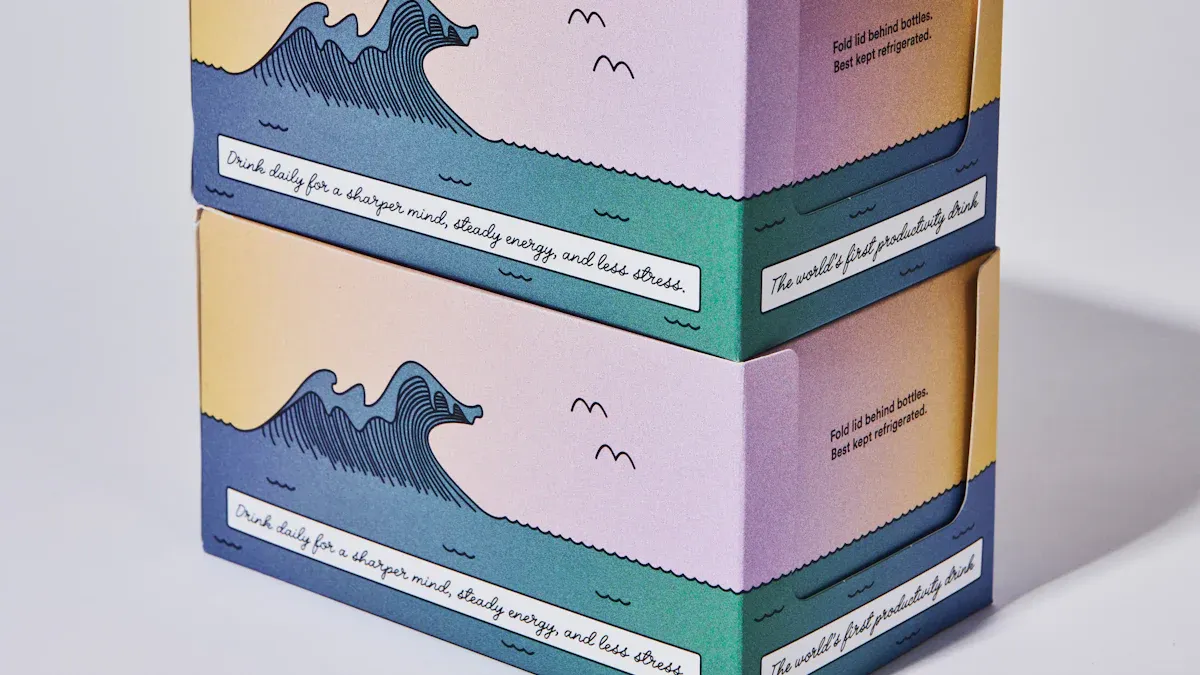

Solid Bleached Sulfate is used a lot in fancy packaging. It is made from pure bleached wood pulp. The sheet is bright white and very smooth. This makes it great for printing. The clay coating helps colors look bright and pictures look clear.

| Defining Characteristics | Typical Applications |

| Purity | Food packaging |

| Smoothness | Cosmetics |

| Moisture resistance | Pharmaceuticals |

| High gsm rating | Custom box packaging |

| Eco-friendly (FSC certified) | Premium packaging |

SBS paperboard is good for food, makeup, and medicine boxes. You can find it in ice cream cartons, cereal boxes, and gift boxes. The sheet bends easily, so you can fold it into many shapes. It always gives a nice, high-quality look.

Tip: If you want packaging that looks neat and feels strong, SBS is a great pick.

Here are some pros and cons:

| Advantages | Disadvantages |

| Premium quality | Not eco-friendly |

| Excellent printability | High cost compared to other grades |

| Superior strength and durability | Poor water resistance |

| Flexibility in packaging design and printing | Not suitable for heavy-duty protection |

| Popular in various industries (cosmetics, food) | Contributes to deforestation due to virgin fibers |

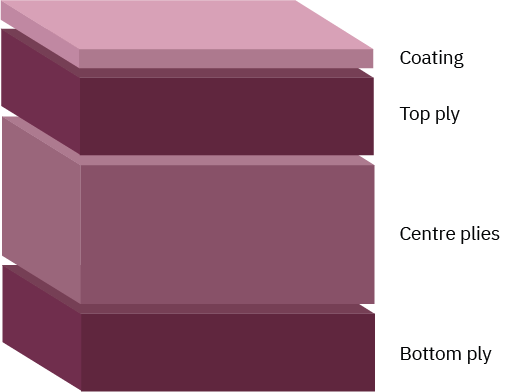

Folding Boxboard (FBB)

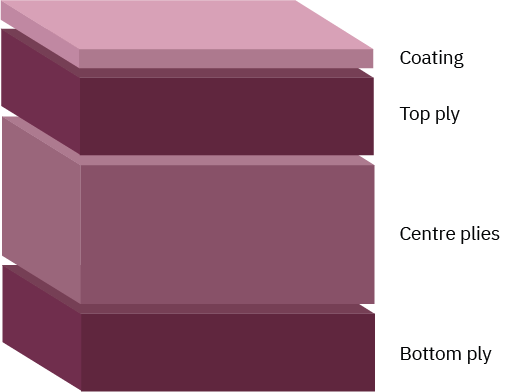

Folding Boxboard is another common type in packaging. It has many layers, with a strong core in the middle. The inside is a little yellow, which looks different. The outside is smooth and easy to print on, so pictures look nice.

| Unique Features of FBB | Common Uses of FBB |

| Multi-ply construction with a mechanical pulp core for enhanced rigidity | Pharmaceutical Packaging |

| Slightly yellowish inner layer for aesthetic appeal | Cosmetics & Beauty Products |

| Smooth, printable surface for high-quality graphics | Confectionery & Sweets |

| Lightweight yet strong | Tobacco Industry |

| Excellent barrier properties | Beverage Packaging |

| Cost-effective and sustainable | Frozen & Chilled Foods |

| Versatile for various shapes and sizes | Ready-to-Eat Meals |

You can find FBB in candy boxes, beauty products, and meal packages. The sheet is light, so shipping is cheaper. It is strong and keeps things safe. Many companies use FBB because it costs less and is better for the planet.

Here is how FBB and SBS are different:

| Property | SBS | FBB |

| Cost | Generally more expensive | More cost-effective |

| Strength | Excellent rigidity and durability | Suitable for various applications |

| Barrier Properties | Can be enhanced with coatings | Multilayered structure for better performance |

Note: FBB is a good choice if you want strong packaging and nice printing without spending a lot.

White Lined Chipboard (WLC)

White Lined Chipboard is made from recycled paper. It has layers of old paper and recycled fibers. The top and bottom are white, but the inside is gray. You can see WLC in cereal boxes, tissue boxes, and shoe boxes.

| Material Composition | Applications |

| Layers of waste paper | Packaging of frozen or chilled food |

| Recycled fibers | Cereal packaging |

| Coatings on top and reverse | Packaging for shoes, toys, and others |

WLC is light and strong. It is a cheap way to make everyday packaging. The sheet is good for backing boards, pads, and dividers. Many companies pick WLC because it is good for the environment and cuts down on trash.

Did you know? Using WLC can help lower pollution and support recycling.

Some common uses are:

Cereal boxes

Tissue boxes

Shoeboxes

Pads and partitions

Coated Paperboard

Coated paperboard is made to work well. It has a special layer on the surface. Wax, LDPE, or water-based coatings help keep out water and grease. The coating makes it great for food boxes, drink cartons, and things that need a barrier.

Wax gives a strong water barrier but makes recycling harder.

LDPE coating helps seal and keeps out grease.

Water-based coating is easy to change and better for nature.

You can find coated paperboard in milk cartons, juice boxes, and snack packs. The sheet keeps food fresh and safe. If you want a smooth surface for printing, coated paperboard is a good choice.

Tip: Pick coated paperboard if you need packaging that stops spills and water.

Specialty Paperboards

Some paperboards are made for special jobs. Thick chipboard is used in boxes for fancy goods, crates, and cold storage for vaccines. Clay coated paperboard is good for book covers and nice product boxes. Liquid packaging board is used for milk and juice cartons.

| Specialty Paperboard Type | Industry Uses |

| Thick Chipboard | Set-up boxes for high-end products, crating, skid pads, cold chain packaging for vaccines. |

| Clay Coated Paperboard | Premium packaging, product boxes, book covers. |

| Solid Bleached Sulfate (SBS) | Food and beverage packaging, cereal boxes, ice cream cartons. |

| Recycled Paperboard | Eco-friendly folding cartons, backing for notepads. |

| Folding Carton Board | Packaging for consumer goods, soap boxes, snack packaging. |

| Liquid Packaging Board | Milk cartons, juice boxes, drink pouches. |

You can also see specialty paperboards in appliances, building materials, signs, and containers. Some types protect corners and rolls when shipping. Others are used in special factories.

Callout: Specialty paperboards help you solve tricky packaging problems. You can always find the right sheet for your needs.

How Are Types of Paperboard Classified?

The industry uses different names for these types. Boxboard or cartonboard is for folding cartons and strong boxes. Containerboard is for corrugated fiberboard, which is used in shipping boxes. Binder’s board is for making books. Each paperboard type has its own job in packaging and printing.

| Type of Paperboard | Description | Common Applications |

| Solid Bleached Sulfate (SBS) | Premium grade with a clay-coated surface for high-quality printing. | Food packaging, cosmetics, dairy products, medical products, etc. |

| Coated Unbleached Kraft (CUK) | Made from unbleached virgin kraft fiber, known for strength and tear resistance. | Beverage containers, heavy-duty retail packaging, etc. |

| Coated Recycled Paperboard | Made from recycled fibers, finished with a clay coating for print performance. | Laundry soaps, dry bakery products, paper products, etc. |

| Non-Bending Chipboard | Thick paperboard grade used for rigid boxes, providing structure. | Small luxury goods in cosmetics, electronics, jewelry markets, etc. |

You will see corrugated types in shipping and strong packaging. Uncoated paperboard is used for simple packaging and printing. Coated paperboard gives extra protection and a smooth look. Each sheet is good for something different.

Reminder: When you pick a paperboard type, think about what your product needs. Do you want it strong, easy to print, or good for the planet? There is a sheet for every use.

Properties

Thickness and Density

When you hold a box, you can feel if it is thick or heavy. These are important things about paperboard. Thickness is measured in microns. One micron is 0.001 mm. If a paperboard has 200 microns, it is 0.2 mm thick. There are different ways to measure thickness and density:

| Measurement Method | Description |

| Single Sheet Thickness | Measures one sheet of paper or board. |

| Bulking Thickness | Measures a stack of paper sheets. |

| Density Calculations | Finds out how dense or bulky the sheet is. |

Thicker paperboard is usually stronger. Specialty packaging uses higher micron values.

Durability and Rigidity

You want packaging that lasts and keeps things safe. Durability and rigidity are very important. Companies use tests to check these things:

Bursting Strength Test checks if the paperboard can fold and stack.

Puncture Test shows if sharp things can poke through.

Edge Crush Test and Flat Crush Test see how much pressure the edges and surface can take.

Tear ‘Trouser’ Test checks how easy it is to tear the sheet.

Tip: Strong paperboard keeps your stuff safe when shipping and storing.

Foldability

Sometimes you need boxes that bend but do not break. Foldability lets you make boxes and cartons in many shapes. Good foldability means the paperboard does not crack or split when folded. This helps you make cool packaging that still protects your things.

Surface Finish

How paperboard looks and feels is important for brands and printing. You can pick from different finishes:

| Finish Type | Description | Applications |

| Matte Finish | Not shiny, soft surface | Luxury, food, pharmaceuticals |

| Gloss Finish | Shiny, bright colors, protects from scratches | Retail products |

| Embossed Finish | Raised effect, adds texture | High-end products |

| Spot UV | Shiny coating on certain spots, draws attention | Customer engagement |

| Foil Stamping | Adds foil for a fancy look | Luxury and gift packaging |

A smooth finish makes pictures and words stand out. Embossing and foil stamping make luxury items look special.

Applications

Image Source: unsplash

Packaging

Paperboard packaging is used almost everywhere. You see it in cereal boxes, toothpaste boxes, and snack boxes. These boxes keep products safe and make them look nice. Most food and drinks use paperboard for packaging. Personal care and online shopping also use it a lot. About one-third of all packaging comes from paperboard. Companies like it because it is easy to shape into boxes. You can make folding cartons and set-up boxes with it. Paperboard gives strong protection and helps brands look good. Big brands use paperboard to cut down on plastic waste. It also helps the planet by being more sustainable. Folding cartons are used for medicine, makeup, and food. Set-up boxes are good for gifts and fancy items. Corrugated boxes are used for shipping and storing things. Online stores use boxes and folding cartons to send products safely.

Tip: Paperboard packaging is good for the environment. It breaks down easily and can be recycled.

Printing

You see paperboard used in printing every day. Greeting cards and book covers use it for a smooth finish. Paperboard gives a great surface for printing. Colors look bright and images look sharp. Folding cartons and set-up boxes look neat and catch your eye. Paperboard is light and easy to cut. You can make custom boxes and folding cartons in any shape. Printing on paperboard costs less than other materials. You save money and still get good results.

Signage

Stores and events use paperboard for signs. You see price tags, banners, and posters made from folding cartons. Solid Bleached Sulfate paperboard is good for indoor signs and banners. Board stock is light and can be recycled. It works well for store displays. You get clear pictures and strong boxes that last. Corrugated and set-up boxes are also used for signs and displays.

| Type of Paperboard | Key Features | Ideal Uses |

| Solid Bleached Sulfate (SBS) | Thick, smooth, easy to print | Indoor banners, price signs |

| Board Stock | Lightweight, recyclable | Retail signage, event posters |

Other Uses

Paperboard is used for many other things. You find it in boxes for electronics, toys, and shoes. Set-up boxes keep breakable items safe. Corrugated boxes ship heavy products. Folding cartons are used for medicine and beauty products. Some brands use paperboard for toothbrushes, jewelry, and clothes. You see folding cartons and boxes in almost every store. Paperboard packaging is flexible and works for many needs.

Note: More people want paperboard packaging now. Using recycled paperboard helps protect the planet.

Sustainability

Recyclability

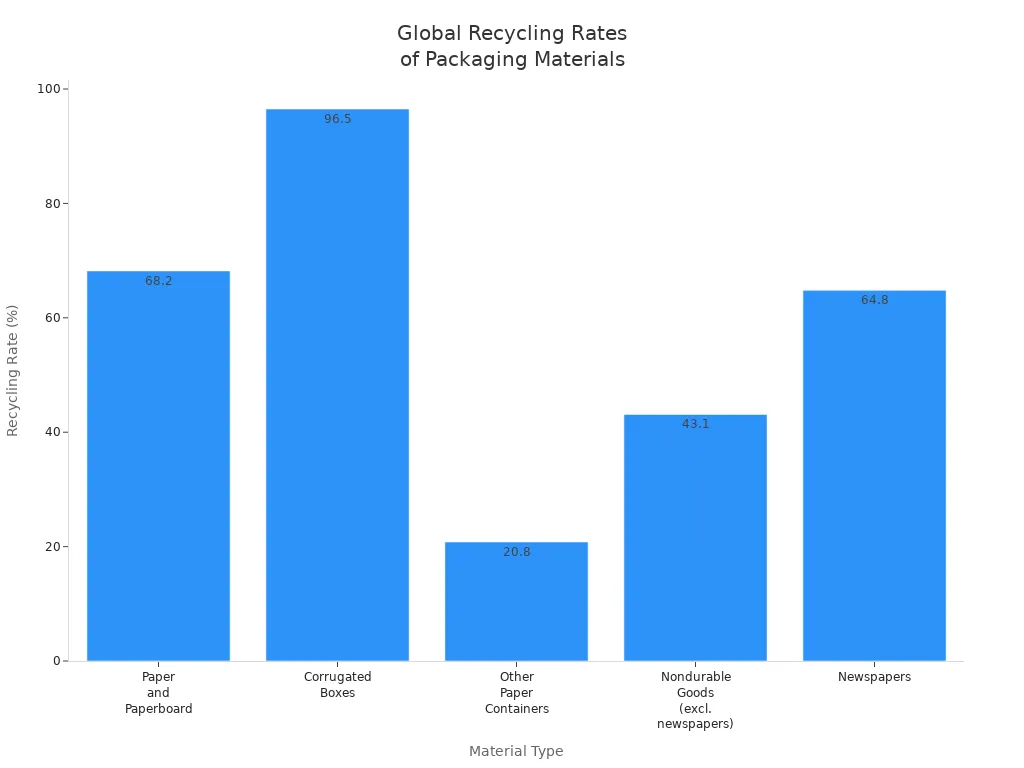

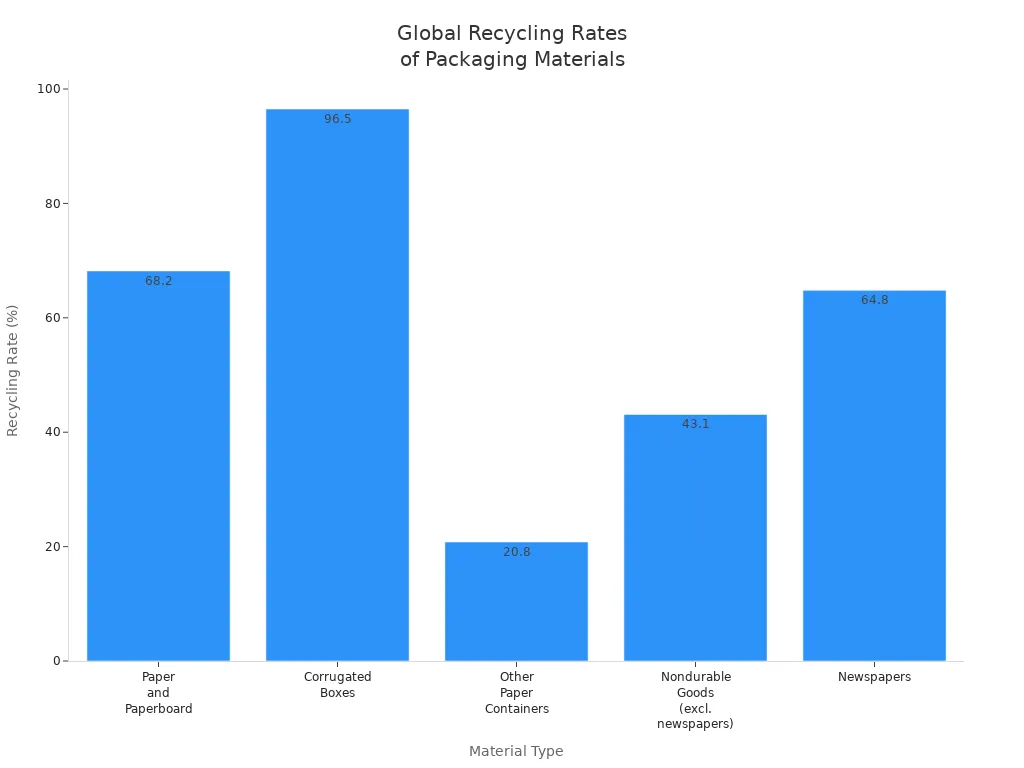

You see paperboard in many places. Most paperboard can be recycled. When you put a cereal box in the recycling bin, you help the planet. This keeps trash out of landfills. Paperboard has a recycling rate of 68.2%. This is higher than most other packaging materials. Corrugated boxes do even better. Their recycling rate is 96.5%. Here is how paperboard compares to other materials:

| Material Type | Recycling Rate (%) |

| Paper and Paperboard | 68.2 |

| Corrugated Boxes | 96.5 |

| Other Paper Containers | 20.8 |

| Nondurable Goods (excl. newspapers) | 43.1 |

| Newspapers | 64.8 |

Tip: Recycling paperboard helps the environment and cuts down on waste.

Renewable Resources

You may wonder where paperboard comes from. Most paperboard is made from trees. Trees are renewable if managed well. Makers use wood fibers from certified forests. They also use bagasse from sugarcane and recycled paper fiber. About 80% of U.S. paper mills use recycled fibers. The industry turns leftover wood into bioenergy. This makes production more eco-friendly.

| Resource Type | Sustainability Practices |

| Fresh Wood Fibers | Taken from forests that are managed well, used wisely, and recycled. |

| Bagasse | Comes from sugarcane, helps make paperboard more sustainable. |

| Recycled Paper Fiber | Used by most mills, helps save raw materials. |

| Renewable Bioenergy | Uses leftover wood for energy, supports a circular economy. |

Did you know? Sustainable packaging uses good sources and cares about the whole life of the product.

Eco-Friendly Innovations

You see more green packaging now. Companies use recyclable paperboard for boxes and displays. New technology makes paperboard stronger and better looking. This means packaging works well and helps the planet. Some brands use biodegradable materials and nanocellulose. These can replace plastic. More eco-friendly paperboard meets what people want and helps nature.

New paperboard technology makes packaging last longer and look nicer.

Makers spend money on research for better, greener packaging.

The industry works hard to protect the environment and create new ideas.

Callout: Picking recyclable and eco-friendly paperboard helps you help the planet.

Paperboard is strong and useful in many ways. It is good for the planet because it can be recycled. When you pick paperboard, you help save trees and cut down on trash.

Paperboard breaks down fast and is easy to recycle.

It comes from forests that grow back and helps lower pollution.

Companies that use green packaging get more trust from people.

| Organization | Description |

| Paperboard Packaging Alliance | Shares why paperboard packaging is good and gives helpful info. |

| GreenBlue | Works to make packaging better for the climate and the earth. |

FAQ

What is the difference between paperboard and cardboard?

You might think they are the same, but paperboard is lighter and easier to fold. Cardboard is thicker and works better for heavy-duty shipping boxes.

Can you recycle all types of paperboard?

Most paperboard can go in your recycling bin. Coated or waxed paperboard may need special recycling. Always check your local recycling rules.

Is paperboard safe for food packaging?

Yes! Food-grade paperboard keeps your snacks and meals safe. You see it in cereal boxes, milk cartons, and frozen food packages every day.