You find PE coated paper trading in many businesses. It is used in packaging, food service, and hygiene items. This trading means buying and selling paper with a polyethylene layer. These papers are strong and keep out water. You see them in cups, food wraps, and medical packs.

The market for these items keeps getting bigger:

The PE coated paper cup market could be worth $2 billion by 2025.

Growth of 5–7% each year shows more people want eco-friendly choices.

More people want packaging that is better for the environment.

Knowing the types of products, market trends, and good suppliers helps you do well in this area. You also need to learn how global trade can change your business.

Key Takeaways

PE coated paper is very important for packaging, food service, and hygiene products. It stops water and grease from getting through. This makes it great for food and medical uses.

The PE coated paper market is growing fast. It may be worth $2 billion by 2025. More people want eco-friendly packaging. New recycling rules also help the market grow.

Picking the right supplier is very important. Choose companies with food safety certificates. Make sure they have a good reputation. This helps you get good and reliable products.

Learn about international trade rules. Knowing about tariffs and regulations can help you with importing and exporting PE coated paper.

Think about sustainability. Using recyclable materials and eco-friendly ways can make your business look better. It also meets what customers want for greener choices.

PE Coated Paper Overview

Definition

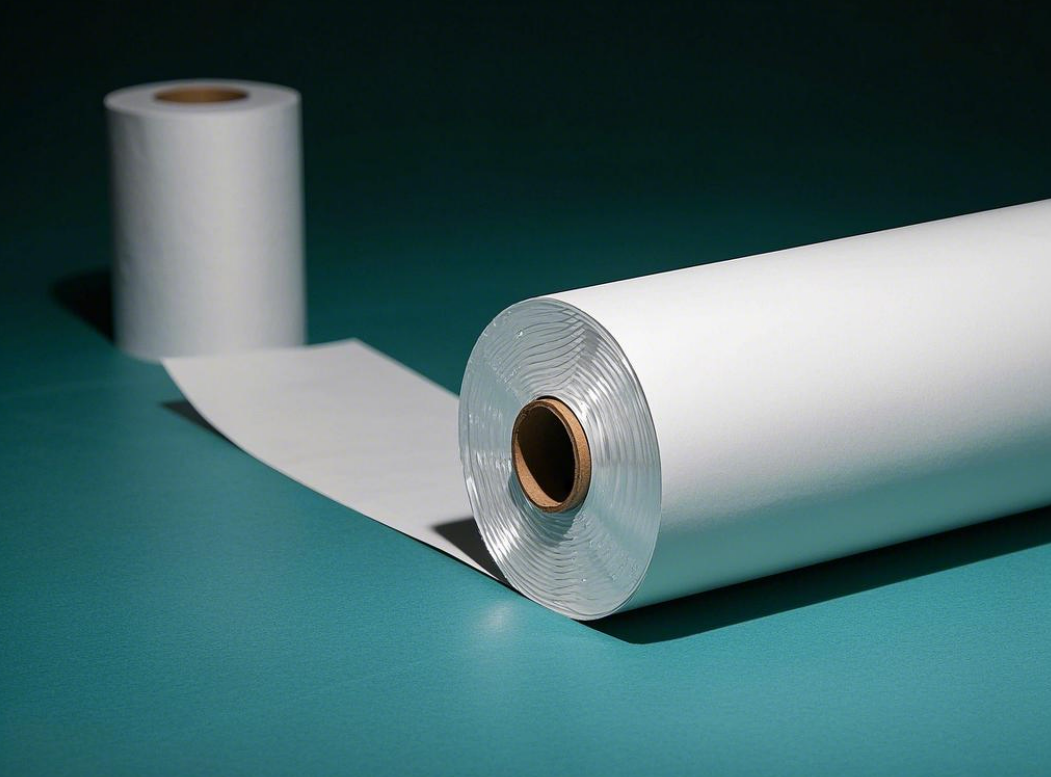

PE coated paper is used in many businesses. It has a thin PE layer on the paper. This layer keeps out water and oil. It also blocks other liquids. You see PE coated paper in food and drink packaging. It is also used for medical items. The PE coating makes the paper stronger. It lasts longer and does not tear easily. Many places can recycle PE coated paper. This helps the environment. Some companies use special coatings. These coatings break down faster and are better for nature.

Types and Grades

There are many kinds of PE coated paper. You pick the type you need. MG paper is shiny and good for printing. It looks nice on packages. MF paper is smooth and works for labels. It is also used for wraps. You can choose virgin or recycled paper. Virgin paper uses new wood pulp. Recycled paper uses old fibers. The paper can be thick or thin. It ranges from 30 to 120 grams. You match the thickness to your needs. Cupstock board is used for cups and plates.

| Product Type | Description |

| Application | Packaging, Labels, Food Service, Construction, Medical |

| Material Type | High-Density Polyethylene, Low-Density Polyethylene, Biodegradable Polymer, Recyclable Polymer |

| End Use | Food & Beverage, Consumer Goods, Electronics, Healthcare, Manufacturing |

| Coating Type | Single-Sided, Double-Sided, Waterproof, Bamboo Coating |

| Regional Outlook | North America, Europe, South America, Asia Pacific, Middle East and Africa |

Applications

You find PE coated paper in many places. In food and drinks, it is used for cups and plates. It is also used for takeout boxes. In hospitals, it wraps medical tools. It also packs medicine. Stores use it for waterproof bags and labels. It is used for brochures too. The PE coating keeps out water. It stops leaks and spills. These products last longer. Many PE coated papers can be recycled. This helps cut down on trash.

| Industry | Applications |

| Food and Beverage | Disposable cups and plates, cold beverage containers, fast food packaging, takeout containers |

| Medical | Protective wrapping for medical devices, packaging for pharmaceuticals and surgical instruments |

| Retail and Consumer Goods | Waterproof shopping bags, durable labels and stickers, high-quality brochures and magazines |

PE coated paper keeps out water and grease.

The barrier keeps food fresh.

You can recycle PE coated paper after using it.

PE Coated Paper Market

Market Size

The pe coated paper market gets bigger every year. More companies use pe coated paper for packaging. The market value goes up as demand grows. Experts think the market will be worth billions soon. The CAGR is expected to be about 4-5% in five years. This means the market will keep growing. Many industries want pe coated paper because it blocks moisture and grease. You see it in food packaging, medical wraps, and retail items. New rules about recycling and being green affect the market. More companies want recyclable and eco-friendly choices. There is also a move toward coatings that break down faster.

| Year | Market Value (USD) | CAGR (%) | Recycling Rate (%) |

| 2022 | $1.6 Billion | 4-5 | 35 |

| 2025 | $2 Billion | 4-5 | 40 |

Tip: You can find good investment chances in the pe coated paper market. Watch for new trends and focus on recyclable products.

Key Regions

The pe coated paper market is busy in many places. North America and Europe use and make the most pe coated paper. These areas have strong industries and care about packaging quality. Many companies there use pe coated paper for food and retail. Asia-Pacific is growing the fastest in this market. More factories and higher incomes help the market grow. China and India are big players. More businesses use pe coated paper for food, drinks, and online shopping. The market in Asia-Pacific keeps getting bigger as more people buy packaged goods.

North America: Lots of pe coated paper used for food and retail.

Europe: High recycling rates and cares about green packaging.

Asia-Pacific: Fastest growth, led by China and India, with more food and online shopping.

Demand Drivers

Many things help the pe coated paper market grow. People care more about the planet now. They pick pe coated paper because it can be recycled and stops leaks. New laws limit plastic, so companies use pe coated paper instead. Better technology makes pe coated paper stronger and last longer. Businesses want packaging that looks nice and protects things. More online shopping means more packages need pe coated paper.

People want packaging that is good for the planet

Tough rules against plastic packaging

New ways to make pe coated paper better

Packaging can be made in many styles

Online shopping is growing fast

Food, healthcare, and personal care need green packaging

Note: Your business can grow by picking pe coated paper that is strong and can be recycled. Try new packaging ideas and follow market changes.

Suppliers

Leading Companies

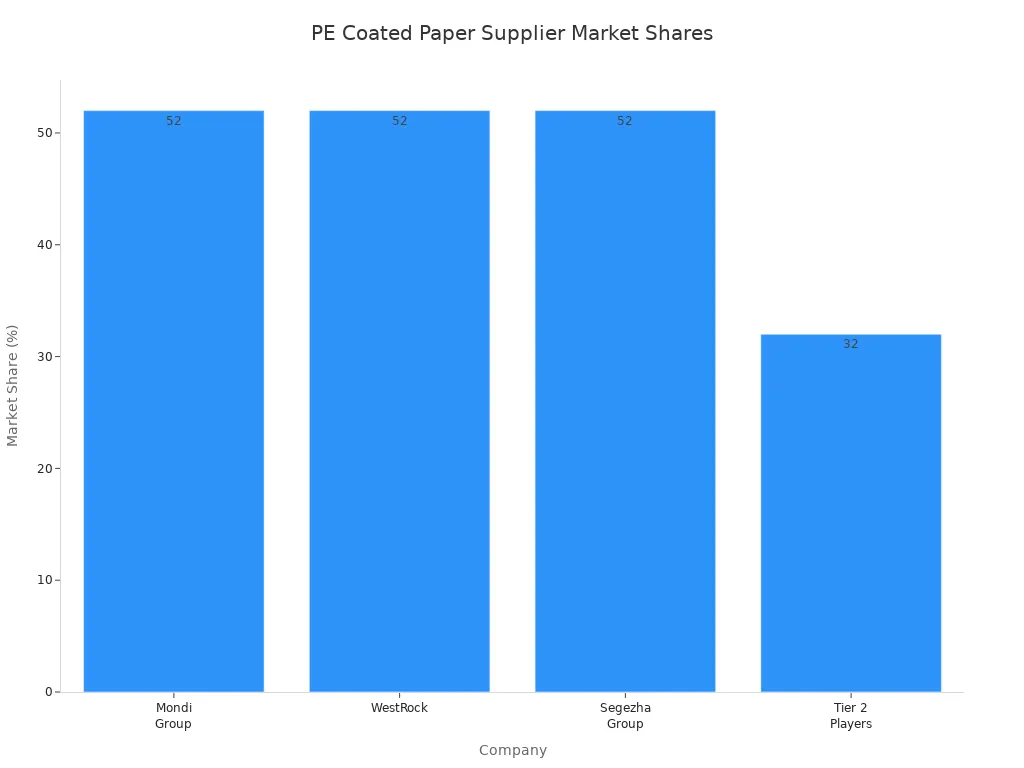

If you want pe coated paper, you should know the top companies. Many businesses sell good coated paper for packaging and printing. WESHARE, SUNRISE PAPER CO., LTD, and Spectra Paper Plast are experts in pe coated paper. These companies care about quality and making strong paper. Their products keep out water and last a long time. They help you pick pe coated paper that is tough and keeps things dry.

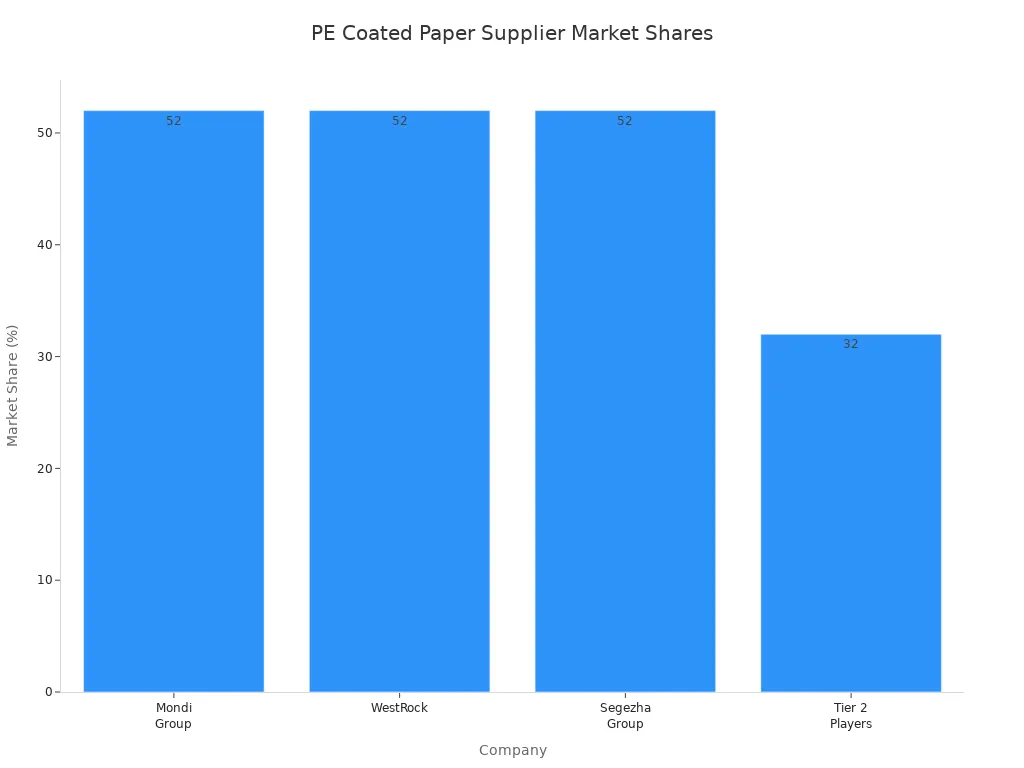

Big companies like Mondi Group, WestRock, and Segezha Group are leaders too. They have a big part of the pe coated paper market. Their paper is strong and blocks water well. The table below shows how much of the market the top 10 suppliers have:

| Company | Market Share Contribution |

| Mondi Group | 52% |

| WestRock | 52% |

| Segezha Group | 52% |

| Tier 2 Players (Canfor, Nordic Paper, Gascogne Group) | 32% |

Tip: Picking from the top 10 pe coated paper suppliers means you get better paper and service.

Sourcing Strategies

You want good pe coated paper for a fair price. Try these steps to help you:

Check if the supplier follows food safety rules like FDA or EU.

Look for green certifications such as FSC.

See if the supplier can make enough paper for you.

Ask about recycled materials and energy use.

Compare prices, but also think about quality and service.

Read reviews and ask others about the supplier.

Work with your supplier for a long time. Talking often helps you deal with changes.

Here are some ways to find the best pe coated paper:

| Strategy | Description | Benefits | Challenges |

| Establish Clear Specifications | Say what kind of paper you need. | Makes sure you get the same good paper each time. | You need to know a lot about pe coated paper. |

| Build Relationships with Suppliers | Work together and help each other grow. | You get better deals and a stronger supply chain. | It takes time to trust each other. |

| Leverage Technology | Use computers and online tools to buy paper. | You can buy faster and easier. | You need to spend money on new tools. |

| Conduct Regular Audits | Check how your supplier works often. | Keeps the paper good and the company honest. | It can slow down normal work. |

| Diversify Supplier Base | Buy from more than one supplier. | You lower risk and can get better prices. | It is harder to manage many suppliers. |

Note: If you focus on quality and strong paper, your supply chain gets better. Using smart sourcing helps you get the best pe coated paper for your business.

Trade

Image Source: unsplash

International Flows

You see PE coated paper moving across borders every day. Many countries export large amounts of this product. Germany, Sweden, and the United States send PE coated paper to many regions. Asia Pacific and Latin America buy most of these exports. Europe sends more PE coated paper to Asia Pacific each year. The trade between these regions grew by 12% recently. You can check the main trade flows in the table below:

| Exporting Countries | Importing Regions |

| Germany | Asia Pacific |

| Sweden | Latin America |

| United States |

|

Tip: You can find new business chances by watching trade flows between Europe and Asia Pacific.

Regulations

You must follow strict rules when you trade PE coated paper. Each country sets its own standards for packaging and safety. You need to check if your products meet food safety laws like FDA in the United States or EFSA in Europe. Some countries ask for special labels or certificates. You should learn about customs rules before you ship your goods. If you follow all the rules, you avoid delays and fines.

Tariffs

You pay tariffs when you import or export PE coated paper. These duties change from country to country. Some regions set high tariffs to protect local businesses. Others lower tariffs to help trade grow. You need to check the latest tariff rates before you make deals. Tariffs can affect your profit and your price in the market. You can ask your supplier or customs agent for help with tariff codes.

Logistics

You face many challenges when you ship PE coated paper around the world. Freight costs change often and make pricing hard. Port congestion and shipping delays can slow down your deliveries. Higher shipping costs can make your products less competitive. You need to plan your shipments and watch for changes in the market.

Freight costs change quickly and affect your prices.

Port congestion and delays can slow down your orders.

High shipping costs can make it hard to compete with local suppliers.

Note: You can lower risks by working with trusted logistics partners and planning ahead for delays.

Food Safety and Hygiene

Standards

You must make sure your PE coated paper follows food safety rules. These rules help keep people safe when they use products for eating and drinking. The FDA in the United States has rules for materials that touch food. In Europe, you need to follow EU laws. These rules check if the materials are safe. They also set limits for how much can move from the paper to food. You need to test your paper to make sure it is safe. The table below lists some important rules you should know:

| Regulation Type | Regulation Number | Description |

| FDA Regulations | 21 CFR 177.1520 | Polyethylene specifications |

| FDA Regulations | 21 CFR 176.170 | Components for paper in food contact |

| FDA Regulations | FCN | Food Contact Notification requirements |

| FDA Regulations | Migration testing | Migration testing protocols |

| EU Regulations | EC No 1935/2004 | Materials in contact with food |

| EU Regulations | EU No 10/2011 | Plastic materials in food contact |

| EU Regulations | EFSA | Safety assessments and opinions |

| EU Regulations | Migration limits | Migration limits and testing methodologies |

You want your packaging to be approved by the FDA. It should not have any harmful chemicals. This keeps food safe for everyone. PE coated paper must pass tests to make sure chemicals do not move into food.

Industry Uses

PE coated paper is used in many kinds of packaging. Fast food wrappers use it to keep burgers and sandwiches fresh. Bakeries wrap bread and pastries to stop grease and water from leaking. Beverage cups use PE coated paper so drinks do not leak. Frozen foods stay safe from freezer burn because of this coating. Hospitals use PE coated paper for medicine and tools. It keeps them clean and safe.

| Application Type | Specific Uses |

| Fast Food Wrappers | Wrapping burgers, sandwiches, preventing grease and moisture seepage |

| Bakery Products | Packaging bread, pastries, maintaining freshness |

| Frozen Foods | Protection against freezer burn and moisture |

| Beverage Cups | Leak-proof containers for hot and cold drinks |

| Medical Packaging | Sterile packaging for instruments and pharmaceuticals |

Tip: Always make sure your packaging follows food safety rules before you use it for food or medicine.

Trends and Opportunities

Market Trends

The pe coated paper market is changing fast. Online shopping is getting bigger every year. Strong packaging is needed for shipping products safely. Pe coated paper helps protect things during delivery. Governments want companies to use packaging that is better for the planet. These rules help the market grow. Food companies use pe coated paper to keep food fresh. More businesses pick new ways to package their products. Technology makes pe coated paper better and faster to make. The market could be worth $5.86 billion in 2024.

Online shopping needs tough packaging.

New laws help eco-friendly packaging grow.

Food companies use pe coated paper to keep food fresh.

Technology makes pe coated paper stronger.

People want packaging that is good for the planet.

Tip: Watch for new trends in pe coated paper. You can find business ideas by following changes in technology and what customers want.

Sustainability

You help make packaging better for the earth. The pe coated paper market cares about being green and new ideas. Companies use materials that can be recycled to cut waste. PE coated boards help make recycling easier. They replace old products that do not break down. The paper industry has worked on recycling for over 30 years. More money goes into recycling and green ways of working. Businesses compare PE coated boards to older materials. They pick them because they are better for the planet.

Being green helps cut waste and pollution.

Recycled packaging helps the planet.

Companies spend money on recycling and green tools.

Eco-friendly ways help your business stand out.

Note: You can help the earth by picking green packaging and joining recycling programs.

Future Outlook

The pe coated paper market will grow more in the next ten years. Experts think it will grow by 4.5% each year from 2025 to 2033. The market could reach $15.8 billion by 2033. More people want packaging that is green and can be recycled. This is true for food and drinks. New coatings make products safer and stronger. Asia Pacific and Latin America will grow the fastest. Computers and research help companies make better packaging. Online shopping will keep needing strong packaging.

| Year | Market Size (USD) | CAGR (%) |

| 2025 | $5.86 Billion | 4.5 |

| 2033 | $15.8 Billion | 4.5 |

The pe coated paper market will keep getting bigger.

Technology and being green will shape the future.

You can find new chances by watching the market.

Tip: Keep learning about green ways and new ideas. You can grow your business by using smart packaging and eco-friendly ways.

PE Coated Paper Trading Tips

Negotiation

Good negotiation skills help you do well in pe coated paper trading. The market changes fast, so you need to be ready to adjust. You can use non-offer offers to set a starting price. This lets you keep your choices open and stay flexible. Range offers are helpful too. You can give a price range instead of one number. This shows you are willing to work with others and can help you get better deals.

Use non-offer offers to set a starting price and keep choices open.

Give a price range to show you are flexible and get better deals.

Listen to what your supplier wants and change your plan if needed.

Ask for samples before you buy a lot.

Talk about payment terms that help you manage your money.

Try to build long-term relationships for better prices and service.

Tip: You can do better in the pe coated paper market by being flexible and building trust with suppliers.

Quality Assurance

Quality is very important in pe coated paper trading. You need to check every step to make sure you get good coated paper. The market wants high standards for packaging, labeling, printing, and food safety. You should look at raw materials, watch the process, and test finished products. The table below shows important steps for quality control:

| Quality Control Process | Description |

| Raw Material Inspection | Check paper base, test pe resin, and look at additives |

| Process Control Measures | Watch extrusion temperature, measure coating weight, check adhesion |

| Finished Product Inspection | Look at surface, check size, and test stability |

You also need to test for water resistance, grease resistance, and tensile strength. These tests help you meet market needs and make sure your packaging works well.

| Test Type | Procedure | Acceptance Criteria |

| Water Resistance | Put samples in water for a set time | No leaks, little softening |

| Grease Resistance | Put oils on samples at set temperatures | No stains or leaks |

| Tensile Strength | Pull samples with force | Meets minimum strength needed |

You should follow FDA rules for food safety. ASTM standards like D6868 and F119-82 help you check compostability and steam resistance. European rules like EU 10/2011 and EFSA guidelines set limits for pe coated paper. These steps keep your business and customers safe.

Check every shipment for problems.

Ask for certificates for food safety and compostability.

Test samples before you get the full order.

Watch quality trends in the pe coated paper market.

Note: You can build a good name in pe coated paper trading by focusing on quality and safety.

Risk Management

There are many risks in pe coated paper trading. The market can change quickly, so you need to be ready for supply chain issues and money problems. You can lower risks by planning ahead and working with trusted partners. The table below lists important risk management steps:

| Risk Management Practice | Description |

| Develop Contingency Plans | Make plans for risks, list key contacts, and find backup suppliers |

| Seek Insurance and Financial Safeguards | Use supply chain insurance and trade credit insurance to protect your business |

| Treat Suppliers as Business Partners | Build strong relationships for better service and communication |

| Invest in Technology and Automation | Use blockchain, AI, and IoT to track shipments and control the supply chain |

| Diversify Supplier Base | Work with more suppliers to avoid problems if one cannot deliver |

You should always watch for changes in the pe coated paper market. You can use technology to track shipments and find problems early. Insurance helps you recover from losses and keep your business going. Treat your suppliers as partners, not just sellers. This helps you get better service when things get tough.

Check your risk plans every year.

Use digital tools to track orders and shipments.

Build strong relationships with suppliers in the pe coated paper market.

Work with more suppliers for better prices and reliability.

Tip: You can keep your business safe in pe coated paper trading by planning for risks and using smart tools.

You now know the basics of PE coated paper trading. This includes how the market is growing, how to pick suppliers, and how trade works around the world. You can use market trends and being green to help your business grow. Many traders do well by making special packaging and using eco-friendly materials. You can get ahead by making strong partnerships and trying new technology.

Actionable steps for success:

Get feedstock from your own country to save money.

Use online tools to order faster and work smarter.

Give design, printing, and green certifications.

Spend money on recycled paper and better coatings.

Buy resin from different suppliers and join recycling groups.

Make labels easy to read and check how products affect the planet.

You can be different by using these steps and changing when the market changes.

FAQ

What is PE coated paper?

PE coated paper has a thin layer of polyethylene. This layer makes the paper strong and keeps out water and oil. You see it in food packaging, cups, and medical wraps.

Can you recycle PE coated paper?

You can recycle some PE coated paper. Many recycling centers accept it. You should check local rules before you recycle. Some coatings break down faster and help the environment.

How do you choose a good supplier?

You look for suppliers with food safety certificates. You check reviews and ask for samples. You compare prices and quality. You build trust by talking often and asking questions.

Why do companies use PE coated paper for food packaging?

PE coated paper keeps food fresh and safe. It blocks water, grease, and oil. You see it in cups, wrappers, and boxes. It helps food last longer and look better.

What tests check the quality of PE coated paper?

You test for water resistance, grease resistance, and strength. You use simple lab tests. You ask for certificates from suppliers. These tests help you get safe and strong packaging.