Metallized paper feels like regular paper but looks shiny. You often see it in fancy packaging and bright labels. Its shiny surface helps products stand out on shelves. The aluminum coating makes it look nice and protects it. This coating gives the paper a shiny look. It also makes the paper strong against tearing, water, and light.

| Feature | Metallized Paper | Standard Paper |

| Reflective Surface | Shiny and looks very nice | Not shiny and less nice |

| Barrier Properties | Great at stopping water, air, and light | Not much protection |

| Strength and Durability | Hard to tear or scratch | Easier to damage |

Experts think the metallized paper market will grow 4-5% each year for five years.

The market could be worth USD 6.14 billion in 2032, up from USD 4.47 billion in 2024.

Key Takeaways

Metallized paper has a shiny look. This makes products easy to see on shelves. The aluminum coating keeps prints safe from rips, water, and light. This helps them last longer. Metallized finishes can help brands look better. They also make products seem high quality. People use metallized paper for packaging, labels, and ads. These all look special because of the shiny effect. You can recycle metallized paper easily. It goes with regular paper, so it is good for the environment.

Metallized Paper Overview

Features of Metallized Paper

Metallic paper is easy to spot because it shines. The shiny look comes from a thin aluminum layer. This layer is added during metallization. The paper feels normal but looks metallic. You can see how metallized paper is different from other specialty papers in the table below:

| Property | Metallized Paper | Other Specialty Papers |

| Manufacturing Process | Uses vaporized aluminum on paper | Many ways, often no metal layers |

| Barrier Properties | Blocks light, moisture, and odor | Not as good against moisture and grease |

| Visual Appearance | Shiny metallic look with paper feel | Looks different, usually not shiny |

Most metallic paper is very glossy and smooth. You can print on it with many types of printers. It is safe for packaging. It comes in different sizes for many uses. The metallic surface keeps water and scratches away. Your designs stay bright and clean.

Tip: You can recycle metallic paper with regular paper. It breaks down faster than plastic films.

Benefits for Print Projects

Metallic paper gives you many benefits for printing:

It looks shiny and grabs attention.

It helps your brand look high quality.

The metallized layer keeps prints safe from tearing and water.

You can make special designs with different printing methods.

Metallic paper is great for packaging food and drinks. It keeps products safe from moisture. The shiny surface lets you print nice graphics. This makes your packaging look good and stay strong.

| Benefit | Impact on Shelf Impact and Consumer Perception |

| Enhanced Visual Appeal | Makes people notice your product |

| Improved Shelf Presence | Helps people pick your product |

| Elevated Perception | Makes your brand look better and more valuable |

Metallic paper looks nice and protects your prints. It does not get damaged by water or scratches. The shiny surface makes your products look fancy and helps them stand out.

Production Methods

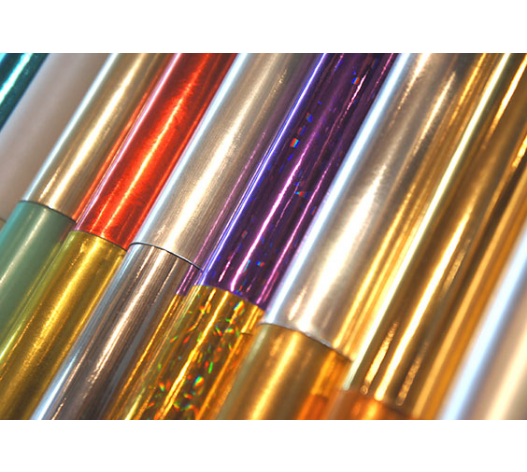

Image Source: pexels

Metallized paper gets its special look and strength from how it is made. There are a few ways to make the shiny finish and strong surface. These ways help your prints stand out. The main ways are lamination, vacuum metallization, and surface treatments like varnishing and lacquering.

Lamination Process

Lamination makes metallic paper shiny and tough. Here are the main steps for making metallized paper with lamination:

Varnishing: First, a thin layer of varnish goes on the paper. This step gets the paper ready for the next part. The paper dries until it has just a little moisture left.

Metallization: Next, the paper goes into a chamber. Aluminum is added as a vapor. This step gives the paper its metallic look.

Lacquering: Last, a layer of lacquer covers the paper. A corona treatment helps the lacquer stick and keeps the surface safe.

Tip: Every step in lamination makes the paper look and work better.

The type of lamination material changes how the paper looks and works. Here is a table to compare different materials:

| Lamination Material | Appearance Impact | Performance Impact |

| Foils | Best shiny look | Great at blocking water and air |

| Laminates | Looks can be changed | How it works depends on the layers |

| Metalized Films | Blocks water and air well | Harder to recycle |

| Coated Papers | Shiny but not very reflective | Not as good at blocking water and air |

| Metallized Paper | Real metallic look, good at blocking | Light and saves money for packaging |

Lamination films change how light bounces off the paper. Matte films spread out the light and make colors soft. Gloss films bounce more light and make colors bright. Metalized film lamination also keeps out water and air, blocks light, and makes packaging stronger.

Vacuum Metallization

Vacuum metallization is a popular way to make a metallic finish. This method uses less stuff and less energy than other ways. It is better for the environment. Here are the steps for vacuum metallization:

Put the paper in a vacuum chamber.

Take out the air to make a vacuum.

Heat up aluminum until it turns to vapor.

The metal vapor lands on the paper.

Let the coating cool and get hard.

Take out the finished metallic paper.

Vacuum metallization uses about 0.5 grams of aluminum for each square meter. This makes a thin, even metallic layer. You use much less aluminum than with foil lamination. Foil lamination can use 50 to 100 times more. This way saves materials and energy. The result is a shiny, smooth metallic layer that makes prints look great.

Varnishing and Lacquering

Varnishing and lacquering are important last steps for metallized paper. These coatings give extra protection and make the paper look better.

Clear coatings keep away scratches, rust, and water.

They help the metallic shine stay bright and stop the surface from getting dull.

These treatments also make the paper feel smooth and look nice for packaging and labels.

You can pick matte or gloss finishes. Matte coatings spread out light and look soft. Gloss coatings bounce more light and make the metallic surface stand out. Both choices help your metallic paper stay strong and look good for any print job.

Visual Effects of Metallic Paper

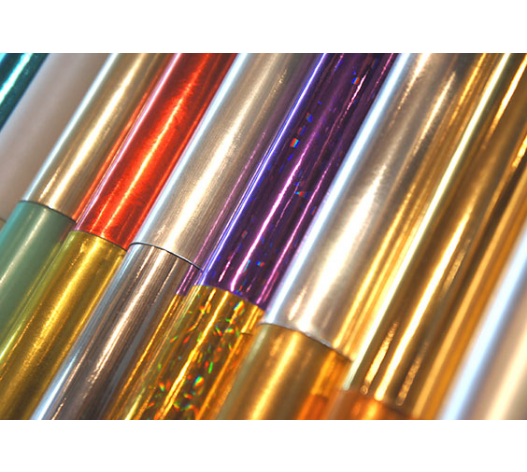

Image Source: unsplash

Metallized paper lets you be creative in many ways. You can use it for packaging, labels, and fancy prints. The shiny effects help your products get noticed and remembered. There are three main visual effects you can make with metallized paper: holographic effects, embossing, and reflective finishes.

Holographic Effects

Holographic effects make packaging look special and cool. When you use holographic metallized paper, the colors and patterns change as you move it. This happens because of a special process. First, a thin shiny aluminum layer is put on the paper. Next, tiny patterns are pressed into the surface. These small lines and shapes break up light into many colors. This makes the paper look like it has many layers and moves.

You see holographic effects a lot in makeup, clothes, and shopping bags. They help products stand out and get attention in stores.

"Fun holographic labels really stand out and make people look at your product."

Here are some popular holographic effects used in packaging and ads:

| Holographic Effect Type | Description |

| Reflective Accents | Makes flat surfaces look 3D and more interesting. |

| Design Elements | Uses dots, lines, waves, and other shapes for cool looks. |

Holographic finishes make products pop on store shelves.

You see them a lot in makeup and fashion.

Brands use them for logos and pictures on bags and pouches.

Holographic and metallic finishes play with light in a special way. This grabs people’s attention. These effects also help tell your brand’s story and make your packaging hard to copy. This makes your brand stand out and helps customers trust you.

Embossing

Embossing gives metallic paper a raised feel and look. When you emboss, you press a pattern into the paper. This makes some parts stick up so you can see and touch them. Embossing works well with metallic paper because the raised parts shine and make shadows. This makes your design stand out.

Embossing makes packaging feel nice and can help sell more.

Embossed metallic prints feel fancy and make your brand look special.

Raised designs make your product easier to remember.

Embossing is not just for looks. It makes your packaging feel high quality. When people pick up your product, they notice the difference right away. This effect helps your brand stand out and makes your prints look classy.

Reflective Finishes

Reflective finishes are a classic choice for metallized paper. You can pick glossy, matte, holographic, or textured finishes. Each one gives your packaging a different look and feel. Glossy finishes make colors bright and bold. Matte finishes give a soft shine. Holographic and textured finishes add extra layers.

| Requirement | Description |

| Type of Finish | Choices include glossy, matte, holographic, and textured, each with its own look. |

| Paper Weight | Can be light or heavy, which changes how strong and fancy it feels. |

| Printability and Ink Compatibility | The paper should work well with your printer and inks. |

| Durability and Resistance | It should not get ruined by water, scratches, or sunlight. |

| Sustainability Considerations | Pick options that can be recycled or break down easily, and are made responsibly. |

When you compare reflective finishes to foil stamping, you see some big differences:

| Method | Visual Impact | Cost Comparison |

| Foil Stamping | Very bold and eye-catching | Costs more because it is harder to do |

| Metallic Ink | Looks nice but not as bright | Cheaper, especially for lots of prints |

Foil stamping costs more because it needs special tools and machines.

Metallic ink is cheaper, especially if you print a lot.

Foil stamping gives a strong, lasting finish. It is good for things that get used a lot, like fancy prints and packaging. Metallic ink looks nice but can wear off over time. If you want your prints to last, foil stamping is better.

Metallized paper does more than just look shiny. It helps you get noticed, share your brand’s story, and make your product special for customers. Using metallized finishes makes your products different and helps build a strong brand.

Creative Applications

Packaging and Labels

Metallized paper is used in lots of packaging and labels. It makes products look shiny and grabs your attention. This paper keeps things safe from water and light. Food, makeup, and fancy items stay fresh and protected. Wine and beer labels use metallic paper to stand out on shelves. Many brands pick metallized finishes for special projects to impress people.

| Application Type | Description |

| Packaging | Used for strong branding and keeps out light and water. It is common in food, makeup, and fancy packaging. |

| Labels | Makes personal care and drink labels look better. Wine and beer bottles stand out more. |

| Publishing | Used for magazine covers, brochures, and reports to look more interesting. |

| Decorative | Used in greeting cards and fancy boxes. It can be embossed and show cool holographic effects. |

You can print on metallized paper in many ways. Offset, flexography, digital, cold foil, and foil stamping all work. These ways help make labels that do not tear or get wet. The metallic layer makes packaging stronger and last longer.

Marketing Materials

Metallized paper is good for marketing things like brochures and business cards. Metallic business cards make a strong first impression. Shiny foil cards help people remember your brand. Brochures with metallic looks get noticed at events and shows. You can use metallic inks, foil stamping, or digital printing to add shine and texture.

Tip: Metallic finishes make your marketing stand out and show your brand is high quality.

Specialty Uses

Metallized paper is great for special uses. Event tickets, security cards, and certificates use it for extra safety. Holograms, watermarks, and serial numbers stop fakes. You can add UV coating or thermal printing for more protection. These features help control who gets in and keep events safe.

Metallized paper gives you lots of choices for creative and fancy projects. You can use it for packaging, labels, marketing, and security printing. The right printing and finish make your projects shine.

You can use metallized paper to make your prints pop. The way it is made and its shiny look make it different from normal paper.

Metallized films make packaging look cooler and help products stand out.

The metal layer gives special effects you cannot get with regular printing.

Research shows packaging with metallized finishes gets noticed 37% more in stores.

Try metallic finishes for your next project and see how it changes things.

FAQ

What printers work best with metallized paper?

You can use offset, flexography, digital, and screen printers. Check your printer’s settings before you start. Some inks might need changes for the shiny surface.

Is metallized paper safe for food packaging?

Yes, metallized paper is safe for food packaging. The aluminum layer keeps food safe from water and light. Always check for food-safe labels on the product.

Can you recycle metallized paper?

Most metallized paper can be recycled. You can put it with regular paper recycling. The thin metal layer breaks down when recycled.

How do you choose between matte and glossy finishes?

Matte gives a soft and gentle look.

Glossy makes colors bright and bold.

Think about your brand style and how you want your product to look.