Choosing the right sticker release paper can feel tricky, especially if you’re new to how to make stickers. You want to get the best results, so watch out for these common mistakes:

Use the right printer and ink for your sticker paper.

Adjust printer settings before printing.

Cut carefully with sharp tools.

Clean surfaces before applying stickers.

Store sticker release paper flat in a cool, dry spot.

Paying attention to these details will help your stickers look great and stick well.

Key Takeaways

Pick the best adhesive for your project. Water-based adhesives are good for inside use. Solvent-based and acrylic adhesives work better outside.

Choose the right release liner for your needs. Paper liners are good for the environment and save money. Film liners are strong and help you work fast and neat.

Pick the sticker paper finish that fits your project. Glossy paper makes colors look bright and is good for photos. Matte paper works well for labels with lots of words.

Try out your materials before you start a big project. Make sure stickers peel off easily and the adhesive stays on the sticker.

Think about where you will use your stickers. Humidity and temperature can change how stickers stick. Store your materials the right way.

Identify Adhesive and Project Needs

Types of Sticker Adhesives

When you start a sticker project, you should know which adhesive fits your needs. Each adhesive has special features. Some work better outside, while others are best for inside. Check out this table to see the most common types:

| Adhesive Type | Composition | Key Properties | Applications |

| Water-Based Adhesive | Water, polymers, and additives | Quick setting, strong initial bond, eco-friendly | Paper labels, general-purpose |

| Solvent-Based Adhesive | Organic solvents and synthetic resins | Durable, strong bond, may contain VOCs | Outdoor labels, industrial use |

| Acrylic Adhesive | Acrylic polymers | UV and moisture resistance, excellent bonding | Durable labels, automotive |

| Rubber-Based Adhesive | Natural or synthetic rubber | Flexible, good tack, works on uneven surfaces | Promotional stickers |

| Hot Melt Adhesive | Thermoplastic polymers | Fast bonding, reliable, versatile | High-speed labeling, packaging |

| Pressure-Sensitive Adhesive | Tacky at room temperature | Sticks instantly, no heat or solvents needed | Self-adhesive labels, tapes, stickers |

Pick the adhesive that matches your project. For outdoor stickers, acrylic or solvent-based adhesives are good because they handle weather and water. For quick indoor jobs, water-based adhesives work well.

Tip: Make sure your adhesive works with your release paper. The chemicals in the adhesive can change how easy it is to peel off the sticker and how well it sticks.

Application Requirements

Think about where you will use your sticker. Indoor and outdoor projects need different materials. Vinyl stickers are strong and do not get ruined by water, so they are great for outside. Paper stickers are light and cheap, so they are best for inside, but they do not like water.

Vinyl stickers: Made from PVC, water-resistant, strong for outdoor use.

Paper stickers: Light, low-cost, best for inside, not good with water.

The weather matters too. High humidity can make stickers curl or not stick. Heat can make adhesives soft, so stickers might fall off. Cold can make adhesives hard, so stickers may not stick well. Keep your sticker supplies in a cool, dry place to keep them nice.

Sticker Release Paper and Liner Types

Picking the right sticker release paper helps your project go smoothly. You want stickers that peel off easily and look nice. To do this, you should learn about different release liners and sticker paper finishes.

Paper vs. Film Release Liners

There are two main release liner types: paper and film. Each type works best for certain projects and has its own benefits.

Paper Release Liners

These are the most common. They work well for jobs that are not too fast. Paper release liners are simple to cut into shapes. Many people like them because they come from sources you can trace. They are also better for the planet. If you want something cheap and easy to recycle, pick paper release liners. Almost half of all projects use paper release liners because they save money and work for many uses.

Film Release Liners

These are made from PET plastic. Film release liners are tough and do not get ruined by water. They are best for fast jobs and give very exact results. Some film release liners can be recycled, which is good for the earth. If you need strong liners and perfect cuts, choose film release liners. More people are using film release liners because they work so well.

Polycoated Paper and Metalized Film

Polycoated paper has a thin plastic layer. This makes it better with water than regular paper. Metalized film liners have a shiny metal layer. They are stronger and protect against water. Use these for special projects that need extra strength.

Note: The release liner you pick can change how easy it is to recycle your sticker paper. Some new liners, like Barrier-Coated Kraft or Zero Waste Release Liners, are made to be recycled. These help you make less trash and keep your project green.

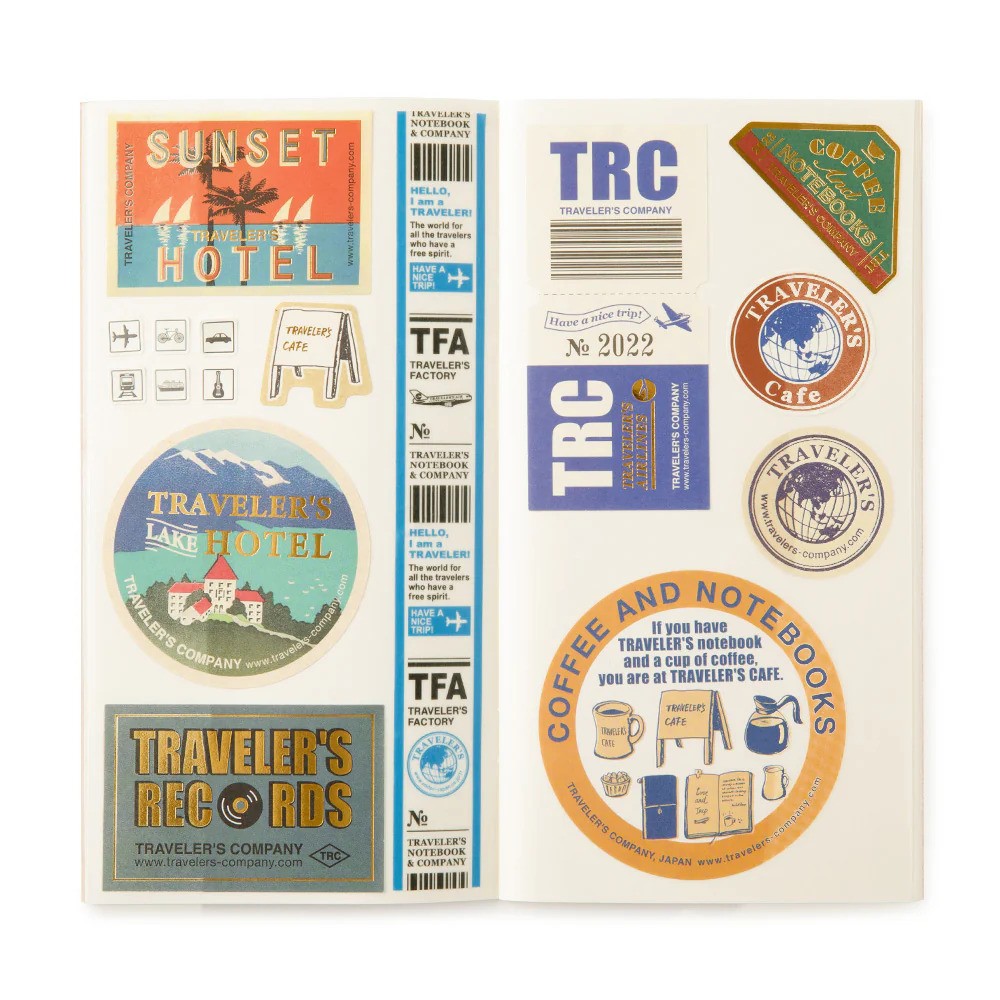

Matte and Glossy Sticker Paper

Sticker paper comes in different finishes. The finish you pick changes how your stickers look and feel. It also affects how easy they are to read and how long they last.

| Feature | Matte finish | Glossy finish |

| Visual appearance | Soft, not shiny, looks fancy | Bright, shiny, grabs attention |

| Durability | Does not show fingerprints or scratches | Protects against water, lasts longer |

| Maintenance | Stays clean longer, needs less cleaning | Shows fingerprints, needs more cleaning |

| Readability | No glare, easy to read | Can glare, harder to read sometimes |

| Usability | Smooth, easy to write on | Slick, hard to write on, ink can smear |

| Cost | Often costs more than glossy | Usually cheaper, depends on quality |

| Ideal for | Menus, cards, labels with lots of text | Photos, ads, prints with bright colors |

Glossy sticker paper makes colors look bright and sharp. It helps designs stand out. If you want stickers that get noticed, use glossy sticker paper. Matte sticker paper looks soft and fancy. It is great for labels with lots of words because it does not shine and is easy to read.

Glossy finishes make colors pop and shine.

Matte finishes look fancy and do not reflect light.

The finish you pick can change how strong and water-resistant your sticker paper is.

If you want the best sticker paper for photos or colorful art, glossy sticker paper makes pictures look clear and bright. For business cards, menus, or labels with lots of words, matte sticker paper is the best sticker paper because it is easy to read and does not show fingerprints.

Tip: Always match your sticker release paper and finish to your project. For outdoor stickers, use a film release liner with glossy sticker paper. For labels or business cards, matte sticker paper with a paper release liner is often the best sticker paper.

You have lots of choices for sticker paper and release liners. Think about what matters most for your project—price, look, strength, or recycling. Picking the best sticker paper and release liner helps your stickers look good and work well every time.

Key Selection Factors

Release Force and Durability

When you choose sticker release paper, think about release force. Release force is how hard it is to peel off the sticker. If it is too strong, you might rip the sticker or have trouble taking it off. If it is too weak, the sticker might fall off before you want.

Manufacturers test release force with special tools. These tests make sure the sticker release paper works the same every time. Here is a table that shows some of these tests:

| TLMI Standard | Description |

| TLMI L-IA1 | Checks how well product label face stocks stick and peel. |

| TLMI L-IA2 | Checks how well release liners stop stickers from sticking too soon. |

| TLMI L-IA3 | Checks how much force is needed to peel liners at different speeds. |

Pick a release force that fits your project. Stickers for kids should peel off easily. Labels for machines need to stay on until someone removes them.

Durability is important too. You want your sticker to last as long as you need. Many things can change how long a sticker lasts:

Sticker materials are important for how long stickers last.

The ink you use can help stickers not fade or get ruined.

The way you print can make stickers stronger.

Laminates protect stickers from sun, water, and scratches.

If you want your sticker to last outside, use strong sticker material and add a laminate. For inside, you can use lighter sticker material and skip extra layers.

Tip: Always try out your sticker material before a big project. Peel, stick, and rub the sticker to see if it works well.

Surface Texture and Sticker Material

Surface texture is also important. The feel of the release paper changes how well the sticker sticks and peels. Smooth surfaces let the adhesive spread and stick tightly. Rough surfaces give the adhesive more places to hold on, which helps stickers stay on bumpy things.

Smooth surfaces like glass and metal help chemical adhesion. The adhesive touches every part, so the sticker sticks well. Rough surfaces, like outdoor gear, use mechanical adhesion. The adhesive grabs onto bumps and dips, so the sticker stays put.

Here is a table that shows how sticker materials work with different textures:

| Label Type | Surface Texture | Optimal Use Case |

| Semigloss | Smooth | Good for bright colors and general use |

| Gloss | Smooth | Best for sharp images and graphics |

| Textured | Textured | Great for fancy wine bottles |

| Linen | Textured | Looks nice on special items |

| Felt | Textured | Feels different for cool branding |

| Estate | Textured | Good for classic, high-end products |

| Metalized | Smooth | Shiny finish for labels that stand out |

Vinyl labels have a little texture. This can change how clear your pictures look. It also lets you use different kinds of ink, even eco-friendly ones.

Stickers stick better to smooth things like glass and metal because the adhesive spreads out.

Rough things give stickers more grip, but you might need stronger adhesive.

Stickers for outdoor gear use mechanical adhesion to hold onto rough surfaces.

Think about where you will use the sticker and what you want it to do. For a fancy wine bottle, pick a textured label. For a shiny laptop sticker, use a smooth, glossy label.

Note: The right surface texture and sticker material help your stickers look good and last longer.

Matching Sticker Release Paper to Applications

Picking the right sticker paper is important. It helps your stickers look nice and last longer. You need to match sticker paper and release liners to what you want to do.

Permanent vs. Removable Stickers

First, think about if you want your stickers to stay or come off easily. Permanent sticker paper uses strong glue. It works well for bottles, boxes, and things that need labels to last. Removable sticker paper uses weaker glue. You can use it for wall decals, planners, or signs that you only need for a short time.

Here is a simple guide to help you choose sticker paper for your project:

| Factor | Description |

| Type of Vinyl | Pick glossy, matte, clear, colored, or textured sticker paper. |

| Application | Think about where you will use the sticker—inside, outside, flat, or curved surfaces. |

| Printer Compatibility | Make sure your sticker paper works with your printer type. |

| Adhesive Quality | Choose permanent or removable glue based on how long you want the sticker to stick. |

| Durability | Use sticker paper that does not tear or fade for tough jobs. |

| Size and Shape | Match the sticker paper size and shape to your design. |

| Price | Find sticker paper that fits your budget and needs. |

If you need waterproof stickers for outside, use sticker paper with a film liner and strong glue. For planners or notebooks, removable sticker paper lets you move stickers around.

Specialty Sticker Projects

Some projects need special sticker paper. High-tack glue works best for stickers that must stick to rough or hard surfaces. You need release paper that can handle strong glue, so stickers peel off easily and do not leave a mess. Low-tack glue is good for temporary projects. You can pick from more types of sticker paper because the glue is gentle.

High-tack glue needs tough release paper for easy peeling and no sticky mess.

Low-tack glue lets you use many kinds of sticker paper for quick changes or short-term stickers.

Always check the glue’s strength and make sure it matches your sticker paper and project.

Glossy sticker paper is good for bright, colorful stickers. Matte sticker paper works well for labels with lots of words. For special surfaces, like bumpy bottles or outdoor gear, use sticker paper that matches the surface.

Tip: Try your sticker paper before you start a big project. Print, cut, and stick a sample to see how it looks and feels.

Testing and Evaluation

Image Source: pexels

Step-by-Step Testing

You want your stickers to work well, so testing your release liner before a big project is smart. Here’s a simple way to check if your sticker release liner matches your adhesive:

Pick a few types of release liner you want to try.

Put a small amount of your adhesive on each release liner.

Let the adhesive dry as you would in your real project.

Peel the sticker off each release liner. Notice how easy or hard it is to remove.

Check if the adhesive stays on the sticker or if it leaves a mess on the release liner.

Look for any strange reactions, like sticky spots or color changes.

You want a release liner that lets you peel stickers off smoothly. The adhesive should stay on the sticker, not on the release liner. If you see any problems, try a different release liner before you print a lot of stickers.

Tip: Always test your release liner with your real adhesive and sticker material. This helps you avoid surprises later.

Comparing Sticker Release Paper Options

When you compare different release liner options, you want to look at a few key things. Each release liner has its own strengths. Use this table to help you decide:

| Criteria | What to Look For |

| Paper Thickness | Thicker release liner lasts longer. Thinner ones cost less but may tear easily. |

| Paper Finish | Matte release liner cuts glare. Glossy makes colors pop. |

| Adhesive Strength | Strong adhesive holds tight. Too strong can damage surfaces when you peel. |

| Compatibility | Make sure your release liner works with your printer and adhesive. |

| Cost | Compare prices, but think about quality and how long the release liner will last. |

You can also check how the release liner works in real life. Some industry tests put stickers on busy surfaces for a week. They see if the release liner keeps the sticker clean and easy to peel. These tests show that a good release liner can handle lots of use and even cleaning.

If you want the best results, try a few release liner types. See which one peels best, holds up to wear, and fits your budget. You will find the right release liner for your project by testing and comparing.

You can pick the best sticker release paper by following a few simple steps. First, choose the right paper material for your design. Next, double-check your sticker size so it matches your project. Always make sure you have a die-cut for easy printing. Here’s a quick checklist to help you:

Pick the correct paper material.

Confirm sticker dimensions.

Include a die-cut.

You’ve got this! With these tips, your stickers will look great and stick just the way you want.

FAQ

What is sticker release paper made of?

Sticker release paper uses a special layer. This layer stops stickers from sticking too soon. Most release paper has a smooth coating, like silicone. The smooth surface helps you peel stickers off easily. It does not rip or leave sticky marks.

Can I use any material for outdoor stickers?

You need the right material for outdoor stickers. Vinyl sticker material works best outside. It can handle rain and sunlight. This makes your stickers last longer in bad weather. Always pick a strong material for outdoor use.

How do I know if my sticker material is good quality?

Good sticker material feels strong and smooth. It should not tear when you touch it. The colors stay bright and do not fade. You can peel it off the release paper without problems. Good material also stands up to water and sun.

Why does my sticker not peel off easily?

Sometimes the release paper is too sticky or rough. Try using a smoother material next time. The right surface lets you peel off stickers easily. It should not rip or leave glue behind. Always test your material before making many stickers.

What is the best material for bright, colorful stickers?

Glossy material is best for bright colors. It makes your stickers look shiny and bold. Matte material is good for labels with lots of words. For art or photos, glossy material gives the best look.