Release papers are very important in many industries. You can find them in labels, tapes, and medical products. New ideas in paper sil technology help companies make release papers faster. These ideas also help make the papers better. Companies now use new materials and smarter ways to work. This helps them save time and protect the environment.

Key Takeaways

Release papers are very important in many industries. These include medical, packaging, and e-commerce. The market for release papers will grow a lot by 2033.

New coating methods, like nanotechnology and PNC coatings, make release papers stronger. They help release papers last longer and not get damaged easily.

Automation in making release papers helps companies work faster. It also makes the quality better. Companies can meet customer needs quickly and waste less.

Eco-friendly materials, like bamboo and recycled fibers, are now more popular. These materials help companies be more sustainable. They also help lower harm to the environment.

The industry is moving to recyclable and compostable release liners. This change is because customers want it and new rules require less waste.

Industry Trends and Growth

Release Market Overview

The release liner industry is changing fast. Release liners are used in many things. They are in medical supplies, food packaging, and labels. E-commerce is making the market bigger. Companies want packaging that keeps products safe. They also want adhesives to stay fresh. Release liners help with labels and tapes. More release liners are used in hospitals and clinics.

The release liners market is growing around the world. Prices go up when more people want them. Latin America, Middle East & Africa, and Asia-Pacific are leading the growth. The table shows why these places are growing fast:

| Region | Contributing Factors |

| Latin America | More people use sustainable packaging. There are new rules for the environment. Exports are growing. |

| Middle East & Africa | More people use sustainable packaging. Food stores are growing. E-commerce is getting bigger. |

| Asia-Pacific | Factories are growing fast. Food packaging is needed more. Governments want more sustainability. |

Key Drivers and Challenges

People want packaging that works well and is good for the planet. Adhesives are used in many industries. The release liner industry grows as people need better packaging and medical supplies. Technology helps make better release liners. Prices rise when more people want them. The market grows by 5.8% each year.

There are some problems in the release liner industry. People want companies to help the environment. Companies use less water and energy now. They try to use wood from good forests and recycle more. There is a lot of competition from other countries. Companies work with research groups to make better release liners. They check quality very carefully. There are new rules for the industry. Companies must follow these rules. People want release liners made with eco-friendly materials.

The release liners market is changing to meet your needs. More adhesives are used in packaging, medical, and label products. Prices change when more people want them. The industry is working on being more sustainable and making better quality products.

Paper Sil Technology Advances

New Coating Methods

There are many new ways to coat paper sil. These new ways help you get better release papers. Technology makes coatings stronger and smarter. Some coatings protect against scratches and damage. Nanotechnology brings coatings that fix small damage by themselves. This means your release paper lasts longer. You use these coatings in packaging and oil and gas. Other industries use them too.

New protective polymer nanocomposite coatings give you more benefits. These coatings stop rust and fouling. Nanoparticles inside make coatings stronger and stable in heat. You see these coatings in aerospace, cars, and medicine.

Let’s look at how old coatings compare to new ones:

| Aspect | Traditional Coatings | New Coating Methods |

| Structure | Many layers | One layer with many jobs |

| Cost | High because of many layers | Lower because design is simple |

| Performance | Limited and can bend | Better with many jobs in one coat |

| Innovations | Each layer does one thing | Core-shell nanopigments add heat and rust resistance |

You get more value from new coating methods. You spend less and get better results. These new ideas help your release papers last longer and work better.

Process Automation

Process automation is changing how you make paper sil. Automation helps keep quality high and costs low. Machine vision systems check every sheet for problems. You get even release papers fast. This cuts waste and saves money.

AI and automation let you change production quickly. You can follow new trends and customer needs fast. Machine learning helps improve coating formulas and materials. Automated vision systems find problems right away. You make products faster and keep quality high.

Automation also helps you know when machines need fixing. You avoid long stops and save money. AI tools help match production with market demand. You stay ready for changes.

You use new tools like the SIL inline pump. This pump fits into your line easily. You do not need big changes or extra work. Customers say it works well and is easy to set up. Voith’s automation helps you make pulp better. These new ideas help you modernize your paper sil lines.

Tip: When you use automation, you get more even products and can make more easily. You meet customer needs faster and keep costs down.

You see new ideas in coating methods and automation. These changes help you make better paper sil products. You get stronger release papers and run your lines more smoothly.

Silicone Coated Release Liner Innovations

High-Speed Coating Solutions

Manufacturers now make silicone coated release liner much faster. Companies want to make more liners in less time. They use thin materials like polypropylene and polyester. These thin materials save space and lower shipping costs. Using less material also helps the environment.

Solventless silicone release coatings are now very popular. These coatings do not need organic solvents. This means there are fewer harmful emissions. The coatings cure quickly. You use less energy and your workplace is safer. Platinum-catalyzed and UV-curable solventless technologies help control coating weights. They also let you pick curing times. You can make liners for packaging and healthcare.

Dow SYL-OFF™ solutions help make production even faster. You get better control and faster curing. You can make more liners in less time. You also follow strict environmental rules.

Here is how high-speed coating solutions help you:

| Benefit | Description |

| Enhanced Production Throughput | Solutions enable faster curing at lower temperatures, improving efficiency in production lines. |

| Improved Product Quality | Better anchorage to paper at higher speeds minimizes defects and enhances overall quality. |

| Reduced Downtime | Minimizing misting prevents dusting, leading to less downtime during the manufacturing process. |

| Energy Efficiency | Solutions contribute to improved energy efficiency, reducing operational costs. |

| Sustainability | Lower environmental footprint by reducing waste and improving energy efficiency without compromise. |

You get liners that work fast and are high quality. You also help protect the planet.

Moisture Resistance Improvements

Water can damage release liners. You need liners that stay strong when wet. Manufacturers now use polyethylene coatings. These coatings block water from getting in. More film substrates are used now. These films resist moisture in humid places.

Silicone density optimization helps too. A thicker silicone layer stops water from getting in. Solventless silicone release coatings also help. They cure fast and use less energy. You can change them to fit what you need.

Recent innovations include:

Polyethylene coatings for better water resistance.

Film substrates that work well in humid areas.

Silicone density optimization for stronger protection.

Solventless silicone release coatings for fast curing and low energy use.

Glass fiber release paper gives even more moisture resistance. You do not have to worry about mold or mildew. Regular paper can bend when wet. Glass fiber mats stay strong and keep their shape. You use them in construction because they do not tear easily.

Tip: If you need liners for wet places, use glass fiber release paper. It lasts longer and protects better than regular paper.

Silicone coated release liner technology keeps getting better. You get products that last longer and work well in many places.

Material Innovation in Release Papers

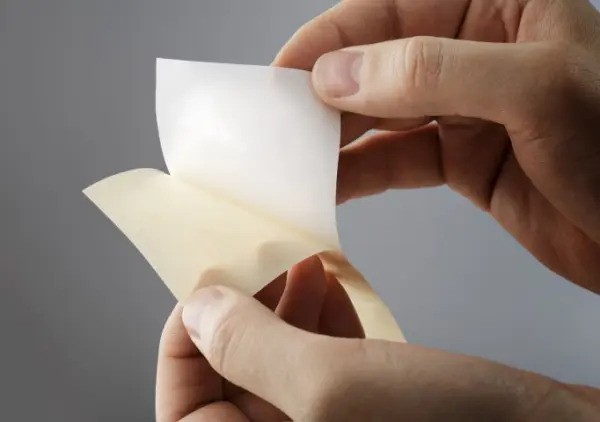

Image Source: pexels

Eco-Friendly Alternatives

You have many eco-friendly materials to pick from for release papers. These choices help protect the earth and support green packaging. Companies use eco-friendly release liners to cut waste and save resources. More people want products that are safe for nature, so you see more options now.

Bamboo grows fast and needs little water. You do not have to cut forests to use bamboo.

Recycled materials let you use less new wood. This helps keep more trees alive and supports recycling.

Algae makes paper that takes in carbon dioxide while growing. This makes your release liners even better for the planet.

Mycelium comes from fungi. It is a new eco-friendly choice for release liners and helps you find new ways to make paper.

Eco-friendly release liners work well in many industries. They last a long time and help the earth. By picking these liners, you help nature instead of using regular paper release liners.

Tip: If you choose eco-friendly release liners, you help keep air clean and forests healthy.

Alkylated Phosphorylated Fibers

Alkylated phosphorylated fibers help you make release papers that are better for the planet. These fibers give you a recyclable and green choice. You do not need silicone-based coatings anymore. Using alkylated phosphorylated fibers keeps recycling simple and clean. You also make your release papers easier to recycle. This helps you follow new rules and meet what customers want for eco-friendly release liners.

More companies use alkylated phosphorylated fibers for sustainable packaging. These fibers help you move away from regular paper release liners and pick green products. You make a smart choice for your business and for the earth.

Recyclable and Compostable Release Liners

Image Source: pexels

Sustainable Materials

More companies now use sustainable materials for release liners. These materials help protect nature and support green goals. Paper from bamboo or recycled fibers makes strong liners. These liners break down easily after use. Some liners have bio-based coatings from plants, not chemicals. Compostable liners go back to the earth after you use them. This means less trash goes to landfills.

Many brands now offer recyclable and compostable release liners. You can pick liners that help the planet and fit your needs. Research on bio-based and compostable liners is growing. This shows people want to lower harm to the environment. More customers ask for products that help the earth and support recycling.

Tip: If you choose recyclable and compostable release liners, you help cut pollution and make the future cleaner.

Industry Adoption

Big companies are starting to use recyclable and compostable release liners. Mondi has new liners for labels and tapes in the EU. Loparex grows its recycling program for siliconized paper liners in North America. UPM Raflatac begins a liner-to-liner recycling plan with brands in Europe. These actions show the industry wants to be more green.

| Company | Initiative Description | Region |

| Mondi | Launched recyclable and compostable release liners targeting label and tape converters | EU |

| Loparex | Expanded closed-loop recycling program for siliconized paper liners | North America |

| UPM Raflatac | Announced initiative for liner-to-liner recycling with brand owners | Europe |

You see more people want new and green liner materials. The need for these liners will grow fast. By picking recyclable and compostable release liners, you help the planet and support new rules.

Sustainability in Release Paper

Reducing Environmental Impact

You help make release paper better for the planet. Many companies want to lower harm to nature. They use liners that can be recycled or composted. These liners break down quickly and keep Earth clean. Factories now use eco-friendly ways to make products. These new ways use less water and energy. Companies pick materials from good sources.

Companies change plans to follow new rules. They use new technology to help the environment. Some companies change how they run their business. This helps support green goals. Investors want to see honest reports about climate actions. The SEC checks if these reports are true.

If you choose products made with care for the planet, you help make the world cleaner and safer.

Regulatory Trends

New rules are changing release paper for the future. These rules make companies work on being more green. Many countries want all packaging to be recyclable by 2030. The EU has a law for recyclable packaging. In the US, rules are different in each state. Some states want more green packaging than others. Companies now use paper instead of non-recyclable films.

Here is a table with some new rules:

| Regulatory Trend | Description |

| EU Packaging and Packaging Waste Regulation (PPWR) | By 2030, packaging must be recyclable. Non-recyclable materials are replaced with paper. |

| Extended Producer Responsibility (EPR) | US states have different rules for green packaging. |

| Shift to Recyclable Materials | Non-recyclable films are replaced with recyclable paper because of new rules. |

Sustainability is now needed, not just popular. Companies must follow these rules to keep working and help the planet.

Applications and Future Outlook

Self-Adhesive Labels and Tapes

You see self-adhesive labels and tapes almost everywhere. These products use advanced release paper technology to help you. You find them on food packages, drinks, and medicine bottles. Companies use these labels to keep things safe and share facts. You also see them in cars, computers, and buildings. Every industry needs packaging that is strong and keeps things neat.

Here is a table that shows how different industries use self-adhesive labels and tapes:

| Industry | Application Description |

| Packaging | Used for naming products and showing brands, especially in food, drinks, makeup, and medicine. |

| Automotive | Used to put parts together, keep heat out, and protect things because they stick well. |

| Electronics | Used to seal and connect parts in many devices. |

| Medical | Used to label medical tools, medicine, and lab samples where being exact matters. |

| Construction | Used for keeping heat in, sealing, and safety signs. |

| Logistics | Used to label and track boxes, making shipping easier and faster. |

| Graphics | Used for signs, ads, and decorations, mostly in stores and hotels. |

You depend on these labels for quick, safe, and easy packaging. Labels help you know what products are and give you details.

Emerging Uses

You will see more ways to use paper sil technology soon. The market for silk laminated paper will grow a lot. It will go from USD 2.3 billion in 2025 to USD 3.5 billion by 2035. This means you will see new packaging everywhere. Coated art paper will be the biggest part of the market. Business cards and branding will still be very important and make up a big part of what people want.

Here are some trends you should watch:

More people will want packaging that is good for the earth.

Smart packaging will let you get extra information and interact with products.

Digital printing will help make custom packages and cut down on waste.

Special features will help stop fake products and keep things safe.

Medical packaging will use more paper to help keep people safe.

Note: You can expect packaging to get smarter, safer, and better for the earth. Companies will use new technology to help you and follow new rules.

You will see packaging change in many ways. You will find more recycled, compostable, and smart packaging in stores and hospitals. The future of packaging will focus on safety, helping the planet, and new ideas.

You notice the release paper industry is changing quickly. New technology and eco-friendly materials are used more now. Companies want to make products faster and better. This means you get safer and greener items. People care more about the planet, so liners are now recyclable and biodegradable. In the future, you will see more new ideas and growth. There will also be some tough problems to solve.

| Opportunities | Challenges |

| Eco-friendly materials and smarter processes | Stricter rules on waste and emissions |

| Lower carbon footprint through new methods | Need for better recycling systems |

| Digital printing for custom, on-demand products | Meeting higher expectations for sustainability |

The future of release paper manufacturing will bring cool changes and new chances for you and the industry.

FAQ

What is paper sil technology?

Paper sil technology puts silicone coatings on paper. This makes the paper smooth and non-stick. Labels and tapes use this so they peel off easily. It also helps keep products clean.

Why do you need release liners in packaging?

Release liners protect sticky surfaces from dirt. They keep adhesives fresh and stop them from sticking to other things. You find them in labels, tapes, and medical items.

How do eco-friendly release liners help the environment?

Eco-friendly release liners use recycled or plant-based stuff. They help cut down waste and save resources. These liners break down faster and help with recycling.

Tip: Pick eco-friendly liners to help keep the planet clean.

Can you recycle silicone coated release liners?

Some silicone coated liners can be recycled now. You need to check your local recycling rules first. Many companies have programs to help you recycle these liners safely.

What industries use release paper the most?

Release paper is used in many industries:

Packaging

Medical

Automotive

Electronics

Construction

You see these papers in labels, tapes, and films every day.