You see kraft packaging almost every day. Kraft paper is made from wood pulp. The kraft process gives it a brown color and strong fibers. Kraftliner is a kind of kraft paper. People use it for the outside layers of corrugated boxes. Kraft paper and kraftliner are strong and last a long time. They are also a good choice for the environment. Many industries pick kraft because it is tough and eco-friendly.

Key Takeaways

Kraftliner is a tough and green packaging material. It is made from wood fibers. It works well for corrugated boxes.

Picking kraftliner helps the planet. It uses recycled stuff and cuts down on trash.

Kraftliner is great for printing. It is good for packaging with logos that get noticed.

Kraftliner can be used in many ways. You can use it for shipping, stores, and special uses.

Check for eco-certifications like FSC and PEFC. These show your kraftliner comes from good sources.

Kraftliner Overview

What is Kraftliner?

Kraftliner is used in lots of packaging. It is a strong paperboard made mostly from wood fibers. You see it on the outside of corrugated boxes. Manufacturers use fibers from trees or old boxes to make kraftliner.

To make kraftliner, workers start with wood or used boxes. If they use virgin fibers, here are the steps:

Workers take off bark and cut logs into chips.

The chips go through the kraft pulping process with chemicals.

The pulp has mostly water and a little fiber.

Machines take out water until there is more fiber.

Presses squeeze out even more water.

The pulp dries until it is almost all fiber.

Workers add starch to make the paper stronger.

The kraftliner is rolled up and sent to box plants.

If recycled fibers are used, the steps change a bit:

Old boxes are mixed with water to make a slurry.

The slurry is cleaned to get rid of dirt and glue.

The cleaned pulp is dried and pressed like virgin fiber.

Kraftliner has several important parts. Here is a table that shows what is inside:

| Component Type | Description |

| Fibers | Made of short chemical eucalyptus fiber in layers. |

| Additives | Includes things like starch, polymers, and nanocelluloses. |

| Mass Additives | Starch is put on the surface to make it stronger. |

| Properties | It resists bursting, is stiff, tears less, and has Gurley porosity. |

| Optical Properties | The top layer uses bleached kraft pulp for whiteness and better printing. |

Kraftliner is tough and stiff. It works well for heavy-duty jobs. It can handle moisture and rough treatment. You can print on it, so it is good for branded packaging.

Tip: Choosing kraftliner helps forests and recycling.

Kraft Paper vs. Kraftliner

You might wonder how kraft paper and kraftliner are different. Both are made using the kraft process with chemicals. Kraft paper is a general name for paper made this way. You see kraft paper in bags, envelopes, and wrapping.

Kraftliner is a special kind of kraft paper. It is thicker and stronger. It is used on the outside of corrugated boxes. Kraftliner often uses more virgin fibers. Kraft paper can use more recycled fibers.

Here is a table to show the differences:

| Property | Kraft Paper | Kraftliner |

| Weight | Lighter | Heavier |

| Stiffness | Less stiff | Generally stiffer |

| Applications | Used for food packaging and more | Used for printing and packaging |

Kraft paper is for lighter jobs. Kraftliner is for jobs that need more strength. Both kraft products resist tearing and can handle some moisture. Kraft paper bends easily, so it comes in many shapes. Kraftliner is more rigid and protects things during shipping.

Note: Both kraft paper and kraftliner can be recycled. Using recycled fibers helps the environment.

Properties of Kraftliner

Strength and Durability

Good packaging needs to be strong. Kraftliner gives you that power. The kraft process makes long, tough fibers. These fibers help kraft paper stay strong. It does not tear or burst easily. When you use kraftliner, your products stay safe. They are protected during shipping and storage.

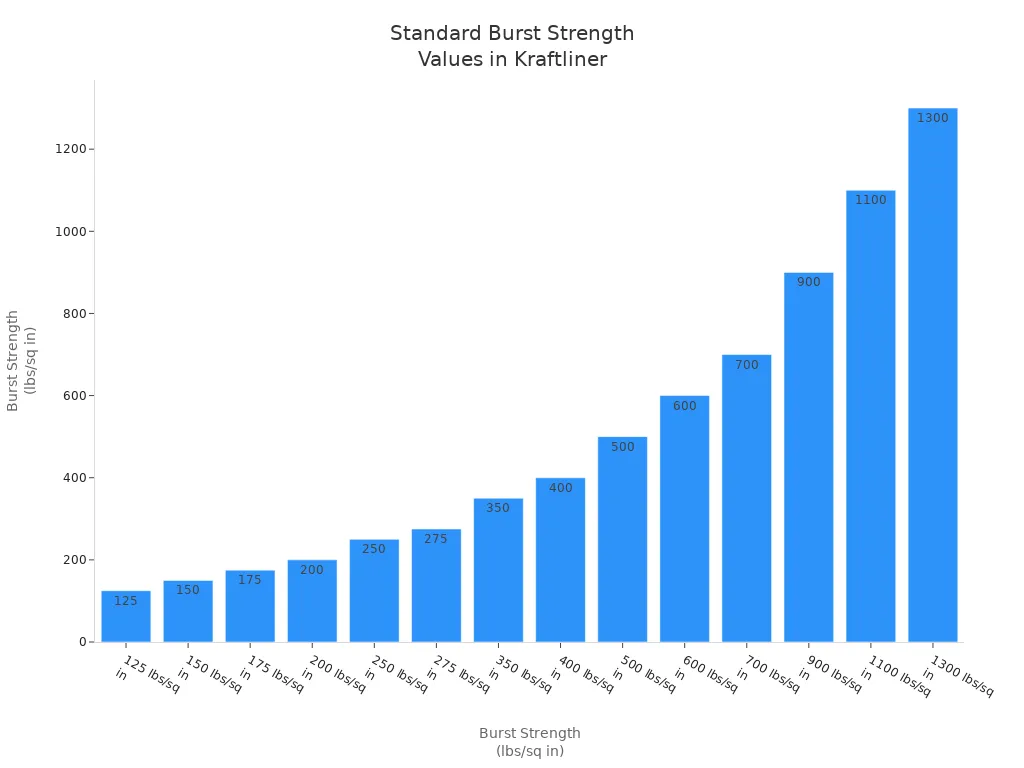

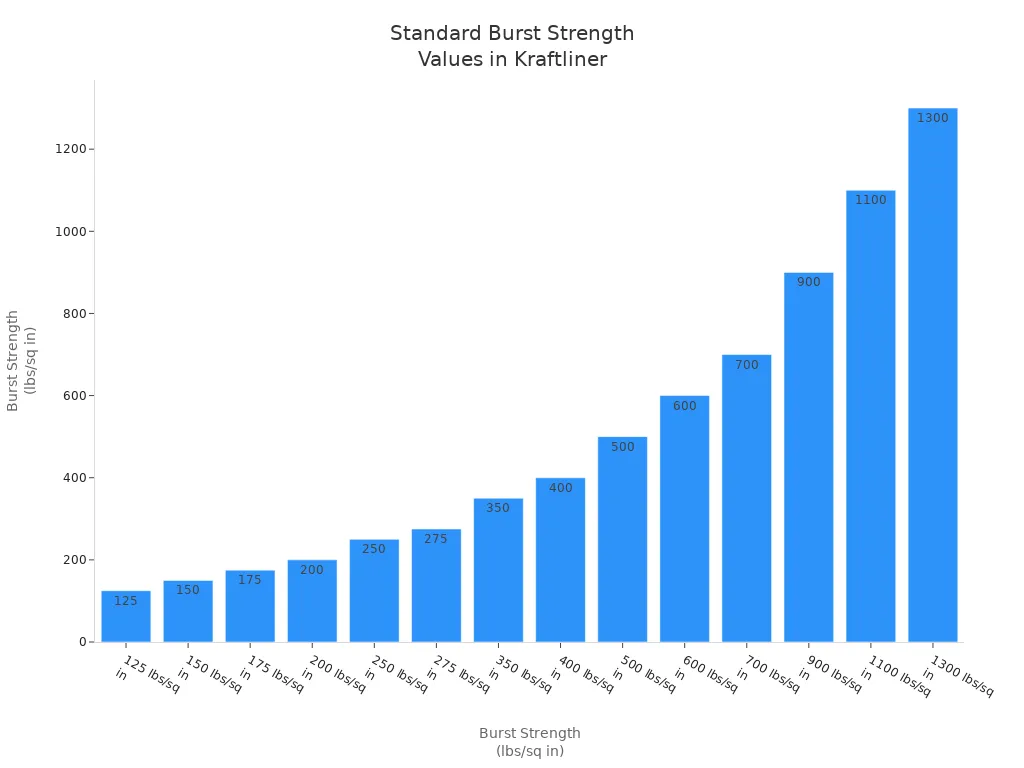

Burst strength shows how much pressure kraftliner can take. If the pressure gets too high, the paper breaks. Here is a table with burst strength numbers for kraftliner:

| Burst Strength (lbs/sq in) |

| 125 |

| 150 |

| 175 |

| 200 |

| 250 |

| 275 |

| 350 |

| 400 |

| 500 |

| 600 |

| 700 |

| 900 |

| 1100 |

| 1300 |

Kraft paper is hard to rip. Your boxes do not break easily. Kraftliner stays strong even when wet. You can trust it in damp places. Other linerboards made from recycled fibers are not as good. Kraftliner is made to resist water. It works well for products that need extra care.

Tip: Pick kraft paper if you need packaging that stays strong.

Versatility and Elasticity

Kraftliner lets you design many kinds of packaging. You can use it for lots of things. Kraft paper works for bags, wraps, and envelopes. Kraftliner is great for boxes, cartons, and displays.

Kraftliner fits many packaging jobs.

You can use it for boxes, cartons, and displays.

It works for products with different shapes.

Kraftliner comes uncoated or coated for special uses.

Kraft paper is recyclable and made from good materials.

Kraft products are tough and last a long time.

Elasticity means kraft paper can bend and flex. It does not break easily. Kraftliner is stiffer but still bends a little. It can take shocks and bumps. This keeps your products safe when shipped. You can use kraft for light or heavy packaging.

Note: Kraft products help the planet because you can recycle them.

Surface and Printability

You want your packaging to look nice. Kraftliner helps with that. The surface of kraft paper is smooth and strong. It is easy to print pictures and words on it. Industry standards for kraftliner focus on strength and print quality. These things matter for fancy packaging.

Special coatings can make printing even better. For example:

Kraftliner gives you a surface that holds ink well. You get bright colors and clear images. Many brands pick kraft paper for packaging that stands out.

Tip: For the best prints, choose kraft products with special surface treatments.

Kraftliner Applications

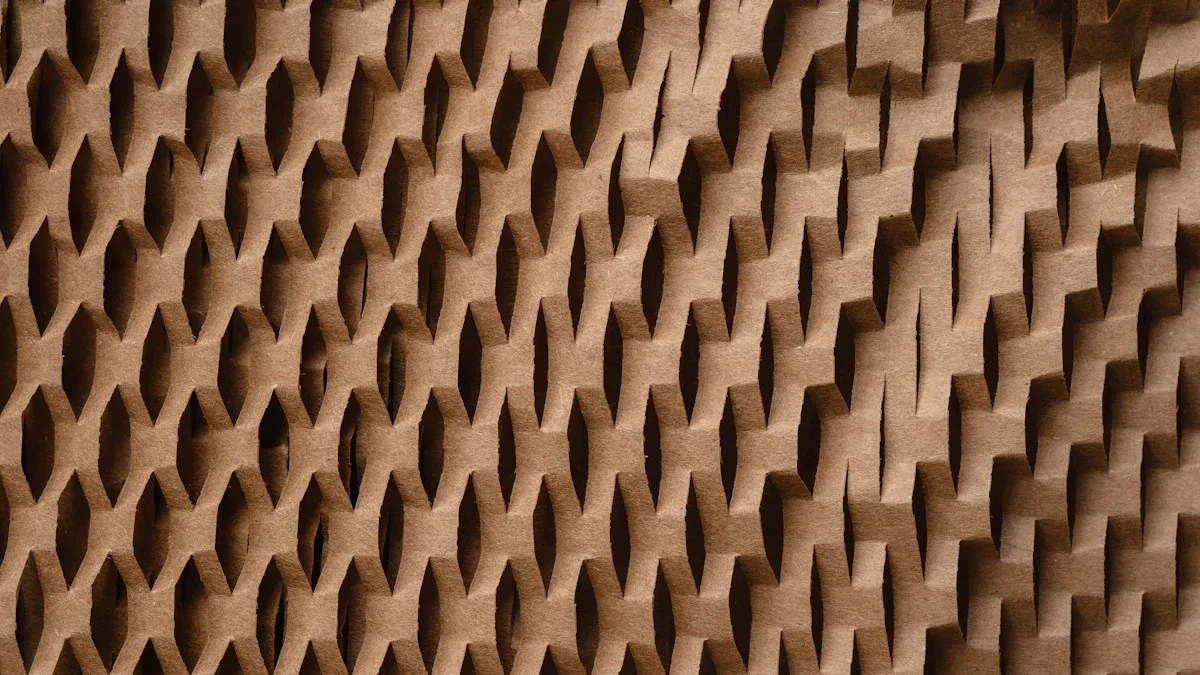

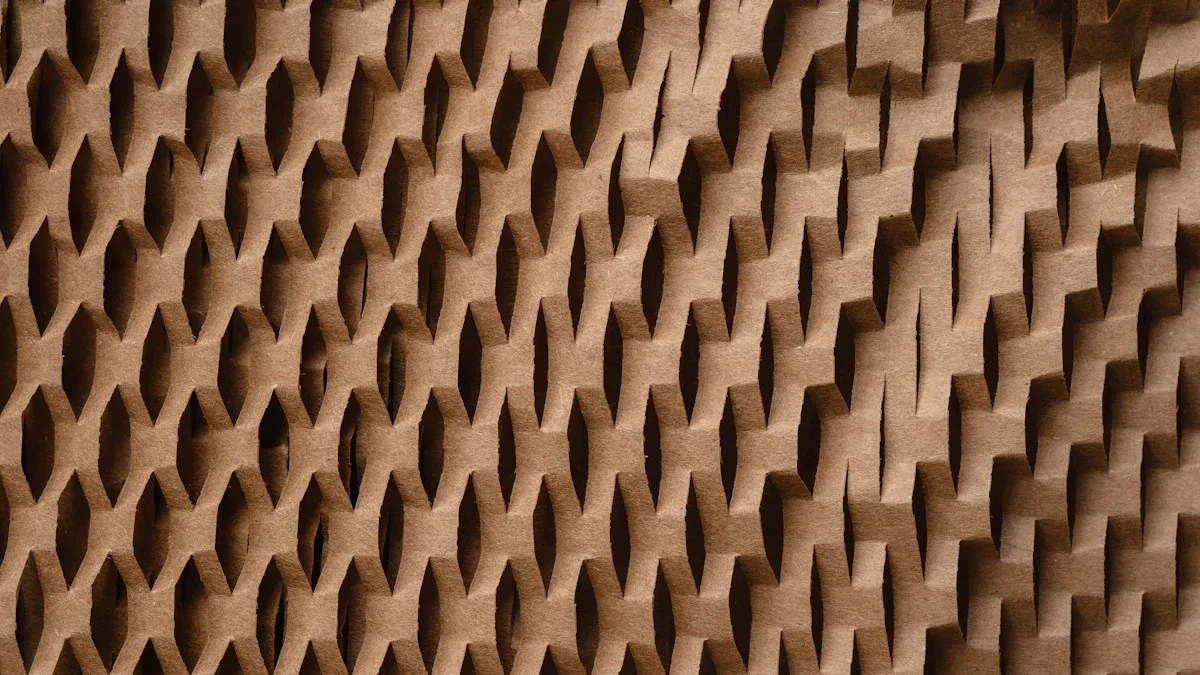

Image Source: pexels

Packaging

Kraft paper packaging is used everywhere. Grocery stores use it for food bags. Bakeries wrap bread in kraft paper. Many companies pick kraft paper because it is strong. It is safe for food. Kraft paper packaging protects snacks and fruits. It also keeps vegetables safe. You can use it for dry goods and frozen foods. Kraft paper packaging works for takeout meals too. It helps keep food fresh.

Kraft paper packaging is good for boxes and cartons. You see it in cereal boxes and cookie packages. Kraft paper packaging does not tear easily. It keeps products safe. Brands print logos and designs on kraft paper packaging. It looks natural and clean. Kraft paper packaging is recyclable. Choosing it helps the planet.

Here is a table that shows why kraftliner is a top choice for packaging:

| Advantage | Description |

| Eco-Friendly and Sustainable | Kraft packaging uses natural materials. It is biodegradable and recyclable. This supports sustainability goals. |

| Strong and Durable | Kraft packaging resists tearing. It is good for heavy or fragile items. It works for many packaging needs. |

| Visually Appealing | Kraft packaging has a brown color and earthy look. It gives a clean style. It fits eco-friendly brands. |

| Lightweight and Cost-Efficient | Kraft packaging is light. It lowers shipping costs. It is easy to handle and customize. |

| Excellent Print Surface | Kraft packaging is great for printing. Brands use it for custom designs and logos. |

Tip: Kraft paper packaging helps you protect products and meet sustainability goals.

Shipping

Kraft paper packaging is important for shipping. It protects heavy and fragile items. Kraft paper packaging does not tear or break easily. It resists water. Kraft paper packaging keeps boxes strong when shipped. It uses long fibers for extra strength. Kraft paper packaging is better than white cardboard for shipping.

Here is a table that compares kraft paper and white cardboard for shipping:

| Property | Kraft Paper | White Cardboard |

| Fiber Length | Kraft paper has longer fibers. | White cardboard has shorter fibers. |

| Durability | Kraft paper is stronger and resists tears. | White cardboard is less durable. |

| Tensile Strength | Kraft paper has high strength. | White cardboard has moderate strength. |

| Bursting Resistance | Kraft paper resists bursting. | White cardboard does not resist bursting as well. |

| Water Resistance | Kraft paper resists water. | White cardboard does not resist water. |

| Suitable for Heavy Cargo | Kraft paper works for heavy cargo. | White cardboard does not work for heavy cargo. |

Kraft paper packaging keeps products safe from drops and bumps. You can use it for shipping electronics, books, and clothes. Kraft paper packaging is the best choice for shipping.

Retail Uses

Stores use kraft paper packaging in many ways. You see it in gift bags and shopping bags. Kraft paper packaging is used for wrapping paper too. It looks natural and fits eco-friendly brands. Stores print logos and messages on kraft paper packaging. It helps products stand out.

Food packaging in stores uses kraft paper for sandwiches and cookies. It is also used for salads. Kraft paper packaging keeps food fresh and safe. It is easy to fold and shape. Stores use it for many things.

Note: Kraft paper packaging helps your brand look clean and green.

Specialty Uses

Kraft paper packaging is used for special jobs. Factories use it for fiber drums. Kraft paper packaging protects heavy materials in tough places. It is used to make tubes for industry. Kraft paper packaging makes cornerboards for boxes.

Here is a table that shows specialty uses for kraft liner:

| Specialty Use | Description |

| Fiber Drums | Kraft packaging is used for heavy materials. It is strong and works in tough conditions. |

| Tubes | Kraft packaging is used for tubes in factories. It protects and gives structure. |

| Cornerboards | Kraft packaging makes cornerboards. These help boxes stay strong during shipping. |

Kraft paper packaging helps many industries. You see it in construction and manufacturing. It is also used in shipping. Kraft paper packaging is strong and flexible. It is good for the environment. Kraft paper packaging protects products and helps with sustainability.

Industry Standards

Quality Benchmarks

It is important to know how kraft paper and kraft liner meet quality rules. These rules help you pick the best packaging for your needs. Different places have their own rules for kraft products. Asia Pacific, North America, and Europe each care about different things. Asia Pacific is growing fast because more people shop online and cities are getting bigger. North America cares about saving nature and new packaging ideas. Europe has strict rules for the environment and wants kraft paper that is good for the planet.

| Region | Key Characteristics | Growth Factors |

| Asia Pacific | Big market share, fast factories, more cities, more online shopping | High growth rate of 5.2%, cares about green packaging, government helps with eco-friendly plans |

| North America | Old packaging industry, cares about saving nature | People know more, rules from the government, new packaging ideas |

| Europe | Follows environment rules, wants green products | Grows a little, better liner quality, uses eco-friendly ways |

These rules decide how kraft paper and kraft liner work in each place.

Testing Methods

Kraft paper and kraft liner need to be strong for shipping and storage. Rules say you must test them for strength and toughness. There are different ways to check kraft products. The Concora Test (CMT) pushes on fluting to see how strong it is. The Ring Crush Test (RCT) bends kraft paper into a ring and checks when it breaks. The Bursting Strength Test (BFT) finds out how much force kraft paper can take before it pops.

| Testing Method | Description |

| Concora Test (CMT) | Pushes on fluting to see board strength, measured in Newton or kgf. |

| Ring Crush Test (RCT) | Bends paper into a ring and pushes until it breaks, measured in Newton or kgf. |

| Bursting Strength Test (BFT) | Checks how strong paper is before it pops, important for shipping, measured in kpam2/g or kgf/cm2. |

These tests help make sure kraft paper is good for packaging and shipping.

Certifications

You want kraft paper and kraft liner to come from good places. Rules include certifications like FSC, PEFC, and SFI. These show kraft products use wood pulp from forests that are taken care of. Companies work with certified suppliers for a long time. All reels have FSC Chain of Custody certification. All paper for packaging is certified by FSC, PEFC, or SFI. Most packaging given to customers meets these rules.

All virgin wood pulp comes from forests that are managed well.

Companies work with FSC and PEFC certified pulp suppliers.

All reels delivered are FSC Chain of Custody certified.

All paper for packaging is certified by FSC, PEFC, or SFI.

Most packaging given to customers is certified by FSC, PEFC, or SFI.

You can trust kraft paper and kraft liner with these certifications. They meet high rules for being good for the planet and quality.

Sustainability

Fiber Sourcing

You help the environment when you pick kraftliner from good sources. Companies use both new and recycled fibers to make kraftliner. Virgin fibers come from forests that are managed well. These forests plant new trees to replace the ones they cut. Recycled fibers come from old boxes and paper. Using both kinds of fibers helps save forests and keeps trash out of landfills.

Here is how companies try to be more sustainable with fiber sourcing:

| Sustainability Initiative | Description |

| Use of Recycled Fibres | Companies use recycled fibers to keep materials in use longer. |

| Virgin Fibres Management | They get virgin fibers from forests that are taken care of. |

| Certification Targets | They want all sites to have chain of custody certification. |

| Transparency | They make sure they can trace where virgin fibers come from. |

| Recycled Paper Usage | They try to use only recycled or certified papers. |

You help nature by picking packaging made from these fibers.

Recycling

Kraftliner is great for the environment because you can recycle it many times. The long fibers in kraftliner keep boxes strong, even after being reused. Recycled paper has to be thicker to be as strong as kraftliner. This means kraftliner works better with less material. By choosing kraftliner, you help the planet by using packaging that lasts longer and saves resources.

| Aspect | Kraftliner | Recycled Paper |

| Performance Requirement | Needs virgin fiber for best results | Must be thicker to be as strong |

| Fiber Length | Long fibers keep it strong | Short fibers get weaker after use |

| Environmental Impact | Uses trees for new fiber | Gets recycled a lot but still needs new fiber |

Tip: You can recycle kraftliner, which helps cut down on waste and supports the earth.

Eco Certifications

Eco certifications show that kraftliner meets high standards for the environment. These labels help you know your packaging comes from good places. The most well-known certifications include:

| Certification Name | Description |

| Ancient and Endangered Forest Friendly | Uses lots of recycled fiber and protects rare forests. |

| Forest Stewardship Council (FSC) certified | Makes sure wood fiber does not come from rare or old forests. |

| Chlorine-free bleaching | Uses safe ways to bleach so the environment is not harmed. |

When you see these labels, you know your packaging helps forests and clean production. Certifications like FSC and PEFC also show companies follow strict rules for making kraftliner. Many people and businesses want these certifications because they care about the earth. You help the planet and earn trust from customers when you pick certified packaging.

Using certified kraftliner shows you care about the environment.

Certifications make your brand look better and help you get loyal customers.

FSC and PEFC labels mean your packaging meets top rules for the environment.

You have learned that kraftliner is strong and lasts long. It is also good for the earth. Here are some tips for picking packaging: 1. Use kraftliner for heavy things, food, or fancy packaging. 2. Choose test liner if you need to save money or pack light items. Rules and laws are changing how kraftliner is made. These rules are important for the future:

| Regulatory Aspect | Impact on Kraftliner Sector |

| Carbon Emission Reduction | Cleaner ways to make kraftliner can cost more money |

| Stricter Recycling Mandates | Companies must recycle better and make greener products |

| Compliance Pressure | Companies work harder on research and team up for green ideas |

Picking kraftliner that is certified and green helps your business and the earth.

FAQ

What makes kraftliner different from other kraft paper types?

Kraftliner is used on the outside of corrugated boxes. Other kraft paper types are for bags or wraps. Kraftliner has strong fibers that make it extra tough. This is why it works well for packaging and shipping heavy things.

How does the global kraft paper market affect corrugated packaging?

The global kraft paper market changes how corrugated packaging looks. When the market gets bigger, you have more choices and better prices. More companies want packaging that is good for the earth and breaks down easily.

Why is sustainability in kraft paper important for the packaging industry?

Sustainability in kraft paper helps protect the earth. It supports recycling and using good sources for materials. Many companies pick kraft paper because it is better for the planet. This helps the kraft paper market grow and reach green goals.

What are the main strategic applications for corrugated kraft packaging?

Corrugated kraft packaging is used for shipping, storage, and store displays. These uses help keep products safe. The market grows because this packaging is strong, can be recycled, and fits many needs.

How do kraft paper market trends impact sustainability in kraft paper?

Trends in the kraft paper market make people choose greener options. You see more products that break down and use recycled materials. These trends help kraft paper stay strong and support a healthy planet. By picking green packaging, you help shape the future.