When you pick the right label release paper, your labels work well and last longer. The material you choose is important. Paper is cheaper but only good for short use. Polyester and vinyl are very strong. They can handle chemicals, sunlight, and water. Polypropylene is light and can be recycled. Look at the table below to compare:

| Label Material | Durability | Compliance Suitability | Key Features |

| Paper | Low | Short-term, low-risk | Cheap, easy to print, not good with water |

| Polyester | High | Good for hazardous | Handles chemicals, sunlight, and hot or cold places |

| Vinyl | High | Good for bumpy surfaces | Bends easily, strong, safe from water and chemicals |

| Polypropylene | Moderate | Light, eco-friendly | Handles chemicals, can be recycled, prints in many ways |

You also need to follow rules like UL, ANSI, and REACH. This keeps your labels safe and legal.

Key Takeaways

Pick the right label release paper for your needs. Think about how strong it is, where it will be used, and what you need it for. This helps your labels work well.

Follow rules like UL, ANSI, and REACH. These rules keep your labels safe and legal. They also protect your business and your customers.

Test your labels often to check quality. Look at how well they stick, how clear the print is, and how strong they are. This helps stop problems and keeps customers happy.

Keep label release paper in a cool, dry place. This stops damage and keeps your labels good. Good storage helps labels work better.

Use the right adhesive for your label material. Make sure the adhesive matches the surface and the place it will be used. This helps your labels last longer and work better.

Label Release Paper Overview

Definition and Function

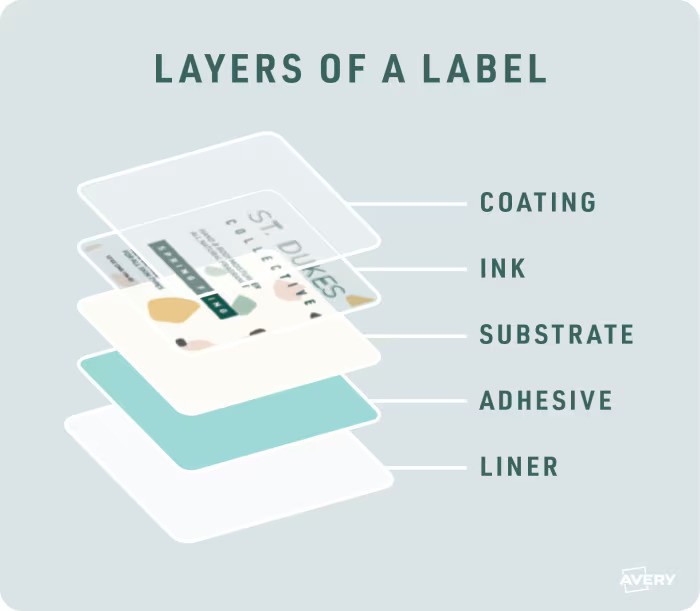

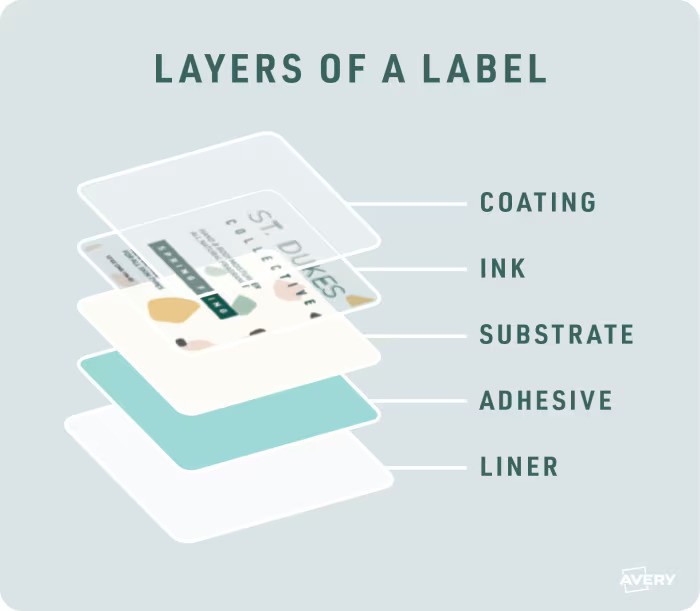

Label release paper is the backing for labels. It helps you peel labels off easily. Release liners like glassine and clay coated Kraft work well. They let you stick labels on surfaces without problems. You can also remove labels cleanly when needed. The liner should have the same thickness everywhere. This helps you cut labels right during printing. If the liner is not even, waste is hard to remove after cutting. The release level is important. If it is too tight, the label might tear when you pull it off. If it is too loose, the label could come off too soon.

When picking label release paper, think about how it works with adhesives. Some adhesives need a liner that lets go easily. Others need a liner that holds the label until you use it. You also need to think about the label material. Paper, polyester, vinyl, and polypropylene all work differently with adhesives and liners. Good results come from matching the liner, label, and adhesive.

Role in Labels Manufacturing

Label release paper is important for making pressure-sensitive labels. Many industries use it, like food packaging and electronics. It keeps labels safe and clean before you use them. Release liners protect the sticky part from dirt and water. This helps labels stick better when you use them.

Manufacturers care about cost when choosing label release paper. They look at how well it works, if it is good for the planet, and what the job needs. Most labels in North America use paper liners. These are cheap and work for many things. New trends are changing label release paper. Companies want liners that resist water and chemicals for medical labels. People also care more about the environment. So, there are more recycled and plant-based materials. Digital printing means you need special coatings for better prints.

Here is a table with some new trends in label release paper:

| Trend | Description |

| High-performance release liners | Better sticking, printing, and strength for medical labels. |

| Sustainability | More recycled and plant-based materials because of rules and what people want. |

| Technological advancements | Digital printing needs new liner features and coatings. |

| Customization | Online shopping and branding need special liners. |

| Specialized applications | Medical and electronics need liners with special features and rules. |

You need to pick the right label release paper for your labels, adhesives, and how you will use them. This gives you the best results.

Industry Standards for Label Release Paper

Image Source: unsplash

Material Specifications

It is important to pick the right materials for labels. The label release paper you choose changes how labels work in different places. Paper liners are good for short times. Polyester and vinyl liners last longer. They can handle water, chemicals, and sunlight. Polypropylene liners are lighter and can be recycled. You need to match label materials with the right adhesives. Some adhesives stick better to smooth liners. Others need liners with texture.

Pressure-sensitive labels show why the liner matters. The liner keeps the sticky part safe until you use it. The liner should be the same thickness everywhere. If the liner is uneven, printing labels can be hard. Labels might tear or not peel off well. You should check how easy it is to remove the liner. If it is too strong, the label can get damaged. If it is too weak, the label might fall off early.

Here is a table to compare common liner materials:

| Liner Material | Best Use Cases | Durability | Adhesive Compatibility |

| Paper | Food, retail, shipping | Low | Water-based, rubber |

| Polyester | Safety labels, chemicals | High | Solvent, acrylic |

| Vinyl | Outdoor, rough surfaces | High | Acrylic, hot melt |

| Polypropylene | Eco-friendly, light | Moderate | Acrylic, rubber |

Compliance Requirements

You need to follow rules when making labels. These rules keep people safe and help you follow the law. UL, ANSI, and REACH are three big safety standards. UL checks if labels can handle heat, chemicals, and wear. ANSI makes sure safety labels are easy to read. REACH looks at chemicals in label materials and adhesives. You must avoid using harmful chemicals.

Tip: Always look for the newest rules. Rules change often, so check them to keep your labels safe and legal.

You should keep notes about your label materials and adhesives. If you use recycled or plant-based liners, make sure they follow all safety rules. You need to test labels for strength and chemical resistance. If labels do not pass these tests, you cannot use them for safety or dangerous products.

Quality Benchmarks

You want labels to work well every time. Quality benchmarks help you check how labels perform. You should test how easy it is to peel labels off the liner. You need to see if labels stick to different surfaces. You must look for problems like curling, tearing, or bad printing. Good labels stay flat, peel off easily, and stick where you want.

Here are some steps to keep your labels high quality:

Test labels with different adhesives and surfaces.

Check liners for even thickness and smooth release.

Look at labels for clear print and color.

Store label release paper in a cool, dry place.

Teach workers to handle labels with care.

If you follow these steps, your labels work better and you waste less. You also meet rules and keep your customers happy.

Best Practices for Pressure-Sensitive Labels

Adhesive Compatibility

You need to use the right adhesive with the right label release paper. This helps labels stay strong and last longer. The adhesive you pick changes how well labels stick and how they look later. Think about where you will put the label. Also, think about the weather and how you will use the label. These things change how adhesives work.

Pick adhesives that match the surface. Smooth surfaces need one kind. Rough surfaces need another kind.

Think about the weather. Labels might get hot, cold, wet, or touch chemicals. Use adhesives that can handle these things.

Check how you will put on the label. Some adhesives are better for hand use. Others work better with machines.

Clean, dry, and smooth surfaces help adhesives stick better. Press down hard enough so the adhesive bonds well. Keep the temperature right when you put on the label. If you do these things, your labels work better and you have fewer problems.

Release Coatings

Release coatings help labels come off the liner easily. They also help labels stick to surfaces without trouble. Silicone coatings work best for machines in big label printing jobs. These coatings control how easy it is to peel labels off. You can change the release level for different peel speeds and label types.

SILCOLEASE™ release coatings let you change how labels peel for many needs. You can pick different kinds of release coatings for your job. Here is a table that shows common types:

| Form | Cure rate | Release | Comments |

| Solvent borne | Fast to slow | Easy to tight | Dull to glossy, sticks well |

| Waterborne | Medium to slow | Easy to medium | Some need extra curing |

| Solventless (100% solids) | Fast to medium | Easy to tight | Glossy, gives premium release |

You can also use special polymers for release coatings. These include long-chain alkyl carboxylic acids, esters, (meth)acrylates, polyurethanes, silicone polymers, and fluorinated polymers. Each type gives different release features. Pick the coating that matches your label materials and adhesives.

Application Tips

The release liner helps the label peel off easily when you use it. Good liners let you put on labels fast and without damage.

You want labels to last and look nice. Follow these tips for the best results:

Surface Compatibility: Check the surface for texture, shape, and material. This helps you pick the right adhesives and label materials.

Environmental Conditions: Use labels that can handle heat, cold, wet, and chemicals. This keeps labels strong and clear.

Label Longevity: Decide if you need labels for a short time or a long time. Use adhesives and materials that fit your needs.

Clean and dry surfaces help adhesives stick better. Press down when you put on the label. Keep the temperature steady when you apply labels. These steps help labels stay in place and look good.

Test labels before using lots of them. Try different adhesives and release coatings to see what works best. Store label release paper in a cool, dry place to keep it nice. Teach workers how to handle labels and liners so they do not get damaged.

If you follow these best practices, your labels stick better and you waste less. Your labels will look good, stay on, and last longer in many places.

Storage and Handling of Label Release Paper

Storage Guidelines

You must keep label release paper in good conditions. Store it in a cool, dry place. The temperature should be between 68°F and 75°F. Humidity should stay between 40% and 50%. This helps labels keep their shape and stick well. If labels are near heat, adhesives can get hard. Labels might fall off too soon. Too much humidity makes labels swell or curl. Not enough humidity can dry out labels and make them crack.

Keep paper labels away from water so they do not fade.

Do not put vinyl and polyester labels near heat. This stops them from bending.

Polypropylene labels last longer below 75°F in dry places.

Dissolvable materials need plastic wrap and quick use within six months.

Repositionable and acrylic adhesives work best in cool, dry spots. Keep acrylic adhesives wrapped until you use them.

Rubber-based adhesives need air and dryness.

High-temperature adhesives should be kept in dark, dry places.

Labels for food or medicine may need special storage rules.

Put unused labels back in their original package. Seal the package after each use. Keep labels away from sunlight, heat, and water. This helps labels last longer and stay safe for the environment.

Tip: Storing label release paper the right way keeps it ready to use and helps labels stay strong.

Handling Techniques

Handle label release paper gently so it does not get damaged. Always work in a clean area. Use clean tools when you cut or use labels. Follow careful handling steps. Check labels often to find problems early.

Only open outer bags in special clean areas.

Wear gloves and use clean wipes when moving labels.

Store tapes and labels in sealed boxes or dispensers made for clean rooms.

Good handling keeps labels free from dust and dirt. This helps labels stick better and last longer. Strong adhesives work best when labels are clean and safe. You help labels work well and last longer by following these steps.

Note: Careful handling helps the environment and keeps labels ready for any job.

Common Challenges with Labels

Adhesion Issues

Sometimes, labels do not stick well or fall off early. This usually happens because the label release paper and adhesive do not work together right. Here are some problems you might see:

Tunneling: This happens when the vinyl face stock gets smaller or the liner gets bigger from water. You will notice bubbles or tunnels under the label.

Tight Release: If the adhesive is too strong for the liner, peeling the label off is hard. This can break the label or slow you down.

Adhesive Lock-Up: If the adhesive and liner do not match, the label might not come off at all. This wastes labels and takes more time.

You can stop these problems by trying different adhesives and liners before you start a big job.

Environmental Factors

Labels can have problems because of the environment. Temperature and humidity change how labels work. The table below shows what happens in different conditions:

| Environmental Factor | Effect on Label Performance |

| High Temperature | Adhesives get soft, labels fall off, ink can fade or smear |

| Low Temperature | Adhesives lose stick, labels might crack or drop off |

| High Humidity | Paper labels soak up water, bend, and do not stick |

| Synthetic Labels | Do not soak up water, keep shape and stickiness in wet places |

Pick the right label material for your weather. Synthetic labels are better for wet or humid places. Paper labels last longer if you keep them dry and cool.

Waste Management

You should manage waste from label release paper to help the planet and save money. Many companies use these ideas:

Make print layouts that use less material and leave fewer extra labels.

Use digital printing for small jobs to waste less.

Check for mistakes early so you do not waste labels.

Pick eco-friendly materials like recyclable or biodegradable labels and liners.

Use lean manufacturing to remove steps that do not help.

Making label release paper uses lots of water and energy. It also makes waste and pollution. Recycling helps lower pollution, but some chemicals can stay. You can help by choosing better materials and making your process better.

Ensuring Compliance and Performance

Testing and Quality Assurance

You have to test your labels to make sure they work. Testing helps you find problems before customers get the labels. One big test is the label adhesion test. This test checks if the adhesive is strong enough. You cut a piece of label and stick it on a steel plate. Then, a machine pulls the label off the plate. This test uses the ASTM D3330 standard for peel adhesion. Here is a table that explains the test:

| Testing Method | Description |

| Label Adhesion Test | Checks how strong the adhesive is on labels. |

| Procedure | Cut a sample, stick it to a steel plate, and use a tester to pull it off. |

| Standards | Uses ASTM D3330 for peel adhesion testing. |

You should also look at print quality and see if labels curl. Check if labels stick to different surfaces too. Testing keeps your labels safe and strong, especially for safety labels.

Documentation

Good documentation shows your labels follow all the rules. You need to keep records for every step you take. This helps you prove you follow the rules during audits. Here are some ways to keep your documents organized:

Groups like the FDA and EMA want labels to have the right product details. You must use an approved system to control versions and track changes. This keeps your label process safe and easy to follow.

Continuous Improvement

You can make your labels better by always looking for new ideas. Ask your team for ways to improve and try new methods. Try using rolls to remove labels faster or print-on-demand to save money and waste less. Here is a table with ways to make your label process better:

| Continuous Improvement Practice | Description |

| Check your labeling steps often | Get ideas from workers and test new ways to work faster. Try automation for better results. |

| Find ways to make label design better | Change label design to make removal quicker, like using rolls. |

| Switch to print-on-demand labels | This lowers inventory costs and lets you use more data. |

| Use label kits | Put many labels on one sheet to save time and keep things the same. |

| Know why you use each label | Understand the reason for each label to help you improve. |

Tip: When you know why you use a label, you can make it work better.

You can ensure your label release paper meets industry standards by following clear steps:

Choose materials that fit your needs.

Print and finish labels with care.

Die-cut and rewind for custom shapes.

Inspect labels for quality before shipping.

| Step | Description |

| 1 | Know your manufacturing abilities. |

| 2 | Plan each step in your workflow. |

| 3 | Link every process to the final product. |

Stay alert to changing rules. Test labels often and use caution labels to prevent mistakes. When you follow best practices, your labels stay strong and compliant.

FAQ

What is the main purpose of label release paper?

Label release paper helps you take labels off easily. It keeps the sticky part safe until you use it. This makes sure you can put labels on smoothly every time.

How do you choose the right release liner for your label?

Pick a liner that matches your label material and adhesive. Think about where you will use the label. Try out different liners to find the one that works best for you.

Can you recycle label release paper?

Some release papers can be recycled, like ones made from paper or polypropylene. Ask your local recycling center if they accept them. Always take off any leftover adhesive before you recycle.

What problems can happen if you store label release paper wrong?

If you keep release paper in a hot or wet place, it might curl, crack, or not stick well. Always store it in a cool, dry spot to keep it working right.