You might not know that receipt paper is not just plain paper. Companies mix natural fibers with chemicals, which are key ingredients of paper, to make it print fast. The things in receipt paper can impact your health and nature. When you learn what is in these slips, you can choose better for yourself and the Earth.

Key Takeaways

Receipt paper has chemicals like BPA and BPS. These can hurt your health. Touching receipts a lot can raise these chemicals in your body.

Picking phenol-free thermal paper lowers your risk. Try to find receipts marked 'BPA-free' or 'BPS-free.' These are safer choices.

Not using printed receipts helps cut waste and pollution. Choosing digital receipts is better for your health and the planet.

Knowing what is in receipt paper helps you choose wisely. Ask stores about their paper and look for safer kinds.

Many companies now use safer receipt paper. When you ask for these, you help make safer products more popular.

Ingredients of Paper

When you look at paper, you see more than wood fibers. Paper is made from natural things and chemicals. These work together to give paper its special features. You might ask why paper is strong, smooth, or bright. Let’s look at the main parts of paper. This will help you see how each part matters.

Cellulose and Hemicellulose

Cellulose and hemicellulose are the main fibers in paper. They come from wood pulp, which starts the paper-making process. Cellulose makes paper strong and gives it shape. Hemicellulose makes paper bend without breaking. These two fibers work together. They help make paper tough but easy to use.

| Component | Role in Paper Structure and Properties |

| Cellulose | Gives paper strength and helps it keep its shape. |

| Hemicellulose | Makes paper flexible and adds to its strength. |

| Interaction | Helps paper last longer and feel better to use. |

Lignin and Fillers

Lignin is another part found in wood pulp. It holds fibers together but can turn paper yellow. To make paper better, companies add fillers like calcium carbonate and clay. These make paper brighter, thicker, and easier to print on. Calcium carbonate makes paper whiter and stronger. Fillers also change how smooth the paper feels.

Tip: Fillers like calcium carbonate make paper brighter and help you get clearer prints.

Small filler pieces let companies change how paper acts.

Fillers help block light, which is good for printing.

White fillers make paper look brighter and words easier to read.

Fillers make paper smoother, so prints look and feel better.

Additives and Coatings

Additives and coatings are also used in paper. These include wax, dyes, and sizing agents. They help ink stay on the paper and stop smudges. Coatings make the paper surface even and smooth. This is very important for receipt paper. Other additives, like defoamers and biocides, stop bubbles and germs from ruining the paper.

Sizing agents stop ink from spreading.

Dyes and pigments change the color of the paper.

Fillers make paper thicker and block more light.

Whiteners make paper look brighter.

Dispersants and defoamers keep the coating smooth.

Knowing what is in paper helps you see why some paper feels different or lasts longer. Every part has a job. Together, they make the paper you use every day.

Chemical Composition of Paper Receipts

When you look at a thermal receipt, you see more than just paper. The chemical composition of paper receipts includes special chemicals that help create the printed image. These chemicals work together to make receipts fast and easy to print. You will find that the chemical composition of these receipts is different from regular paper because of the unique chemical ingredients of paper used in thermal printing.

BPA (Bisphenol A)

BPA stands for Bisphenol A. You find this chemical in many thermal receipts. Companies use BPA because it is stable and can handle heat well. When you touch a receipt, you might not realize that BPA sits in the coating on the paper. This chemical acts as a color developer. When the printer heats the paper, BPA reacts with other chemicals to create the dark letters and numbers you see.

Many stores still use BPA in their receipts. In a study of receipts from 39 countries, 69% of samples contained BPA as a color developer. Some places even found BPA levels above safe limits. For example, in Sharjah, UAE, 60% of samples had BPA levels higher than what the European Union allows.

You can see how much BPA shows up in receipts by looking at this table:

| Study | Concentration Range (mg/g) |

| Frankowski et al. | Exceeded EU limit (0.2 mg/g) in 22% of samples |

| Molina-Molina et al. | Up to 20.3 mg/g in Spain, 90.9% in Brazil, 51.1% in France |

| Wong et al. | 0.124–871.17 mg/kg |

| Zhang et al. | 0.696 mg/g (supermarket), 0.937 mg/g (laundry), 0.306–3.780 mg/g (taxi tickets) |

| Castro et al. | 0.005 to 6.30% |

| Yalcin et al. | 0.40±0.11 mg/g to 21.65 ± 0.83 mg/g |

| Geens et al. | Above 0.9% in 73% of samples |

| Lu et al. | 2.58 to 14.7 mg/g |

| Russo et al. | 107.47 μg/100 mg of paper |

Note: BPA helps make receipts clear and easy to read, but it can also pose health risks if you touch it often.

BPS (Bisphenol S)

BPS stands for Bisphenol S. Some companies use BPS instead of BPA in thermal receipts. BPS works in a similar way to BPA. It helps develop color when the printer heats the paper. You might think BPS is safer, but it still raises concerns.

BPS does not show up as often as BPA. In one study, BPA appeared in 67.5% of thermal receipt samples, while BPS was found in only 25%. The amount of BPS in receipts is usually lower than BPA. For example, BPA concentrations ranged from 0.83% to 1.71%, while BPS ranged from 0.61% to 0.96%. Both chemicals can go above the EU safety limit of 0.02% by weight in thermal paper.

Tip: Even if a receipt says "BPA-free," it might still contain BPS or other chemicals with similar effects.

How They Work

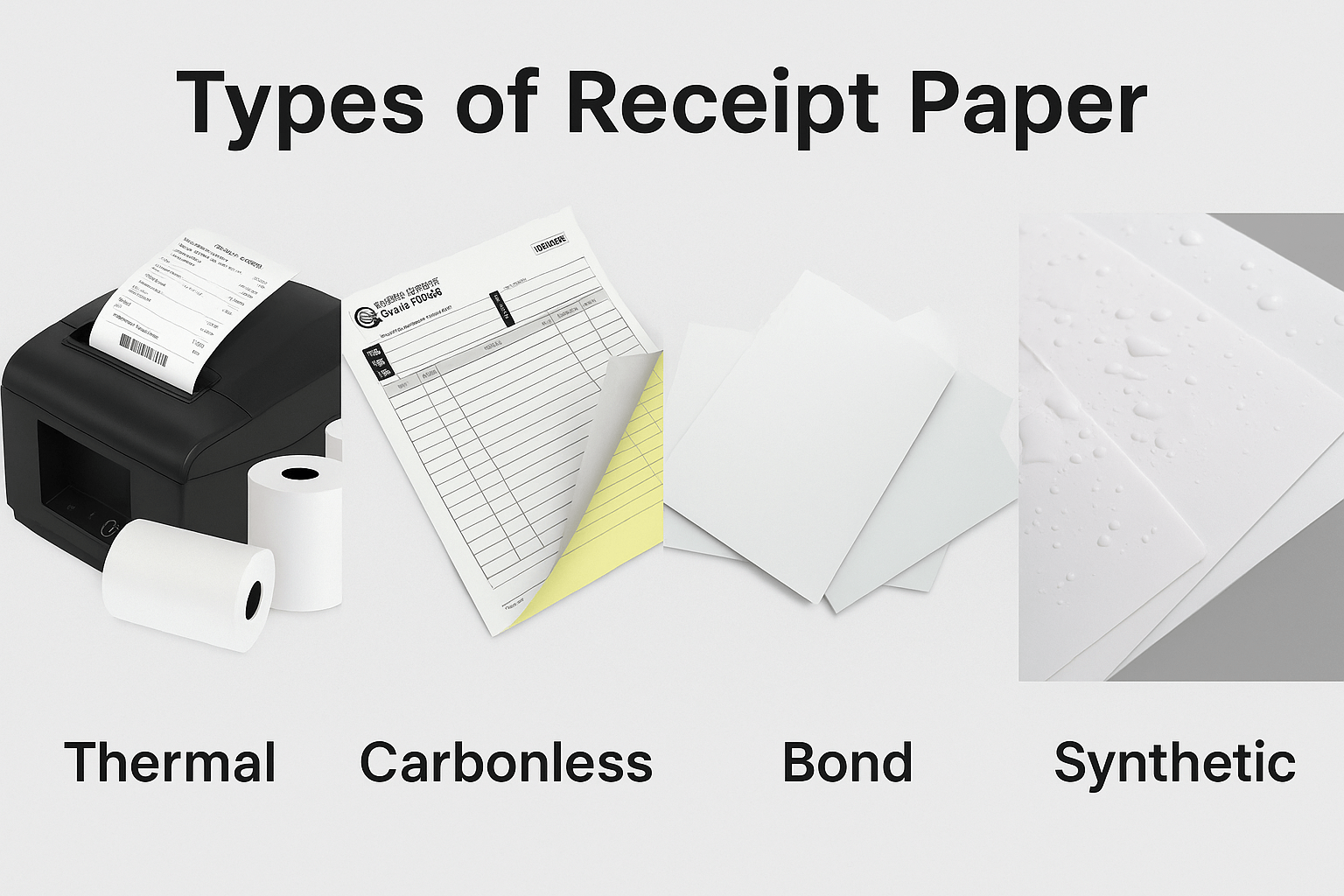

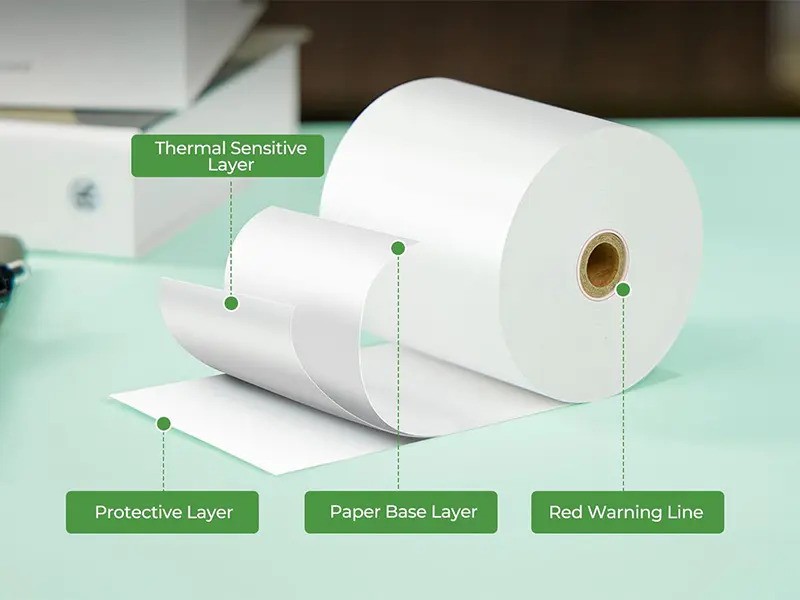

You might wonder how these chemicals make words appear on receipts. The chemical composition of thermal paper includes several layers. The base paper comes from wood pulp and is made smooth and heat-resistant. On top of this, companies add a coating with special chemical ingredients of paper.

Here is what you find in the coating:

Leuco dyes: These dyes start out colorless. When heated, they react and turn dark.

Developers: BPA or BPS act as developers. They react with the leuco dye when the printer heats the paper.

Sensitisers: These help the dye react at the right temperature.

Stabilisers: These keep the print from fading in heat or humidity.

Protective coating: This layer keeps the print clear and protects the chemicals.

When you use a thermal printer, it heats tiny spots on the paper. The heat causes the developer (BPA or BPS) to react with the leuco dye. This reaction creates the black or blue marks you see as text or images. The chemical composition of the coating makes this process fast and reliable.

You can see the main chemical ingredients of paper receipts in this list:

BPA or BPS (color developer)

Leuco dye (colorless dye that reacts to heat)

Sensitiser (helps the reaction happen at the right temperature)

Stabiliser (keeps the print from fading)

Protective coating (adds durability)

Callout: The chemical composition of paper receipts has changed over time. In 2013/14, 82.2% of receipts used BPA, while only 3.1% used BPS. By 2021, new developers like Pergafast® 201 started to appear, showing a shift toward safer options.

Understanding the chemical composition in your receipts helps you make better choices. You can look for receipts labeled "phenol-free" or ask stores about their paper. This knowledge lets you protect your health and the environment.

Health and Environmental Impact

Health Risks

When you touch thermal receipts, you touch chemicals like BPA and BPS. Your skin can take in these chemicals, especially BPA. Studies show BPA goes through skin easier than BPS. After one work shift without gloves, workers had twice as much BPA in their urine. Wearing gloves stopped this from happening.

| Chemical | Absorption Rate (%) after 24h |

| BPA | 25% |

| D-8 | 17% |

| BPS | 0.4% |

| PF201 | <LLOQ |

More BPA in your body can cause health problems. Scientists found people with more BPA in their urine had higher insulin levels. They also had more insulin resistance. This can raise your chance of getting diabetes. BPS is absorbed less but still worries experts. You may have trouble with fertility, a bigger chance of some cancers, learning and behavior problems, and issues with your thyroid or metabolism.

Fertility problems

Higher risk of some cancers

Learning and behavior issues

Thyroid or metabolism problems

Note: Lab studies show BPA moves through skin faster than BPS. Try to avoid touching receipts to lower your risk.

Environmental Concerns

Receipt paper hurts the environment in many ways. Every year, companies make over 300 billion paper receipts worldwide. In the United States, about 9.6 million trees are cut down just for receipts. Most thermal receipts have BPA or BPS, which makes recycling hard. These chemicals can get into recycled products and stay in nature for a long time.

BPA and BPS from receipts pollute air, water, and soil. You can find these chemicals on almost every receipt. They harm tiny living things in soil and can affect your hormones. The Minnesota Pollution Control Agency says not to recycle receipts because BPA and BPS can leak into water. Bisphenol A is now a common pollutant in nature, mostly because of thermal paper recycling and related industries.

Tip: You can help the environment by saying no to receipts when you can and picking digital options. This cuts down on waste and chemical pollution.

Safer Alternatives

Phenol-Free Options

You can pick phenol-free thermal paper to avoid harmful chemicals. This kind of paper does not use BPA or BPS. Makers use other image developers that do not have phenol compounds. Choosing phenol-free receipts helps lower health risks and protects nature. These papers start with clean pulp and skip strong chemicals. You get a safer product that is better for recycling.

Phenol-free thermal paper uses different color developers.

The paper does not have BPA or BPS, so you avoid those risks.

Companies use pulp that does not need phenol-based chemistry.

Some phenol-free choices still need more study to show they are much safer than BPA or BPS. You should know that skin absorption rates for some new options may not be much lower than for BPA. Even so, phenol-free paper helps you stay away from the most common harmful chemicals.

Tip: Look for receipts that say "phenol-free" or "BPA and BPS free" to make safer choices.

Other Chemical Alternatives

There are new chemical choices for thermal receipt paper. These use different coatings and developers instead of BPA and BPS. Many start with paper pulp and add safer materials.

| Alternative | Description | Source |

| PHBH Coating | Biodegradable polymer coating that resists heat and water, improving print quality. | Nippon Paper Industries, Kaneka Corp. |

| Lignin-based Polymers | Biodegradable, CO2-neutral polymers from lignin, offering thermal stability. | Florida State University |

| Phenol-free Color Developer | Stable developer that improves performance and storage. | Koehler |

| Bio-based PAES Copolymer | Copolymer from renewable sources, free of BPA and BPS, with strong resistance. | Solvay Specialty Polymers |

| Improved Thermosensitive Material | Better color development and lower cytotoxicity than BPA and BPS. | Sanko |

| Water-dispersible Thermal Material | Dissolves in water, suitable for sustainable uses. | Appvion Operations |

Some choices, like Pergafast 201 and D-8, are still part of the phenol family. You should know these may cause cytotoxicity. Always check safety data before trusting a new chemical. The best choices use pulp with coatings that do not add health risks.

Identifying Safer Receipts

You can find safer receipt paper by checking labels and certifications. Many products now say "BPA and BPS free." This means the paper uses other developers and follows safety rules. Look for these labels when you shop.

Receipts marked "BPA and BPS free" use safer chemicals.

Some rolls, like Blue4est, are chemical-free and can be recycled.

About 20% of stores now use safer receipt paper.

You can also look for certifications. These show the paper meets high safety and environmental standards.

| Certification | Description |

| Ineris Certification | Confirms no phenolic compounds and BPA-free status. |

| ISO 14001 | Ensures good environmental management. |

| EMAS | Tracks and improves environmental performance. |

| PEFC/FSC | Proves sustainable sourcing of paper pulp. |

Note: More people now know about safer receipts. The use of non-bisphenol alternatives in receipts grew from 2% to 20% in recent years. You help make change happen when you ask for safer receipts.

You have learned that most receipt paper has BPA or BPS. These chemicals can mess with hormones and may cause cancer. People who work in fast food and shoppers touch receipts a lot. You can keep yourself safe by doing these things:

Say no to printed receipts or pick digital ones.

Wash your hands after you touch receipts.

Do not let kids play with receipts.

| Organization | What They Do for Safer Receipts |

| Ecology Center | Wants stores to stop using toxic bisphenols and give digital receipts. |

| Toxic-Free Future | Pushes stores to stop using harmful chemicals. |

| Green America | Asks for safer, paperless choices to help people. |

You help yourself and nature when you ask for safer receipts and make smart choices.

FAQ

What makes receipt paper different from regular paper?

You see receipt paper made with special coatings. Companies use wood pulp for both types, but thermal receipts need extra chemicals. The coating reacts to heat, so you get printed words without ink.

Can you recycle receipt paper made from wood pulp?

Most recycling centers do not accept thermal receipts. The chemicals in the coating mix with recycled pulp and can cause pollution. You help the environment by choosing digital receipts or asking for phenol-free options.

Why do companies use wood pulp in receipt paper?

Wood pulp gives paper its strength and flexibility. You find wood pulp in almost every kind of paper. Companies use it because it is cheap, easy to process, and works well with additives.

Does pulp from different trees change the quality of receipt paper?

Yes, the type of pulp matters. Softwood pulp makes paper strong. Hardwood pulp gives a smoother surface. Companies mix different pulps to get the right balance for printing and durability.

How can you tell if a receipt uses safer pulp and chemicals?

Look for labels that say "BPA-free," "BPS-free," or "phenol-free." Some receipts use pulp from certified sources. You can ask stores about their paper or check for eco-friendly certifications.