Types of specialty papers might sound niche, but they shape everything from receipts to luxury packaging. Ever wondered why some paper fades fast while others last for years? It often comes down to choosing the right paper type for the job.

In this post, you’ll learn what specialty paper is, why it matters in printing, labeling, and documentation, and how to select the best type for your needs. We’ll cover thermal, carbonless, coated, synthetic, and more—all explained simply.

What Makes Paper “Specialty”?

Key Features of Specialty Paper

Enhanced Performance

Specialty paper often outlasts standard types. It resists tearing, moisture, smudging, and even high temperatures. Many are designed to work perfectly with thermal printers, dot matrix systems, or pressure-based processes.

Common examples of performance-based enhancements:

| Feature | Benefit | Common Use Cases |

| Tear resistance | Prevents damage during handling | Labels, shipping tags |

| Heat sensitivity | Reacts to heat instead of ink | Thermal receipts, tickets |

| Smudge-free surface | Keeps prints clean and legible | Legal forms, reports |

Unique Finishes and Textures

You can feel the difference. Specialty paper might have a high-gloss shine, a soft matte surface, or a textured grain that gives it a premium touch or practical function.

Glossy finishes help colors pop in labels or brochures.

Textured paper enhances grip or adds a decorative edge.

Matte surfaces reduce glare and improve readability.

Chemical Coatings or Treatments

These coatings do more than protect—they transform how the paper works.

Thermal Coating

Used in thermal printers. Turns black when exposed to heat, no ink needed.

Microencapsulation

Tiny dye capsules burst under pressure to create carbonless copies.

Water- or grease-resistant layers

Used in packaging, they help keep printed information readable under messy conditions.

How Specialty Papers Differ from Standard Papers

Composition and Layering

Comparison Table: Standard vs. Specialty Paper

| Feature | Standard Paper | Specialty Paper |

| Layers | Single-layer | Multi-layer or coated |

| Durability | Moderate | Often high (tear, heat, smudge resistant) |

| Printing Method | Ink-based | Thermal, impact, or special coating |

| Function | General use | Tailored (e.g., receipts, labels, forms) |

Functional vs Decorative Use

Functional papers help complete tasks—like creating duplicate copies without ink or printing durable tickets.

Decorative papers add beauty through texture, sheen, or color—but may still have practical properties like print compatibility.

Categories of Specialty Papers

Thermal Paper

What is Thermal Paper?

Thermal paper is a special type of paper coated with heat-sensitive chemicals. It changes color when exposed to heat during printing.

How It Works

It has a surface coated with a material that reacts when exposed to heat, producing images or text without using ink.

Thermal printers use a heated printhead to selectively apply heat, creating darkened areas where contact occurs.

Since no ribbons or toner are involved, it's often used in compact or portable printing systems.

Common Uses

It's commonly used in point-of-sale (POS) systems for receipts due to its speed and convenience.

Shipping and barcode labels are often printed on thermal paper because it doesn't require ink or toner refills.

Transit and event tickets rely on thermal paper for fast, cost-effective, and on-demand printing.

Advantages and Disadvantages

| Advantages | Disadvantages |

| Fast, quiet printing process | Content may fade quickly over time |

| No ink or ribbon required | Sensitive to light, heat, and friction |

| Low maintenance costs | Not suitable for archival storage |

Carbonless Paper (NCR Paper)

What is Carbonless Copy Paper?

Carbonless copy paper creates duplicate copies without using carbon sheets. It reacts to pressure, making it useful for multi-part forms.

How It Works

Each sheet is coated with microcapsules containing dye or ink that rupture under pressure and transfer to the sheet below.

Typically, the back of the top sheet and the front of the next sheet have coatings that interact when written on.

This layered structure allows multiple copies to be created from a single written original, with no separate carbon sheet.

Applications

Frequently used for invoices and receipts that need to be handed out to multiple parties in one writing.

Business order forms rely on carbonless paper to keep an internal record and provide a customer copy instantly.

Delivery or service documents often include carbonless layers to track signature or inspection across departments.

Comparison with Traditional Carbon Paper

| Feature | Carbonless Paper | Traditional Carbon Paper |

| Clean and mess-free | Yes | No, leaves carbon residue |

| Number of copy layers | Supports up to 5 or 6 layers | Typically only 1 or 2 layers |

| Environmental impact | Recyclable and non-toxic | Often uses dye that isn’t clean |

Coated Paper

Glossy, Matte, and Silk Coatings

Glossy coated paper offers vibrant colors and high contrast, ideal for detailed images or photographic prints.

Matte paper provides a smooth, non-reflective finish that reduces glare and is easier to read under light.

Silk coating delivers a soft texture that sits between glossy and matte, suitable for elegant visuals without excessive shine.

Ideal for High-Quality Image Printing

These papers hold ink on the surface, preventing absorption and allowing for sharper image reproduction.

They're often chosen for printing jobs where detail, color fidelity, and texture are important to the final result.

Graphic designers prefer coated paper for marketing materials due to its ability to maintain color consistency.

Common Uses

Used for corporate brochures to ensure branding appears sharp and professional.

Magazines rely on coated paper to highlight photos, headlines, and editorial layouts with clarity.

Marketing flyers and product catalogs use it to present product images with vibrant, true-to-life quality.

Security Paper

Designed to Prevent Forgery or Tampering

Security paper includes features that help verify authenticity and prevent duplication or tampering of important documents.

Features

Built-in watermarks that become visible when held against the light, deterring unauthorized reproduction.

Microtext printed with tiny fonts, legible only under magnification, helps prevent photocopy or scan-based fraud.

Some papers use color-changing inks that shift appearance based on angle or temperature for added verification.

Applications

Frequently used in financial documents such as checks to guard against fraud and alterations.

Certificates and diplomas are printed on security paper to ensure authenticity and prevent counterfeiting.

Legal contracts may include tamper-evident elements embedded within the paper to show signs of alteration.

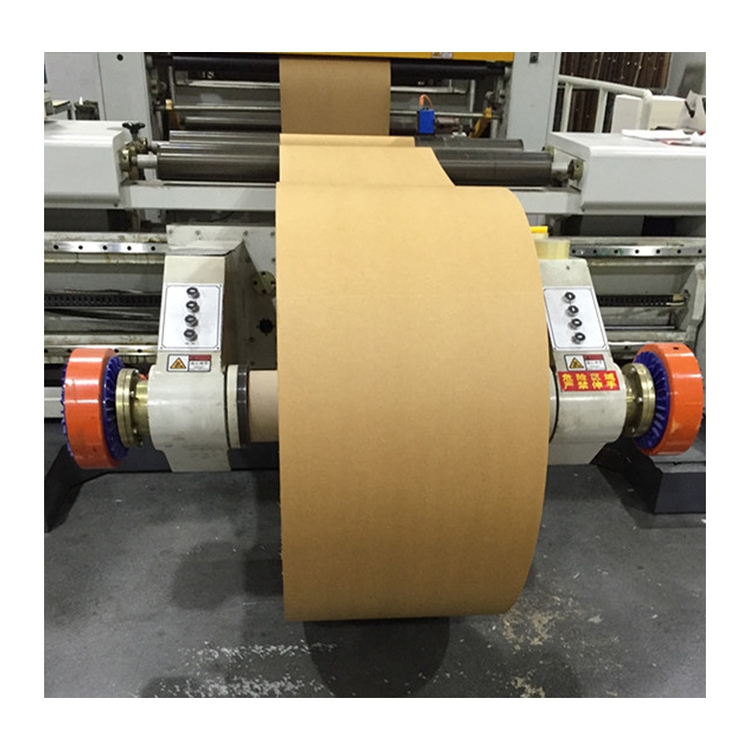

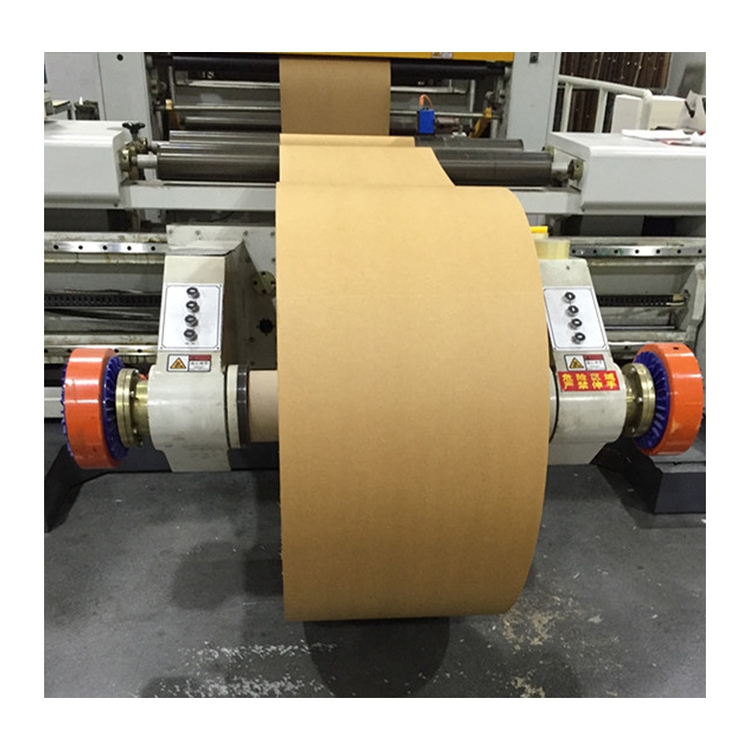

Kraft Paper

Unbleached, Durable, and Recyclable

Kraft paper is made using the kraft pulping process, giving it strength, a natural brown color, and a coarse texture ideal for packaging.

Common Uses

Widely used for wrapping heavy items during shipping because it resists tearing and punctures well.

Grocery bags and industrial sacks are often made of kraft paper due to its load-bearing capability.

It’s a favorite for DIY projects and craft work because of its natural look and flexibility.

Specialty Forms

Bleached Kraft paper is white, offering a cleaner look while retaining strength and environmental benefits.

Wax-Coated Kraft provides a moisture-resistant barrier, making it ideal for food wrapping or cold storage.

Synthetic Paper

Made from Plastic Resins

Synthetic paper is crafted from polypropylene or polyethylene, offering the appearance of paper with the durability of plastic.

Water-Proof, Tear-Resistant, and Durable

It withstands water exposure without smudging or deteriorating, making it suitable for outdoor use.

Unlike traditional paper, it resists tearing and performs well in high-stress environments.

Its durability makes it ideal for printing that must endure rough handling or extreme conditions.

Ideal for Labels, ID Cards, and Outdoor Signage

Product labels that face moisture or friction benefit from synthetic paper's resilience and printability.

ID cards, membership tags, and key cards often use synthetic materials to increase lifespan and durability.

Outdoor signage relies on synthetic paper to remain readable and intact in variable weather conditions.

Parchment and Vellum Paper

Translucent or Antique-Style Specialty Papers

These papers offer unique textures and visual appeal. They’re typically used for special occasions or decorative purposes.

Popular Uses

Invitations for weddings and events often use vellum or parchment to give an elegant, vintage feel.

Baking sheets and food wrapping sometimes use food-grade parchment due to its non-stick, heat-resistant qualities.

Crafts like calligraphy, scrapbooking, or decorative overlays benefit from their semi-transparent look.

Pressure-Sensitive Label Paper

Includes Adhesive Backing

This paper has a pre-applied adhesive that activates under pressure, allowing quick and mess-free application.

Used in Stickers, Labels, Product Tags

It’s widely used in packaging labels for retail, shipping, and inventory control across various industries.

Stickers for branding or promotional campaigns are often made from pressure-sensitive materials for easy peeling.

Price tags and barcoded product IDs rely on this type of paper for quick attachment during production.

Available in Removable and Permanent Formats

Removable types can be peeled off without leaving residue, ideal for temporary labels or repositioning.

Permanent adhesives offer long-term adhesion, ensuring labels stay in place through storage, transit, or handling.

Metallic and Pearlized Paper

Specialty Coatings for Decorative Shine

These papers feature reflective or shimmering finishes, making them ideal for premium presentation and high-impact visuals.

Often Used in Luxury Packaging and Premium Stationery

High-end gift boxes and retail packaging use metallic finishes to convey elegance and exclusivity.

Stationery for formal events or special announcements benefits from the visual appeal of pearlized textures.

Business cards and invitations use metallic paper for accents that catch the eye and feel luxurious in hand.

Specialty Paper by Application Area

Specialty Paper for Printing

Specialty paper is designed for high-quality printing. It ensures vibrant colors and sharp details. Laser printers work best with smooth paper, while inkjet printers need slightly textured paper to avoid smudging. The right paper improves print quality, making your projects stand out.

Specialty Paper for Packaging

Packaging papers need strength and durability. They should withstand transport and meet safety standards, especially for food. Kraft paper is sturdy, greaseproof paper prevents oil leaks, and wax-coated paper provides moisture resistance, making it perfect for food packaging.

Specialty Paper for Office and Industrial Use

Specialty paper serves many office and industrial needs, like multi-part forms and thermal rolls. Multi-part forms are great for receipts, while thermal rolls are common in point-of-sale printers. Durable labels ensure products are identified correctly, even in harsh conditions.

Specialty Paper for Arts, Crafts, and Stationery

Specialty paper adds texture and charm to creative projects. Handmade paper works well for custom stationery, while textured cardstock is perfect for arts and crafts. Decorative sheets with patterns or embossing elevate designs, giving them a unique, high-quality look.

Factors to Consider When Choosing a Specialty Paper

Print Technology Compatibility

Different printers need different paper types. Thermal paper works best for point-of-sale printers, while inkjet and laser printers require smooth or textured paper. Dot matrix printers need thicker paper to withstand impact. Choose the right paper for your printer to get the best results.

Durability and Storage Requirements

Durability is important. Some papers need to resist fading, moisture, or physical wear. If storing documents long-term, choose papers with longer shelf lives. They’re perfect for legal or archival documents that need to last without degrading over time.

Cost and Efficiency

Specialty paper can be more expensive, but bulk purchases often reduce costs. Consider the overall lifecycle of paper to determine cost efficiency. Efficient use helps reduce waste, making it a more cost-effective choice for industries that print frequently.

Legal or Industry Requirements

Certain industries have strict paper requirements. Banking, medical, and shipping sectors often require specific paper types for records or receipts. These papers must meet regulatory standards, including durability and security features, to ensure compliance and proper document handling.

Specialty Paper vs Standard Paper: A Comparison

Performance

Specialty paper provides better ink absorption and durability, ensuring long-lasting results. Standard paper tends to wear out quickly and may not hold ink as well.

Cost-efficiency

Specialty paper costs more but can save money in the long term by reducing the need for reprints. Standard paper is cheaper but may require frequent replacements.

Printing Method Compatibility

Specialty paper is designed for specific printers, delivering better quality. Standard paper is more versatile but may not perform well in specialized printing processes.

Visual and Tactile Quality

Specialty paper offers unique textures and finishes for a premium look and feel. Standard paper lacks these features, providing only a basic appearance and touch.

Common Myths About Specialty Paper

“All thermal paper is the same”

Not all thermal paper is identical. It comes in various types, each suited for specific printers and uses. Some are designed for short-term use, while others are more durable, resistant to fading, and suitable for archival purposes.

“Carbonless paper contains carbon”

Despite the name, carbonless paper does not contain carbon. Instead, it uses a chemical coating that reacts under pressure to create a copy of the original document. This process eliminates the need for traditional carbon sheets.

“Specialty paper is always expensive”

While some specialty papers can be costly, not all of them are. Many affordable options exist that offer unique features, like durability or texture, without breaking the bank. The price often depends on the paper's specific use and quality.

Tips for Storing and Handling Specialty Papers

Avoid Heat (for Thermal)

Thermal paper fades with heat. Store it in cool, dry places, away from sunlight or heat sources to prevent damage.

Prevent Moisture (for Synthetic and Coated)

Keep synthetic and coated papers dry. Store them in airtight containers or use desiccants to avoid warping or smearing.

Storage for Long-term Use

To preserve paper, store it in stable, temperature-controlled environments. Avoid high humidity to maintain legibility and quality.

Conclusion

Specialty papers, such as thermal, carbonless, and security papers, offer unique benefits like durability and print compatibility. Choosing the right type based on application—whether for printing, packaging, or documentation—is crucial to achieving optimal results. Experimenting with different specialty papers can enhance the overall quality of your projects.

Selecting the appropriate specialty paper ensures the success of various tasks, from business forms to creative projects. Exploring these options will allow you to make informed choices and elevate the quality of your work, whether in the office or in artistic endeavors. Don’t hesitate to try out different types!

FAQ

What is the difference between carbonless paper and thermal paper?

Carbonless paper uses a chemical coating to transfer impressions, while thermal paper uses heat to create prints.

Can specialty paper be used in regular home or office printers?

Yes, most specialty papers work in standard printers, but it's important to check compatibility for optimal results.

Does specialty paper expire or go bad over time?

Specialty paper can degrade over time, especially thermal paper, which can fade when exposed to heat or light.

Reference Sources

[1] https://www.rppaperimpex.com/types-of-specialty-papers/

[2] https://ediconpaperproduct.com/blog-details/specialty-paper-types-uses-from-packaging-to-printing

[3] https://packsolo.com/what-is-specialty-paper/

[4] https://www.bookprintingchina.com/support/paper-types-and-weight/special-paper

[5] https://paperworld.in/Speciality-Paper.php

[6] https://paperwishes.com/specialty-papers.html