You see top greaseproof paper manufacturers like Ahlstrom-Munksjö and Nordic Paper lead the field.

The world market for greaseproof paper is about $988 million in 2024.

Ahlstrom-Munksjö has 20% of the market.

Nordic Paper has 15% of the market.

Greaseproof paper is important for food and packaging. Many companies choose greaseproof paper from these manufacturers because it helps with plastic waste problems. Greaseproof paper comes from sources that can be replaced, supporting eco-friendly plans. Greaseproof paper keeps food safe and packaging clean.

Key Takeaways

Leading greaseproof paper makers like Ahlstrom-Munksjö and Nordic Paper are important. They offer eco-friendly choices that help cut down on plastic waste.

Greaseproof paper is needed for food safety. It keeps food fresh and clean. It also stops grease and moisture from getting through.

New ways to make greaseproof paper use nanotechnology and bio-based coatings. These methods make the paper stronger and better for the environment.

Certifications like FSSC22000 show that greaseproof paper is safe and high quality for food packaging.

The industry is moving toward PFAS-free and biodegradable options. This helps people pick eco-friendly packaging more easily.

Greaseproof Paper Manufacturers

Industry Leaders

Some greaseproof paper manufacturers are very important worldwide. These companies change how people use greaseproof paper for food and packaging. The most well-known greaseproof paper manufacturers are:

Ahlstrom-Munksjö

Nordic Paper

Mondi Group

Delfort Group

SCG Packaging

These companies have a big part of the greaseproof paper market. You can look at their market shares in this table:

| Company | Market Share | Annual Production (metric tons) |

| Ahlstrom-Munksjö | 17% | 330,000 |

| Nordic Paper | 25% | N/A |

| Delfort Group | 20% | N/A |

| Metsä Tissue | 13% | 250,000 |

The top three greaseproof paper makers together have about 20% of the world market. These companies make a lot of paper every year. They give greaseproof paper to many businesses, especially those that pack food.

These manufacturers work in many places. North America uses a lot of greaseproof paper because it has many food and drink companies. Europe wants packaging that is good for the planet, so greaseproof paper makers grow there. Asia-Pacific is the fastest-growing place for greaseproof paper. Smaller markets are also growing in Latin America, the Middle East, and Africa.

What Sets Them Apart

You may ask why these greaseproof paper makers are special. They use new technology and sell paper all over the world. Top greaseproof paper manufacturers use new coatings to make their paper block grease and water better. These coatings help keep food safe and dry.

These companies also use machines to make paper faster and better. Some use nanocoatings and bio-based coatings. These new ideas make the paper even stronger and help the environment.

Tip: If you pick greaseproof paper from top companies, your food stays safe and you help the planet by making less trash.

Greaseproof paper makers also help with printing and branding. They make special designs for packaging so products look different. These companies follow strict rules for food safety and packaging. They can make more paper when people need it.

Big supply chains help these companies send greaseproof paper everywhere. Local hubs in Indonesia, Thailand, and Vietnam help them reach nearby markets. This lowers costs and helps food sellers get the paper they need.

Greaseproof paper makers use strong barrier technology, local hubs, and good supply chains. This makes them top leaders in packaging. You get quality, safety, and care for the planet every time you use greaseproof paper.

Greaseproof Paper Uses

Image Source: pexels

Food Applications

Greaseproof paper is used a lot in food. People use it to wrap bakery goods and line trays. It helps keep food fresh. Greaseproof paper stops oil and water from getting through. This keeps food safe and clean. Most greaseproof paper is made for food. You see it in:

Food packaging

Bakery products

Confectionery

Takeaway and fast food

Food service industry

Greaseproof paper helps food stay fresh and stops leaks. The food industry uses the most greaseproof paper. Bakeries, sandwich shops, and fast food places use it often. People wrap sandwiches, pastries, and candies with it. Greaseproof paper stops food from sticking. It also makes cleaning up easier.

Did you know? The greaseproof paper market for food packaging was USD 1.2 billion in 2024. It may reach USD 2.3 billion by 2035. This shows people use greaseproof paper more for clean and grease-free wraps.

People pick greaseproof paper because it works well. They want packaging that keeps food safe and helps the planet. Many people care about the environment. They look for eco-friendly labels on greaseproof paper. Still, they want packaging that is good and easy to use.

Other Industries

Greaseproof paper is used outside food too. Many industries need paper that blocks grease and water. You find greaseproof paper in cosmetics, medicine, and industrial packaging. It wraps soaps, lines boxes, and protects special items.

Here is a table that shows how industries use greaseproof paper:

| Industry | Greaseproof Paper Use |

| Cosmetics | Wrapping soaps and creams |

| Pharmaceuticals | Barrier for pills and powders |

| Industrial | Packaging for machine parts |

| Retail | Gift wrapping and specialty boxes |

Stores use greaseproof paper for wrapping gifts. People use it to keep things safe when shipping. Greaseproof paper blocks oil and water. It protects items well. People trust greaseproof paper because it is strong and useful.

Greaseproof paper helps many industries with packaging. People choose it for its barrier and eco-friendly choices. Greaseproof paper helps businesses give good products.

Production Processes

Pulping and Preparation

Making greaseproof paper starts with picking the right materials. Manufacturers often use softwood or recycled paper. The pulp’s quality changes how well the paper blocks grease. Here are the main steps in pulping and preparation:

Raw Material Selection: Softwood or recycled paper is chosen for strong fibers.

Debarking and Chipping: Workers take off bark and cut logs into chips.

Pulping: Machines break up fibers with chemicals or force.

Pulp Washing and Screening: The pulp gets washed to clean out chemicals.

Bleaching (Optional): Some companies bleach the pulp to make it whiter.

Beating and Refining: The pulp is beaten to make fibers stronger.

Greaseproof Treatment: Beating and chemical sizing add greaseproof properties.

Forming the Paper Sheet: The pulp spreads out on a Fourdrinier machine.

Calendering: The paper is pressed and smoothed for an even surface.

Reeling and Cutting: The paper rolls up and is cut to the right size.

Quality Control and Testing: The paper is tested for greaseproof strength.

Tip: Good pulp and careful refining make smooth, strong greaseproof paper.

The choice of materials and how they are processed is important. Manufacturers compress the pulp to make it less porous. This helps the paper block grease better. Surface treatments with alginate, CMC, or starch add more resistance to oil and water. These steps help the paper meet industry needs.

| Step | Description |

| Raw Material Preparation | Pulp from wood or natural fibers is refined for smooth texture. |

| High-Density Processing | Pulp is pressed to lower porosity and boost grease resistance. |

| Surface Treatment | Coated with alginate, CMC, or starch for more resistance to oils and moisture. |

Greaseproofing Techniques

Special techniques give paper its greaseproof properties. The greaseproof paper industry uses different methods to make the barrier stronger. Here is a table showing common greaseproofing techniques and what they do:

| Greaseproofing Technique | Performance Impact |

| Silicone Coatings | Keeps paper non-stick and eco-friendly. |

| Fluorochemical-free Solutions | Works well and is safe for the environment. |

| Enhanced Surface Treatments | Makes paper resist grease and last longer with new technologies. |

| Plasma Treatment | Raises surface energy and improves grease resistance. |

| Electrospinning | Adds a microfiber layer for more durability and even coating. |

| Use of FSC-certified Paper | Lowers environmental impact compared to plastic. |

Silicone coatings help paper stay non-stick and eco-friendly. Fluorochemical-free solutions work well and are safe for the planet. New greaseproof paper technologies like plasma treatment and electrospinning make the barrier stronger. Using FSC-certified paper helps the environment, which matters for the industry.

Note: Better surface treatments and new techniques make greaseproof paper stronger for food and packaging.

Coating and Finishing

Coatings and advanced greaseproof paper technologies finish the paper. These steps make the paper block grease better and last longer. Manufacturers use nanotechnology for thin, water-based coatings. These coatings keep the paper looking natural and make it tougher.

Better surface treatments are big changes in the greaseproof paper industry. You get stronger grease resistance and longer-lasting paper.

Plasma treatment boosts the surface energy, making the barrier much stronger.

Electrospinning adds microfibre coatings for more durability and even coverage.

Nanotechnology lets you add thin coatings that keep the paper’s texture but make it more greaseproof.

The paper gets a precise coating thickness, so every sheet works the same. These finishing steps help greaseproof paper work for food wraps and industrial packaging.

Tip: Advanced greaseproof paper technologies make packaging safer, cleaner, and better for the planet.

Coating and finishing are important steps in making greaseproof paper. They help the paper block grease and stay strong. The greaseproof paper industry keeps improving these steps to meet new needs and help the environment.

Quality Standards for Food

Certifications

You want to be sure greaseproof paper is safe for food. Top companies follow rules like FSSC22000 and Nordic Swan Ecolabel. These rules show the paper is safe and high quality. You see these labels on packages. They mean the paper is made with care for health and nature.

Here is a table that shows what these certifications need:

| Requirement | Description |

| Energy Efficiency | Factories must use energy well and avoid fossil fuels. |

| Chemical Properties | Chemicals must be safe for people and the planet. |

| Fiber Traceability | At least 70% of fibers must be from certified forests and tracked. |

| Emission Limits | Factories must keep air and water pollution low. |

These rules help keep food and the earth safe. Companies must follow laws like European Regulation (EC) No. 1935/2004, BfR XXXVI, and ISO 9001:2015. These laws make sure greaseproof paper does not put bad stuff in food. You see BRC Certification on packages. This means the paper is safe by law.

Tip: Always look for certifications when you pick greaseproof paper for food. Certified paper helps you feel safe about what you use.

Testing Methods

You want greaseproof paper that keeps food clean and safe. Companies test greaseproof paper for grease resistance and safety. They use tests like the Kit Test (TAPPI T559), Turpentine Test (TAPPI T454), and Permeability Test (ISO 16532-1). These tests check how well the paper blocks grease, oil, and wax.

Here is a table that explains common testing methods:

| Testing Method | Purpose | Procedure | Applications |

| Grease Resistance Test (TAPPI T559) | Checks if paper stops oils and grease | Put solutions on paper and see if they go through | Used for food wrappers |

| Oil Repellency Test (AATCC 118) | Checks how well paper stops oil | Drop oil on paper and rate how it works | Used for textiles and paper |

| Gravimetric Analysis | Measures how much oil paper takes in | Weigh paper before and after oil | Used for absorbent paper |

| Contact Angle Measurement | Checks how oil sits on paper | Measure angle of oil drop on paper | Used for coatings on paper |

Companies also use ASTM tests to check for safety. They look for heavy metals, solvents, and other bad things. Labs test paper often and keep records for each batch. You get greaseproof paper that meets food safety rules because companies work hard to keep quality high.

Note: Keeping quality the same is important. Companies face problems like high costs and changing needs. They use strong quality checks and watch their work to meet rules and keep buyers happy.

Greaseproof Paper Industry Trends

Sustainability

Sustainability is changing how greaseproof paper is made and used. Many companies now pick PFAS-free greaseproof paper to keep people and nature safe. More people want eco-friendly packaging, so this kind of paper is getting popular. Manufacturers use bio-based coatings and recycled paper stock. This makes greaseproof paper safer for food and better for the earth. Some use plant-based wax coatings that block grease and water but are still good for the environment.

PFAS-free greaseproof paper helps you stay away from bad chemicals.

Carccu makes renewable, PFAS-free greaseproof paper for food packaging.

These papers keep food safe and block grease without using fluorochemicals.

They break down in compost and help protect nature.

Asia Pacific is growing fast in PFAS-free food packaging because of strict rules in Japan, South Korea, and Australia.

Companies use eco-friendly printing inks to help the planet. They use less water and more renewable energy to make greaseproof paper. You can find recycled paper stock and bio-based coatings in many products. These steps help cut down waste and lower carbon footprint. Biodegradable packaging and compostable solutions are getting more popular. Manufacturers spend money on research to make packaging and printing better for the earth. They use custom-printed greaseproof paper for branding and marketing to show they care about the planet.

Tip: You help the earth when you pick greaseproof paper made from recycled paper stock and sustainable materials.

Eco-friendly greaseproof paper breaks down fast and does not leave bad stuff behind. Old-style greaseproof paper can pollute and takes a long time to break down. You see the difference when you choose packaging that is better for the earth.

Innovations

Innovation is moving the greaseproof paper industry forward. New technology makes greaseproof paper stronger and better for the planet. Manufacturers use digital tools and machines to make printing and production better. Some use new silicone coatings that need less silicone but still do not stick. Fluorochemical-free solutions give strong protection without bad chemicals.

| Innovation Type | Description |

| Silicone Coating Innovations | Uses less silicone, works better, keeps non-stick. |

| Fluorochemical-Free Solutions | Grease resistance with safe, new coatings. |

| Enhanced Surface Treatments | Nanotechnology makes thin coatings for better barrier and strength. |

| Sustainable Materials | Papers made from recycled and bio-based materials, which are better for the earth. |

You see new surface treatments using nanotechnology. These make greaseproof paper last longer and block grease better. Using recycled paper stock and bio-based coatings helps protect the planet. Manufacturers use machines and digital printing to make custom-printed greaseproof paper. These new ideas make printing faster and more exact.

Manufacturers work with food companies and packaging partners to make new greaseproof paper products. They spend money on research to make packaging and printing better for the earth. Working together helps them reach more people and come up with new ideas. Companies set clear goals for helping the planet and tell you about their progress through branding and marketing. You get greaseproof paper that is safe, good for the earth, and looks great.

Top greaseproof paper manufacturers do well because they use new methods and follow strict rules.

They spend money on research to make greaseproof paper better and stronger for food packaging.

These companies pick good fibers and test the paper in clean rooms. They watch the temperature and humidity closely.

| Benefit | Description |

| Food Safety | Greaseproof paperboard has FDA approval, so it is safe for food. |

| Contamination Reduction | Greaseproof paper makes a strong wall, so less bad stuff can get in. |

Greaseproof paper keeps food fresh and safe, so people trust it. You will see more eco-friendly choices, stronger barriers, and special printing for food packaging. The greaseproof paper industry will keep making new things for a cleaner world.

FAQ

What makes greaseproof paper different from regular paper?

Greaseproof paper stops oil and water. Regular paper soaks up grease and gets stains. Special coatings make greaseproof paper strong. It is safe for food.

Can you recycle greaseproof paper?

Some greaseproof paper can be recycled. It depends on coatings and food left on it. Always check your local recycling rules. Many companies use eco-friendly materials now. This helps you recycle easier.

Is greaseproof paper safe for baking?

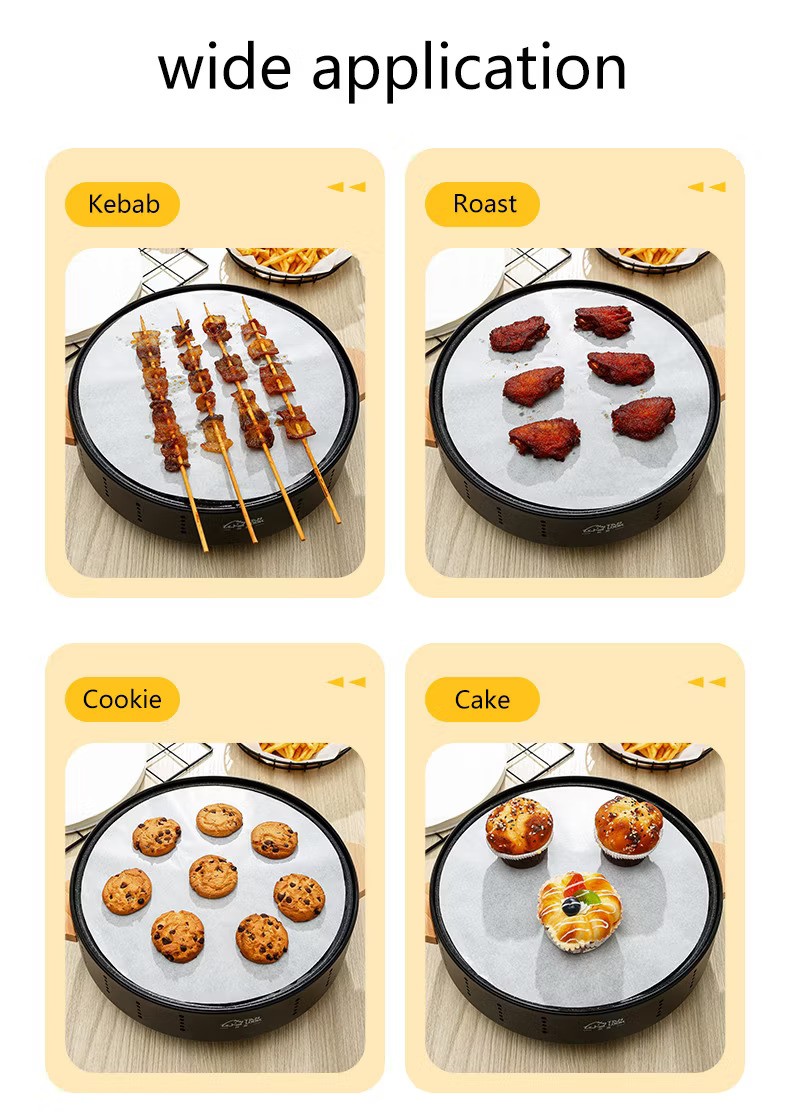

You can bake with greaseproof paper. It does not stick to food or trays. It handles heat well. Bakeries and kitchens use it a lot. It helps you bake safely and keeps things clean.

Why do food companies choose greaseproof paper?

Food companies want food to stay fresh and clean. Greaseproof paper helps with this. More people want good food packaging. Manufacturers make paper better for safety and the planet.

How do manufacturers test greaseproof paper for quality?

Manufacturers test for grease resistance and oil repellency. They also check contact angles. These tests make sure the paper is safe for food. The paper works well for packaging.