When you look at the SBS vs FBB paperboard comparison, you see big differences that can influence your packaging choices. SBS uses only chemical pulp, which makes it strong and smooth. You often see SBS in fancy products because it provides great print quality and a special appearance. In contrast, FBB is made from layers of chemical and mechanical pulps, which sometimes results in prints that are not as clear. Many people choose SBS for expensive packaging, even if it comes at a higher cost. Both types aim to be environmentally friendly, but their composition affects how you use them.

When making your decision, you must consider the SBS vs FBB paperboard comparison in terms of print quality, price, and environmental impact.

Key Takeaways

SBS paperboard works well for fancy packaging. It has a smooth surface and prints look great on it. FBB paperboard costs less and can be used in many ways. This makes it good for regular packaging. Both SBS and FBB can be recycled completely. This helps the environment. Think about what your product needs, like how it looks when printed or if it needs to stay dry, before you pick SBS or FBB. SBS usually costs more than FBB. So, you should think about your budget if you need to buy a lot.

SBS vs FBB Paperboard Comparison

Main Differences

When you compare sbs and fbb paperboard, you see each one is built differently and used for different things. The table below shows how they are not the same:

| Feature | SBS | FBB |

| Fiber Composition | 100% chemical pulp | Combination of chemical and mechanical pulp |

| Ply Structure | Can be single or multi-ply | Always multi-ply |

| Purpose | General use | Lightweight board for specific applications |

| Manufacturing Process | Chemical pulping | Mechanical and thermomechanical pulping |

SBS is special because it uses only chemical pulp. This makes the cartonboard very smooth and clean. FBB uses both chemical and mechanical pulps. The middle layer of FBB has mechanical pulp, and the outside layers have chemical pulp. Because of these layers, FBB can be used for many things.

If you look at how they work, you will see more differences. SBS has fibers that are packed tightly together. This makes it strong and good for printing small details. FBB is stiff and prints well too. Its layers make it a good choice for folding and cutting, and it saves money.

Here is another table to help you see how they work for different jobs:

| Feature | Solid Bleached Sulfate (SBS) | Folding Box Board (FBB) |

| Composition | Made entirely from bleached chemical pulp | Combines chemical and mechanical pulp |

| Fiber Structure | Tightly bonded, higher purity and strength | Multi-layer design, cost-effective |

| Print Performance | Excels with smooth surface for detailed graphics | Good for die-cutting and folding applications |

| Moisture Resistance | Better moisture resistance, suitable for extreme conditions | Adequate for functional packaging |

| Typical Applications | Refrigerated, pharmaceutical, medical packaging | Food boxes, medicine cartons, consumer goods |

SBS usually costs more than FBB. FBB is cheaper, so it is good for making lots of packages. The table below shows these price and strength differences:

| Property | SBS | FBB |

| Cost | Generally more expensive | More cost-effective |

| Strength | Excellent rigidity and durability | Suitable for various applications |

| Barrier Properties | Can be enhanced with coatings | Multilayered structure for better performance |

Why It Matters

It is important to know about sbs and fbb paperboard because your choice changes how your package looks, how much it costs, and how green it is. If you want sharp printing and a fancy look, SBS is a good pick. Its smooth surface helps you print clear pictures, which is great for luxury brands.

FBB has its own good points. Its layers make it stiff and nice for printing, but it costs less. Many brands pick FBB when they want good performance and a lower price. FBB is also good for the planet. It can be recycled and does not have harmful chemicals. This makes it a smart choice for brands that care about nature.

You should also think about keeping products safe. SBS is great at blocking out moisture, especially if you add coatings. This makes it good for cold or sensitive items. FBB’s layers help it work well for food and medicine boxes.

Tip: When you compare sbs and fbb paperboard, always pick the one that fits your product best. Think about how it prints, how much it costs, and if it is good for the environment before you choose.

Solid Bleached Sulfate Overview

Definition

Solid bleached sulphate is a very pure type of cartonboard. It is made from only bleached chemical pulp. The board is white all the way through. Solid bleached sulphate is clean and has no smell or taste. You can use it for things like chocolate, cosmetics, and cigarettes. Many people call it sbs. You can pick sbs with coating on one side (C1S) or both sides (C2S). The coating helps make printing look better.

Here is a table that explains what sbs is and its main features:

| Property/Definition | Description |

| Composition | Made from bleached chemical pulp |

| Coating | Mineral or synthetic coating on top (C1S) and sometimes on the back (C2S) |

| Density | Medium-density board |

| Printing Properties | Great for printing pictures and packaging designs |

| Color | White all the way through |

| Usability | Clean, pure, no smell or taste, good for products like cigarettes, chocolate, and cosmetics |

| Common Uses | Used for frozen food, shoes, and toy boxes |

Manufacturing Process

You can learn more about solid bleached sulphate by seeing how it is made. The process uses new wood fibers and several steps to make a strong, smooth board.

Pulping from new wood: Workers cut hardwood logs and turn them into pulp. This keeps sbs white and smooth.

Chemical pulping: Chemicals break down parts of the wood. This makes the fibers soft and bendy.

Bleaching: Safe chemicals make the pulp bright white. The board does not have a smell.

Making the board: Machines press, dry, and smooth the pulp into sheets. This gives you a strong, even surface.

Coating (C1S and C2S): Clay or other pigments cover one or both sides. This makes the board shiny and good for printing.

Tip: Pick solid bleached sulphate if you want a board that looks clean and prints well.

Key Properties

Solid bleached sulphate has many good things for packaging. The board is pure, white, and smooth. The surface is great for printing clear pictures. You can use sbs for packaging that needs to look fancy. The board is medium-density, so it is strong but not heavy. You can use it for frozen food, toys, and cosmetics. The coating choices help you get the finish you want.

SBS gives you better printing results.

The board is clean and safe for sensitive items.

You can pick different coatings for more protection or shine.

Solid bleached sulphate is special because it is pure, strong, and prints well. You can trust these features for high-quality packaging.

Folding Box Board Overview

Definition

Folding box board, also called FBB, has many layers. People use it for lots of packaging every day. The middle layer is made from mechanical pulp. The outside layers use chemical pulp. This design makes the board strong and light. FBB is easy to fold and cut. It works well for boxes that need to keep their shape. You can use folding box board for food, medicine, and personal care packages.

Manufacturing Process

You can learn about folding box board by seeing how it is made. The process uses different materials and steps to make good board.

Pulping: Workers turn fibers into pulp and bleach it for the layers.

Pressing: The pulp goes on a screen, drains, and presses into sheets.

Drying: Heated rollers take out water from the sheets.

Calendering: The dry sheets go through rollers to make them smooth.

Coating and Finishing: Coatings can make the board stronger and better.

Folding box board uses hardwood for a smooth surface. Softwood gives it strength. Sometimes, recycled fibers add support. Some makers use plant fibers like sugarcane or hemp too.

Key Properties

Folding box board has many good features for packaging. The board is stiff and does not bend easily. This helps protect products inside. The surface is bright and smooth. Printing looks clear and colorful on it. FBB takes in ink well, so designs look sharp. The board is strong and does not tear or break easily. It stays strong during shipping and handling. You can see these features in the table below:

| Property | Description |

| Bending | Very stiff and hard to bend |

| Brightness | Bright, white surface for printing |

| Caliper | Thickness stays the same |

| Tearing resistance | Hard to tear or break |

| Ink absorption | Takes in ink for sharp pictures |

| Moisture content | Keeps its shape in many conditions |

Note: Folding box board gives you strength, good printing, and saves money. You can trust FBB for many packaging jobs.

Structural and Physical Properties

Composition

SBS and FBB have different fiber structures. SBS uses only bleached chemical pulp. This makes it very pure and clean. FBB has chemical pulp on the outside and mechanical pulp in the middle. This layered design makes FBB lighter and saves money. The type of fibers changes how each board works for packaging.

Appearance

SBS has a very smooth and bright white surface. This helps you get sharp and clear prints. FBB also prints well, but its surface is a little rougher. This is because it has coarser fibers inside. You can see the difference in this table:

| Paperboard Type | Surface Smoothness | Print Quality |

| SBS | Higher | Better |

| FBB | Lower | Good |

SBS is very white and smooth. It makes prints shiny and colors look bright. It also uses less ink.

FBB prints well too, but is not as smooth because of its fibers.

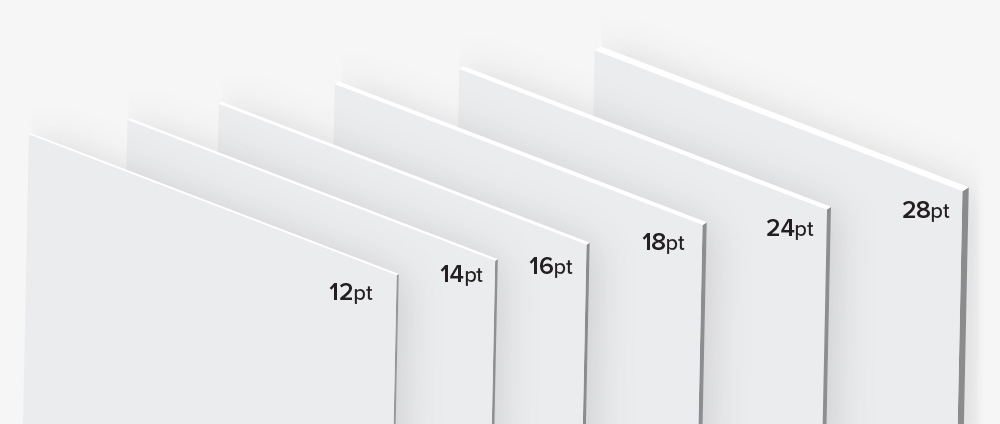

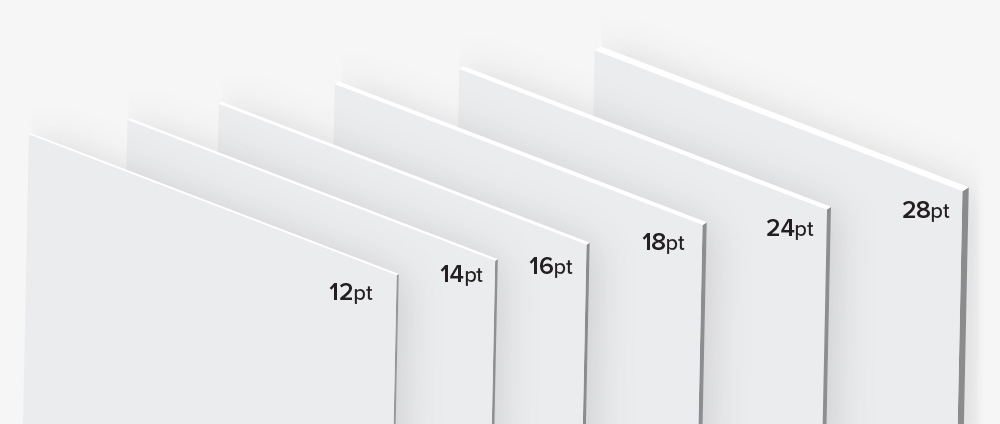

Strength and Rigidity

SBS is strong and holds up well when handled. Its dense build makes it stiff and tough. FBB has many layers, so it is stiff and does not bend easily. This helps keep products safe during shipping. Both types protect items well, but FBB is lighter and still strong.

Coating Options

You can pick different coatings for SBS and FBB. Clay coatings help prints look better and colors stand out. Polyethylene coatings keep out moisture, which is good for food or cold items. These coatings help you choose the right board for your product.

Tip: Always pick the right surface and coating for your needs. This helps your packaging look nice and keeps things safe.

Applications

Image Source: pexels

Premium Packaging Uses

SBS paperboard is used for fancy packaging. Its smooth, white surface looks nice and clean. Many makeup brands use SBS for pretty boxes. Electronics companies use SBS too. It keeps products safe and looks good in stores.

SBS gives strong protection and prints look great. Brands pick SBS when they want their products to stand out and feel special.

Everyday and High-Volume Uses

FBB paperboard is good for everyday packaging. You see it in food boxes like frozen meals and take-out containers. FBB is also used for health and beauty items and medicine cartons. Food and drink companies use FBB the most. Almost half of all paperboard packaging uses FBB. This shows FBB is important for safe and green food packaging.

FBB helps keep costs down and meets safety rules. Its design makes it easy to recycle and good for making lots of packages.

Industry Suitability

You should pick the right paperboard for your business. SBS works well for companies that want a fancy look and strong boxes. Food, drink, healthcare, and consumer goods brands often choose SBS. It is good for the planet, prints well, and can be used in many ways. These things help brands make packaging that looks nice and is eco-friendly.

FBB is best for companies that want to save money and help the environment. Food, personal care, and medicine brands use FBB because it saves energy and is better for nature. FBB’s price and performance make it great for making lots of packages.

Tip: Always think about how you will use the paperboard before you choose SBS or FBB. Pick the one that fits your product, your brand, and what you need.

Cost and Regional Trends

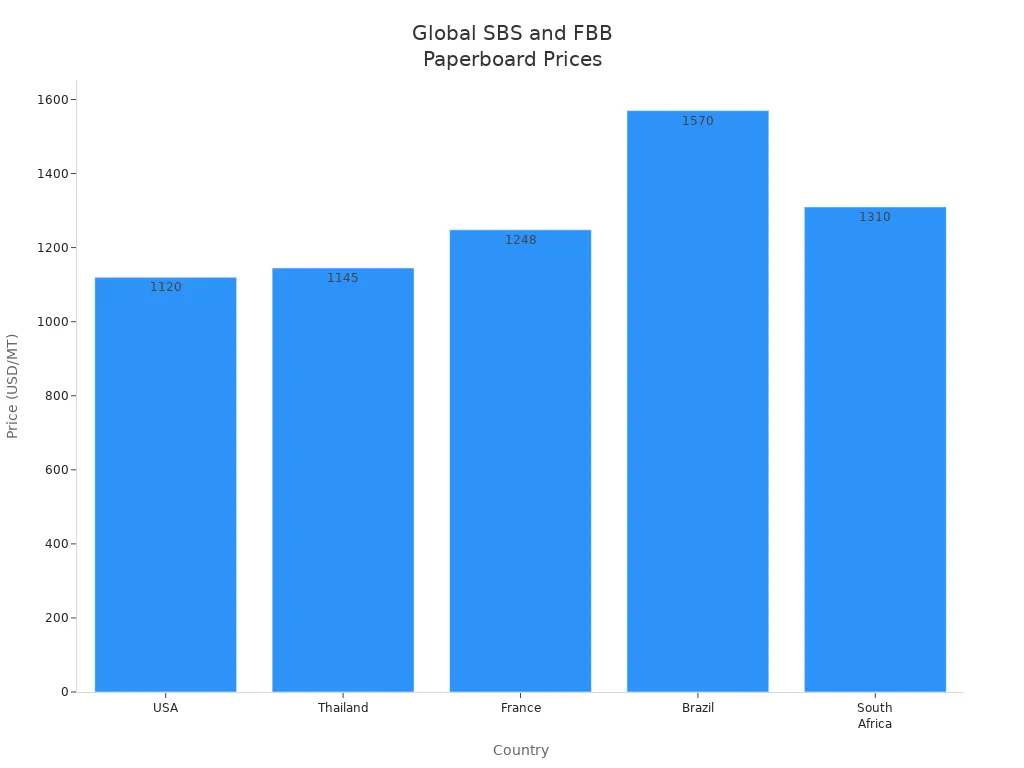

Pricing

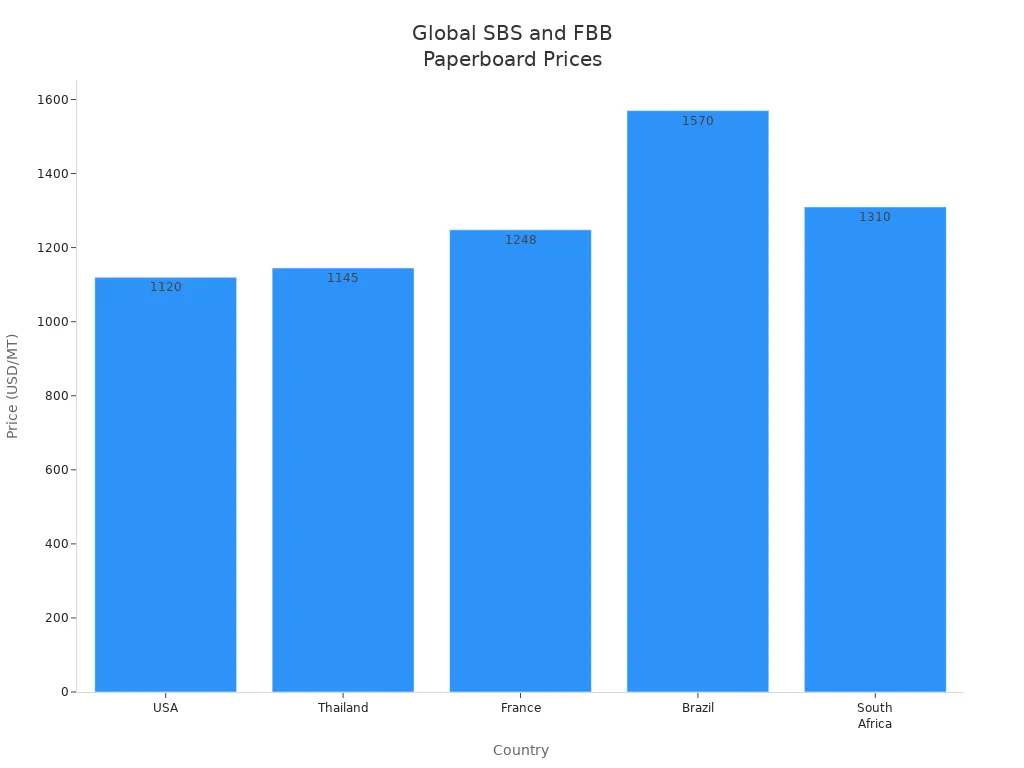

You need to know how much SBS and FBB paperboards cost in different countries. Prices can change based on where you buy them. The table below shows the price per metric ton (USD/MT) in some major markets:

| Country | Price (USD/MT) |

| USA | 1120 |

| Thailand | 1145 |

| France | 1248 |

| Brazil | 1570 |

| South Africa | 1310 |

You can see that prices are lowest in the USA and Thailand. Brazil has the highest price. These differences can affect your choice, especially if you need a lot of packaging.

Note: Prices may change over time. Always check with your supplier for the latest rates.

Regional Availability

Where you live or do business can change which paperboard you choose. In North America and Europe, you find strong demand for SBS and FBB. These regions have many packaging companies and advanced printing technology. You get more choices and better quality. In Asia Pacific, demand is growing fast. More people want packaged food and drinks. This growth means you can find more suppliers and better prices in the future.

Supply chain factors also matter. If you buy locally, you save on shipping and get your products faster. If you import, you may pay more and wait longer. Always think about where your supplier is and how it affects your costs.

Major Suppliers

You have many options when choosing a supplier for SBS and FBB paperboards. Some countries lead the market in making and shipping these products. Here are some key facts:

South Korea is the largest importer, with 22% of the market.

The United States follows with 20% of imports.

Thailand holds 19% of the import market.

The United States is the top exporter, with 83 shipments.

India and Brazil are also major exporters.

Tip: When picking a supplier, look at their market share and shipping record. This helps you get reliable and cost-effective paperboard for your packaging needs.

Sustainability Factors

Resource Efficiency

You want packaging that saves energy and resources. FBB is light, so it uses less energy to make. Most energy for FBB comes from sources that do not use fossil fuels. About 90% of the energy is fossil-free. This helps lower your carbon footprint when you pick FBB. If you change from SBS to FBB, you can cut your carbon footprint by more than half. If you use FBB instead of coated recycled board, you can lower carbon emissions by 60% or more. These choices help you be more sustainable and reach your environmental goals.

FBB is lighter, so it uses less energy.

Most energy for FBB does not use fossil fuels.

Switching to FBB can cut your carbon footprint by over 50%.

Using FBB instead of coated recycled board can lower emissions by 60% or more.

Environmental Impact

You care about the environment and want packaging that is easy to recycle. SBS and FBB are both easy to recycle. You can recycle both types, so less waste goes to landfills. The table below shows how SBS and FBB compare:

| Paperboard Type | Recyclability Rate |

| Solid Bleached Sulfate (SBS) | 100% |

| Folding Boxboard (FBB) | 100% |

Picking SBS or FBB gives you a better choice than plastic packaging. You help protect nature and support a cleaner future.

Regulatory Drivers

Governments and groups want better packaging choices. Many countries spend money on circular economies and green technology. Rules like extended producer responsibility and packaging waste laws make you use recyclable materials. The recycling rate for paper and cardboard packaging is 70.6%. This shows people support sustainability.

Governments want circular economies and green technology.

Extended producer responsibility and packaging waste rules help recycling.

The recycling rate for paper and cardboard packaging is 70.6%.

Many countries now have strict rules for single-use plastics. The European Union has new laws to cut plastic waste. This makes more people want paper packaging. People know more about plastic pollution, so they pick paper products as better options.

Strict rules limit single-use plastics.

The European Union wants less plastic waste.

More people want paper packaging because of plastic pollution.

Regulations help move toward paper-based packaging. These rules make you pick sustainable options. The demand for paper packaging keeps growing because of these changes.

Market Trends and Outlook

Global Growth

The paper and board market is getting bigger every year. It will go from about $205.6 billion in 2024 to $347.4 billion by 2033. This means it will grow by 6% each year. Many businesses help this market grow. Food, drinks, personal care, and cosmetics are the main ones. More people want packaging that is good for the planet. Companies now try to use eco-friendly and sustainable packaging. This change makes the market grow even faster.

Paper and paperboard packaging is growing fast.

Food and drink companies need more packaging.

Personal care and cosmetics brands use more paperboard.

Eco-friendly packaging is more popular now.

Note: The global paper and board market will keep growing as people pick sustainable packaging.

Regional Expansion

Asia Pacific is growing the fastest in this market. From 2025 to 2034, it will have the highest growth rate. Big countries like China and India need lots of packaging. People there buy more products every year. Companies in Asia Pacific are making more packaging. They help you get paper and paperboard packaging more easily.

Asia Pacific has the fastest market growth.

Big populations make more demand for packaging.

Companies work to improve production and supply.

More people can get paperboard packaging now.

Tip: If you want to join a fast-growing market, look at Asia Pacific for new chances.

Future Demand

You will see big changes in demand for SBS and FBB paperboards. Folding Box Board (FBB) is growing quickly. In 2023, FBB grew by 24% compared to last year. This happened because more people buy frozen foods and pick paper instead of plastic. Solid Bleached Sulfate (SBS) is not as popular now. Some companies, like Billerud, are changing their factories from SBS to FBB. This shows FBB will probably lead the market in the next five years.

The market is changing. Watch for more demand for FBB and less for SBS.

You have to make big choices when you pick SBS or FBB paperboard. SBS is smooth and strong, so it works well for fancy packaging. FBB is light and saves money, so it fits many products. Look at the table below to see what experts suggest:

| Paperboard Type | Key Characteristics | Typical Applications |

| SBS | Smooth, durable, premium look | Luxury, cosmetics, food, pharma |

| FBB | Lightweight, affordable, versatile | Everyday consumer goods |

Watch for new rules and what customers want. Pick the board that fits your needs for quality, price, and being good for the planet.

FAQ

What makes SBS better for luxury packaging?

You get a smooth, bright surface with SBS. This helps your prints look sharp and colorful. Many luxury brands use SBS because it gives products a premium feel and strong protection.

Is FBB safe for food packaging?

Yes, you can use FBB for food packaging. FBB meets strict safety standards. It does not add taste or smell to food. Many food brands trust FBB for boxes and cartons.

Can you recycle both SBS and FBB paperboard?

Yes, you can recycle both SBS and FBB. Both types have a 100% recyclability rate. You help reduce waste and support a cleaner environment when you recycle these paperboards.

Which is more cost-effective for large orders?

FBB usually costs less than SBS. You save money when you choose FBB for high-volume packaging. Many companies pick FBB for everyday products because it offers good performance at a lower price.

How do coatings affect SBS and FBB performance?

Coatings improve print quality and moisture resistance. You can choose clay or polyethylene coatings for both SBS and FBB. The right coating helps your packaging look better and last longer.