Release paper silicone lets you pull off sticky things easily and fast. You see these coatings in food wrappers, medical tapes, and labels. More people want these products, so the market is growing:

The market for silicone coated release paper was $1.2 billion in 2024. It could reach $1.8 billion by 2033.

Release paper, including silicone types, might hit $5 billion by 2025.

Why do silicone release coatings work so well? Silicones have a special structure. This gives them low surface energy, strong heat resistance, and chemical stability. The table below lists the main science ideas:

| Principle | Description |

| Low Surface Energy | Stops things from sticking, so removal is easy. |

| Thermal Resistance | Handles very hot or cold temperatures without breaking. |

| Controllable Release Force | Can change to fit different stickiness needs. |

| Chemical Inertness | Safe for food and does not mix with other things. |

| Physical Barrier | Stops food and glue from touching the paper. |

| Durability | Stays strong after being used many times. |

Key Takeaways

Silicone release coatings help you peel off sticky things easily. They do not leave a mess behind. This is helpful for food packaging, medical tapes, and labels.

The market for silicone-coated release paper is growing fast. It may reach $1.8 billion by 2033. This shows more people want these products.

Silicone coatings have low surface energy. This stops adhesives from sticking too hard. It lets you remove labels and tapes cleanly.

You must pick the right silicone release coating for your project. Think about substrate compatibility, curing methods, and environmental impact.

New ideas in silicone coatings, like UV LED curing, make them better for the planet. These changes help cut down waste and save energy.

Release Paper Silicone Basics

What Is Release Paper Silicone?

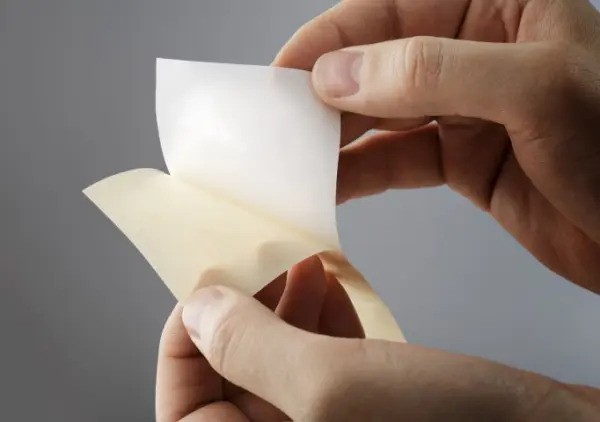

Release paper silicone is found in stickers, tapes, and food wrappers. This paper has a thin silicone layer on top. The silicone stops sticky things from sticking to the paper. You can peel off labels or adhesives easily because of this layer.

Release paper silicone comes in several types. The table below lists the main kinds and their features:

| Category | Description |

| Solvent based | Uses solvents for application. |

| Solvent free | Does not need solvents, often better for the environment. |

| Water-base emulsion | Uses water as a base, fits many uses. |

| UV curable | Cures under UV light, allows fast processing. |

Silicones give these coatings special qualities. They stop things from sticking and work in many ways. The surface is smooth and works well on paper and films. Many industries use it because adhesives do not stick until you want them to.

Why Use Silicone Release Coatings?

Silicone release coatings help you handle sticky things more easily. These coatings can stand high heat, so you can use them in hot jobs like printing or electronics. They also give great non-stick results, so there is less mess and waste.

Silicone release coatings let you peel labels and tapes without sticky leftovers.

You use them in hospitals for safe and clean removal of bandages and tapes.

They help in making clothes by protecting fabrics during heat transfer.

Silicone release coatings cost less over time and work better than other choices. You save money because they last longer and need fewer changes. Big industries like cars, electronics, and medical use these coatings for steady results.

Tip: If you need a coating that works in hard jobs and lets you remove things easily, pick silicone-based coatings. They give smooth surfaces and resist chemicals and heat very well.

Silicone Release Coatings Chemistry

Image Source: pexels

Silicones Structure and Properties

To know why release paper silicone works, look at its molecules. Silicones have a backbone made of silicon and oxygen atoms. This backbone is both bendy and tough. The main kind used is called polydimethylsiloxane (PDMS). PDMS has methyl groups attached to its backbone. These methyl groups make the surface smooth and slippery.

The methyl groups give silicones low surface energy. Water forms beads and rolls off the surface. Sticky things like glue do not stick well. This makes silicone-release coatings great for easy removal. You see these features in food wrappers and medical tapes.

Here is a table that shows the main features of silicones used in release coating:

| Property | Description |

| Key Component | Polydimethylsiloxane (PDMS) |

| Surface Tension | Low surface tension due to low intermolecular forces and high chain flexibility |

| Adhesion | Low adhesion and easy release from adhesives due to the flexibility of the PDMS backbone |

| Curing Process | Involves specific formulations that enhance the release properties of the silicone coatings |

| Interaction with Substrates | Forms a weak boundary layer preventing intimate contact and adhesive strength development |

Note: The methyl groups make silicones resist cold and water. They also stop glue from sticking. This gives you a surface that does not let water or glue stay.

Curing and Crosslinking

You must cure silicone release coatings to make them strong. Curing changes the liquid silicone into a solid layer. This happens when molecules join together in a network.

There are two main ways to cure silicone release coatings:

(Poly)addition method: You use silicone hydride and cure it with UV light or heat. This method is fast and helps production lines move quickly. You need an inert place because oxygen can slow the reaction.

(Poly)condensation method: You use special catalysts to speed up curing. This way is quick and cheap but can be hard to control. Sometimes the coating does not last long.

You can also pick between thermal curing and UV curing:

Thermal curing: You heat the coating to 120–180 °C. This uses a lot of energy and limits which papers or films you can use.

UV curing: You use ultraviolet light. This way is cleaner and works with more types of surfaces.

The curing method you choose changes how well the coating works. It affects how easy it is to peel off labels. It also changes how well the coating sticks to paper or film. Some ways use more energy, so you should think about the environment too.

Role of Catalysts

You need catalysts to help curing and crosslinking happen fast. Catalysts help molecules join together without making bad by-products. Platinum (II) complexes are the most common catalysts for silicone release coatings. These catalysts make the hydrosilation reaction go faster and smoother.

Platinum catalysts work well in addition-cured silicone systems. They do not make bad smells or waste. You often use Karstedt type platinum catalysts for thermal curing. You also add inhibitors to control how fast curing happens. This helps you get the right coating thickness and performance.

Tip: Always use the right catalyst and inhibitor for your silicone release coatings. This helps you get strong, reliable, and easy-to-peel surfaces.

Key Release Properties

Low Surface Energy

Have you ever wondered why sticky things do not stick to release paper silicone? The reason is its low surface energy. Silicone coatings have surface energy between 20 and 30 milliNewtons per meter (mN/m). This low number helps things peel off easily.

You can pull adhesives off the coating with little force.

Tapes and labels come off clean, with no sticky mess left behind.

The low energy surface lets you control how adhesives stick, so you can remove them when you want.

If you use labels or tapes, you know clean removal is important. Low surface energy gives you this clean release every time.

Tip: Pick coatings with low surface energy for easy removal and a neat finish.

Adhesion and Interfacial Energy

Adhesion and interfacial energy decide how well things stick or come off. Silicone release coatings use different forces. These include direct bonds, interpenetration, van der Waals forces, and mechanical dissipation.

Direct bonds and interpenetration help adhesives grip the coating.

Van der Waals forces are weak and can help or stop sticking.

Mechanical dissipation is important for release force. How an adhesive stretches and moves, called its Tan(Delta) value, changes how much force you need to peel it off.

Silicones have low friction. This makes them better release agents than fluorocarbons.

You can control these forces by picking the right coating. If you want easy peeling, choose coatings that balance these forces well.

Note: The right mix of adhesion and interfacial energy gives you the release you need.

Surface Topography

Surface topography means the shape and feel of the coating’s surface. This feature is important for how well your release coating works. The table below shows how surface topography affects performance:

| Key Findings | Description |

| Surface Structure | The shape and features of the surface change how silicone coatings work, including how they stick and release. |

| Crosslinking Effects | Good crosslinking stops group movement after curing, which helps with releasing. |

| Chain Density Impact | Too many soft silicone chains lower crosslink density, which can hurt release and leave more residue. |

When you use a coating with the right surface shape, you get better release and less sticking. Good crosslinking keeps the coating strong and stops unwanted movement after curing. If you add too many soft silicone chains, you lower crosslink density. This can make release worse and leave more residue.

Remember: How you design the surface of your release coating changes how well it works. Always check the topography for the best results.

Types of Silicone Coatings

Solvent-Based and Solventless Coatings

You can pick between solvent-based or solventless coatings for release paper silicone. Each type has good and bad sides. Solvent-based coatings have silicone polymers mixed in organic solvents. Solventless coatings use only reactive silicone polymers and do not need solvents. The table below shows how they are different:

| Feature | Solvent-Based Silicone Coatings | Solventless Silicone Coatings |

| Composition | Silicone polymers dissolved in organic solvents | 100% reactive silicone polymers with no solvents |

| Curing Process | Cured using heat, evaporating the solvent | Cured using thermal methods, UV light, or EB curing |

| Advantages | High performance, good wetting, versatile | Environmentally friendly, cost-effective, high efficiency |

| Disadvantages | Environmental concerns, regulatory issues, cost | Application challenges, limited substrate compatibility |

Solvent-based coatings are best if you want strong performance and good wetting. Solventless coatings are better for saving money and helping the environment. Both types can work well, but your choice depends on what you need.

When you choose a silicone release coating, think about these things:

These points help you pick the right coating for your job.

Emulsion Coatings

Emulsion coatings use water as the main carrier. These coatings are good if you want an eco-friendly choice. Emulsion coatings are safer to use and cost less. They also work with many kinds of paper and film. The table below lists their main pros and cons:

| Advantages | Disadvantages |

| Eco-Friendly & Low VOCs | Longer Drying & Curing Times |

| Safer to Handle | Potential for Uneven Coating |

| Cost-Effective | Lower Chemical & Heat Resistance |

| Compatible with Many Substrates | N/A |

You might pick emulsion coatings to help the environment. These coatings help you follow safety rules and save money. But you may have to wait longer for them to dry and they do not resist heat or chemicals as well.

When you pick a release coating, always think about how it works with your paper or film and how it cures. Emulsion silicones can give you safety and good results. If you need a coating for a special job, check the drying time and resistance before you choose.

Tip: Always match your release coating to your project’s needs. Think about the surface, the curing method, and how the coating will perform over time. This helps you get the best results from your silicone-release coatings.

Silicone-Coated Release Liner Paper Applications

Image Source: pexels

Industrial and Medical Uses

Silicone-coated release liner paper is used in many products. These liners cover sticky parts until you need them. In hospitals, they keep wound dressings clean and safe. You also find them in patches that give medicine through the skin. Surgical tapes and bandages use liners to keep adhesives fresh. The liners make it easy to put on medical labels in the right spot.

Here are some ways people use silicone-coated release liner paper in medicine and industry:

Wound care dressings

Electrodes for medical devices

Baby care products

Adhesive bandages

Medical tapes and bandages

Personal hygiene products

Wearable devices

Labels for medical equipment

These liners are also used in making products faster and better. Silicone release coatings stop adhesives from sticking too soon. This keeps products safe and simple to use.

Tip: Pick liners that protect adhesives and keep them clean for medical or industrial jobs.

Graphic Arts and Labels

People use silicone-coated release liner paper for graphic arts and labels. These liners let you peel off stickers and labels easily. They do not tear or leave sticky stuff behind. You can change how easy it is to peel off the label. Fast curing helps you make things quickly. These liners work with many kinds of paper and film.

The table below shows how silicone-coated release liner paper helps with graphic arts and labels:

| Feature | Benefit |

| Adjustable release force profiles | Lets you customize for different applications |

| Fast curing times | Speeds up production |

| Compatibility with various substrates | Works with many materials |

| Reliable label application | Keeps adhesives strong and labels in place |

| Low migration systems | Reduces contamination and improves adhesion |

| UV silicone technology | Cures at room temperature for heat-sensitive jobs |

Silicone-coated release liner paper helps your labels look neat and sharp. It stops problems like glue moving or labels not sticking well.

Note: If you work with labels or art, these liners give you the control and results you want.

Performance Factors

Formulation and Additives

You can make release liners work better by changing the mix and using the right additives. How you blend silicone with other chemicals affects how well the coating works. Additives help silicone stick to the paper. This makes the liner stronger and more dependable. Here are some key things to know:

Additives help silicone bond to paper, so the liner works better.

The amount of silicone and how it cross-links matter a lot for performance.

Some additives make strong covalent bonds. These last longer than hydrogen bonds and help the liner work with adhesives.

If you want liners to work with many adhesives, always check the mix and additives.

Substrate and Surface Prep

Good liners start with a clean substrate. You must get the surface ready before adding the coating. Here are some steps to follow:

Getting the surface ready helps you avoid problems like uneven coatings. If you skip these steps, the liner may not work well.

Process Variables

You need to control some process variables to get good liners. The table below shows the main ones and what they do:

| Process Variable | Impact on Quality and Consistency |

| Coating Thickness | Makes sure the coating is even, which helps the liner work right. |

| Curing Temperature | Changes the coating’s chemistry, which can help or hurt how adhesives release. |

| Line Speed | Decides how long the liner cures, which changes how easy it is to peel. |

| Tension Control | Keeps the liner flat and smooth, stopping problems that can mess up the release. |

Makers often have to keep tools clean, control dust, and watch humidity. You should also check for silicone transfer and make sure curing is done. For users, think about the adhesive type, heat, and how you will use the liner. Always pick the right liner for your job to get the best results.

Tip: Careful prep and process control help you get liners that work well with all adhesives.

Trends in Silicone Release Coatings

Quality and Testing

You want your release liners to work well every time. Quality checks help you get good results. Many companies now use EDXRF technology. This tool checks the silicone coat weight fast and saves money. It helps you find problems early and keep products the same. You should also look for silicone contamination. Many factories have control points to catch this. You can test water contact angles to see if the surface is ready for adhesives. These steps help you get the best release for pressure-sensitive adhesives. - Use EDXRF to check coat weight quickly. - Set up control points to stop contamination. - Measure water contact angles to check surface quality.

Tip: Good testing means fewer problems and better results for your customers.

Environmental Considerations

You care about the earth. New rules in the EU and North America want greener products. Companies now make coatings with low VOCs. These products help you follow rules and protect nature.

| Evidence | Description |

| Environmental Regulations | New rules want lower VOC emissions and greener products. |

| Demand for Sustainable Products | More people want eco-friendly silicone release agents. |

| Innovation in Product Development | Companies spend money to make coatings that meet green standards. |

You can help by recycling silicone release liners. This saves resources and makes less waste. If you recycle, you get back useful materials and use less energy. Liners that do not break down can fill landfills and add greenhouse gases. Pick coatings that help recycling and lower your impact on the planet.

Innovations

You see many new ideas in silicone release coatings. UV LED-cured technologies help you save energy and protect resources. Linerless solutions use less material and make less waste.

| Innovation | Description |

| UV LED-cured technologies | Efficient coatings that help the earth and save resources. |

| Linerless solution | New uses that cut down on material and waste. |

The UV-cure silicone release coating market is growing fast. Many industries, like electronics and packaging, use these coatings now. You can also use plasma treatment to help adhesives stick better. These changes help you get better results and meet new needs.

You can see how science helps silicone release coatings work well. The table below shows how different properties help in real life. Low surface tension means marine fouling organisms do not stick much. Low roughness makes it easy to remove these organisms. High flexibility helps the coating clean itself and release fouling. Cross-linking methods are needed for strong and lasting films. Tie-coatings help the coating stick better but still let fouling release.

If you know about chemistry and how coatings perform, you can pick better products. You can choose materials that last a long time. You can match coatings to what you need. You can make things better and save money.

New trends look at eco-friendly choices, smarter formulas, and digital tools. In the future, silicone release coatings will be even better and greener.

FAQ

What is silicone release paper used for?

Silicone release paper protects sticky things like labels and tapes. It also keeps medical bandages safe. You can peel off adhesives without mess. Products stay fresh until you use them.

Is silicone release paper safe for food contact?

You can use silicone release paper for food packaging. Makers build it to resist heat and chemicals. It does not mix with food or leave bad stuff behind.

How do you choose the right silicone release coating?

Think about what your project needs. Check the adhesive type and temperature. Look at the surface you will use. Pick a coating that fits your material and lets you peel easily.

Can you recycle silicone-coated release liners?

Some silicone-coated liners can be recycled. Many recycling places take them. Always check your local rules first. Recycling helps cut down waste and keeps nature safe.

Why does silicone release paper work better than wax paper?

Silicone release paper has lower surface energy than wax paper. This means peeling is easier and less sticky stuff stays. Silicone also stands up to heat and chemicals better, so it lasts longer.