You can see kraft paper in many places. It has a special job in insulation today. People use kraft paper because it is strong and good for the environment. It helps stop heat, electricity, and water from passing through. Many experts choose insulating kraft paper. It can handle heat and pressure. It stays strong and does not let water in. The market for electrical grade kraft paper is growing fast. It is worth $1.2 billion in 2024. It may reach $2.0 billion by 2033.

| Aspect | Data / Insight |

| Electrical Grade Kraft Paper Market Size | USD 1.2 billion in 2024 |

| Projected Market Size | USD 2.0 billion by 2033 |

| CAGR (2026-2033) | 7.0% |

| Growth Drivers | Demand from renewable energy, smart grid infrastructure, electrical insulation needs |

You can find paper insulation in many places. It is used in electrical work and building materials. Insulating kraft paper is strong and easy to use. It is also good for the environment. This makes it a great choice for insulation today.

Key Takeaways

Kraft paper is strong and good for the environment. It stops heat, electricity, and water from passing through. This makes it a great choice for insulation. It gives good electrical safety because it has strong dielectric strength. This helps protect wires and transformers from getting hurt. Kraft paper insulation does not cost much and is simple to put in. This helps save money on supplies and work. Keep kraft paper dry and put it on the warm side of walls. This keeps it strong and stops mold from growing. This useful material works in electrical systems, building insulation, packaging, soundproofing, and other uses.

What Is Kraft Paper?

Composition

You might wonder what makes kraft paper special for insulation. This paper comes mainly from natural fibers. Manufacturers use kraft paper pulp, which is soft and strong. Most kraft paper for insulation contains at least 80% sulfate wood pulp. This high amount of sulfate pulp gives the paper its rough texture and great strength. When you look at electrical grade kraft paper, you find it uses 100% unbleached sulfate wood pulp. This type of pulp is pure and strong. It also gives the paper excellent electrical properties. Sometimes, makers add cotton to the mix. This helps the paper bend better and improves its strength. The main chemical in kraft paper is cellulose. Cellulose comes from wood pulp and gives the paper its structure. Some kraft papers also get special chemicals. These chemicals help the paper last longer and resist heat.

Tip: The high cellulose content in kraft paper helps it block electricity and heat, making it perfect for insulation.

Manufacturing Process

The process to make kraft paper for insulation has several steps. Each step helps the paper work better as an insulator.

You start with unbleached softwood kraft pulp. Workers remove some lignin and hemicellulose. This leaves mostly cellulose, which is key for insulation.

The pulp goes through a drying process. In many cases, vapor phase drying is used. This step changes the cellulose fibers. The fibers become stiffer and stronger.

During drying, the fibers lose water. This causes the fibers to crosslink and shrink. The paper becomes less flexible but much stronger.

The cell walls in the fibers collapse a bit. This change helps the paper resist breaking and improves its ability to block electricity.

The strength and aging of the paper depend on how well the fibers are dried and linked. Good drying means the paper will last longer and work better as insulation.

You can see that each step in making kraft paper changes its structure. These changes help the paper stay strong and safe in tough conditions.

Properties of Insulating Kraft Paper

When people pick insulation for buildings or electrical work, they want it to be tough. It should handle heat, stress, and wetness. The main features of insulating kraft paper make it a favorite for many jobs. Let’s look at these important traits.

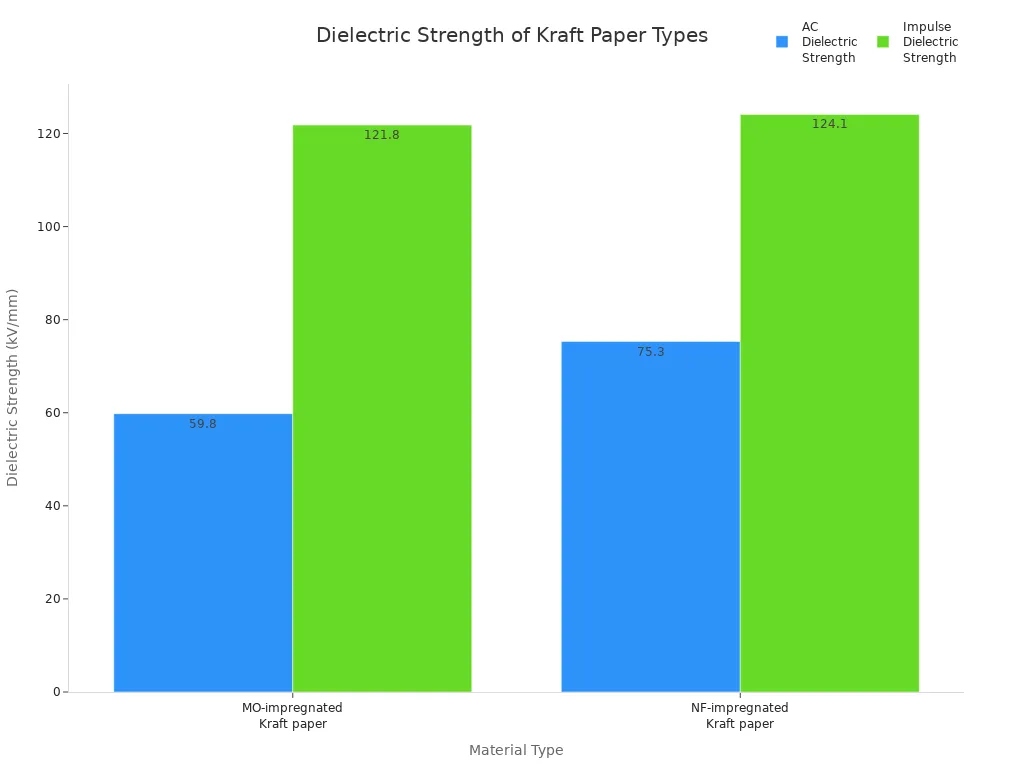

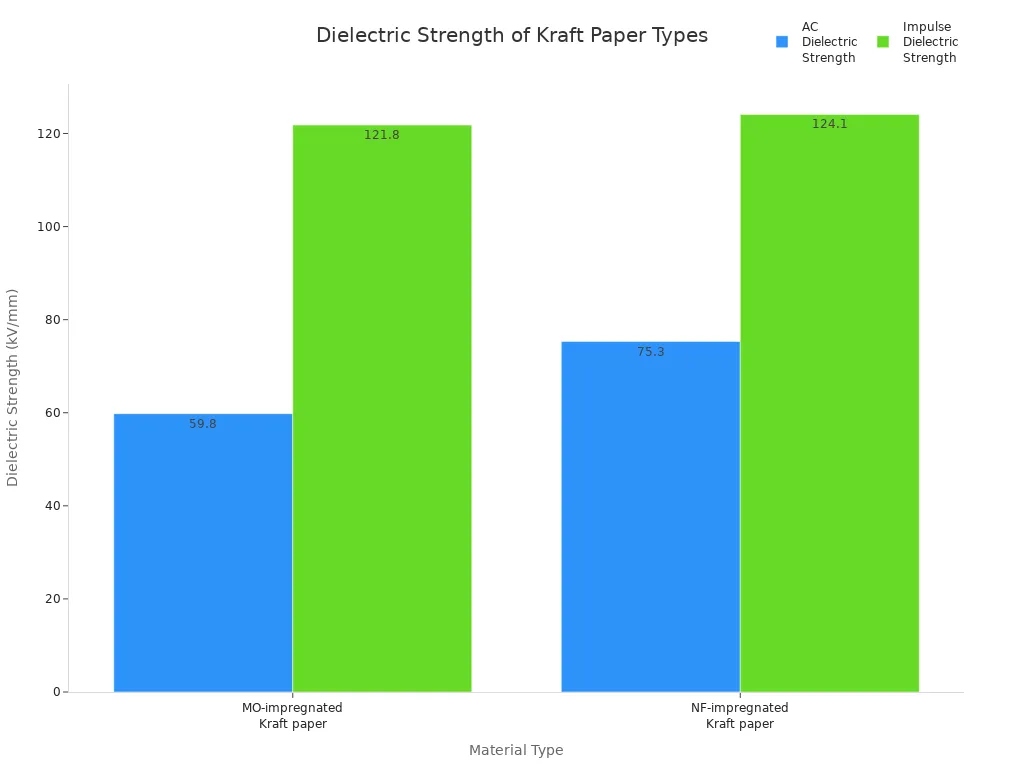

Dielectric Strength

Dielectric strength shows how well something stops electricity. This is very important for electrical insulation. Insulating kraft paper is great because it can handle high voltage. It does not break down easily. If you soak kraft paper in mineral oil, it can reach about 60 kV per millimeter. If you use kraft paper with special nanofluid, it goes up to about 75 kV per millimeter. This means the paper blocks even more electricity. It helps keep electrical equipment safe.

Here is a table that compares the dielectric strength of different types of kraft paper:

| Material Type | Dielectric Strength (AC, kV/mm) | Dielectric Strength (Impulse, kV/mm) | Notes on Comparison and Improvement |

| MO-impregnated Kraft paper | 59.8 ± 0.4 | 121.8 ± 7.45 | Baseline Kraft paper dielectric strength impregnated with mineral oil |

| NF-impregnated Kraft paper | 75.3 ± 0.7 | 124.1 ± 8 | Shows ~26% improvement in AC dielectric strength over MO; slight increase in impulse strength |

| Weibull Scale Parameter (a) | 69.2 (MO) / 79.7 (NF) | N/A | Confirms higher dielectric strength and less variability for NF-impregnated samples |

| Weibull Shape Parameter (b) | 6.5 (MO) / 11.7 (NF) | N/A | Indicates less scatter in NF-impregnated samples |

You can see that insulating kraft paper works very well in electrical systems. Its high dielectric strength keeps wires and transformers safe from short circuits.

Mechanical Durability

Insulation needs to last and handle being moved or bent. Kraft paper is very strong. The cellulose fibers help it resist tearing. You can bend or wrap the paper around wires and it will not break. Many engineers trust kraft pulp insulation paper. It keeps its shape and strength for many years.

Note: Strong insulation means you do not need to fix or replace it often.

Thermal Stability

Insulating kraft paper must also handle heat. It is often close to hot wires or coils. Kraft paper works well up to about 110°C. If it gets hotter, the paper starts to break down faster. At 120°C, it loses strength. At 150°C or more, the paper breaks down quickly and may fail. Experts say to keep the temperature below 110°C so the insulation lasts longer.

Tests show water leaves the paper at about 80°C. Oxidation, which hurts the paper, starts at 150°C. At 200°C, the paper loses a lot of mass. It cannot protect against heat or electricity anymore. Always check the temperature limits when using kraft paper for insulation.

Moisture Resistance

Water can cause problems for insulation. Kraft paper can resist water a little, but it can still soak up moisture from the air. When this happens, the paper changes shape and gets weaker. Water moves through tiny holes in the paper, not through the fibers. This can make the paper swell or shrink. It can hurt how well the paper insulates.

When kraft paper gets wet, heat passes through it more easily. The insulation does not work as well. In very humid places, the paper may lose much of its power to insulate. You should keep kraft paper dry. Use coatings or barriers if you need extra protection.

Tip: Always keep kraft paper insulation dry so it works its best.

Benefits

Cost-Effectiveness

You want insulation that works well and does not cost much. Paper insulation is one of the cheapest choices. When you look at kraft paper faced fiberglass, it costs less than many other materials. Fiberglass insulation is about $0.40 for each square foot. Spray foam can cost up to $3 for the same size. Foam board insulation is also more expensive than fiberglass. Kraft paper faced fiberglass is as cheap as unfaced fiberglass. This makes it a good pick for lots of projects. You can put it in by yourself, so you save even more money. These reasons show why paper insulation gives good results without costing a lot.

Environmental Sustainability

If you care about the earth, kraft paper insulation is a great choice. This material breaks down fast and does not last for years like plastic. You can recycle kraft paper many times before it gets too weak. Recycling kraft paper uses less energy than making plastic. This helps lower pollution. Kraft paper comes from wood pulp in forests that are grown back. Making kraft paper uses fewer chemicals and less energy than making fake materials. Leftover parts from making kraft paper often get used again, so there is less waste. These facts show why using paper insulation helps make the world greener.

Using paper insulation is a smart and earth-friendly way to keep your home safe.

Versatility

You can use insulating kraft paper in lots of ways. In electrical work, it goes around wires, inside transformers, and in motors. It also works in capacitors. In packaging, kraft paper is used for grocery bags, shipping boxes, and wrapping food. For crafts, you use it in scrapbooks, cards, and art. In building, paper insulation helps with roofs and keeps out water. These uses show why paper insulation is helpful in many jobs. Kraft paper insulation fits many needs, like keeping wires safe or food fresh. The many uses of kraft paper insulation make it a top pick for workers and people who do projects at home.

Applications of Paper Insulation

Paper insulation is important in many jobs. You see it in electrical work, building, packaging, soundproofing, and construction. Let’s check out how insulating kraft paper helps in each area.

Electrical Insulation

Paper insulation is used a lot in electrical gear. It keeps wires, busbars, and bushings safe from short circuits. In power transformers, you need insulation that can handle heat and high voltage. Paper insulation wraps around coils and windings to protect them. It is also found in high-voltage cables to stop electricity from leaking. Factories use insulation paper for busbars and bushings because it is strong and bends easily.

You can count on paper insulation to keep electrical systems safe.

Some main uses are:

Wrapping coils in transformers

Insulating busbars and bushings in switchgear

Lining high-voltage power cables

Paper blocks electricity and stands up to heat. This helps your equipment last longer and lowers the chance of problems.

Thermal Insulation

Paper insulation helps control heat in buildings. It keeps rooms warm in winter and cool in summer. It works by trapping air and slowing heat movement. You can put it in walls, attics, and floors. This saves energy and makes your home more comfy.

Sometimes, paper insulation is used with fiberglass. The paper acts as a vapor barrier to stop moisture from getting in. This keeps the insulation dry and working well. You can trust paper insulation to give strong thermal protection in many projects.

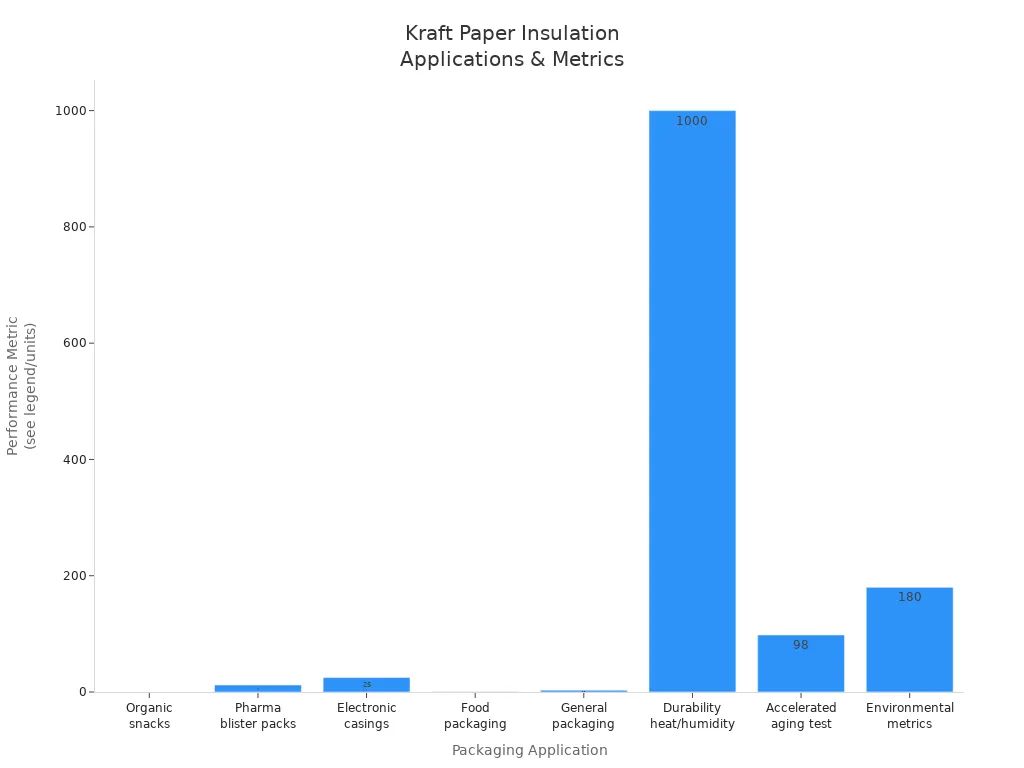

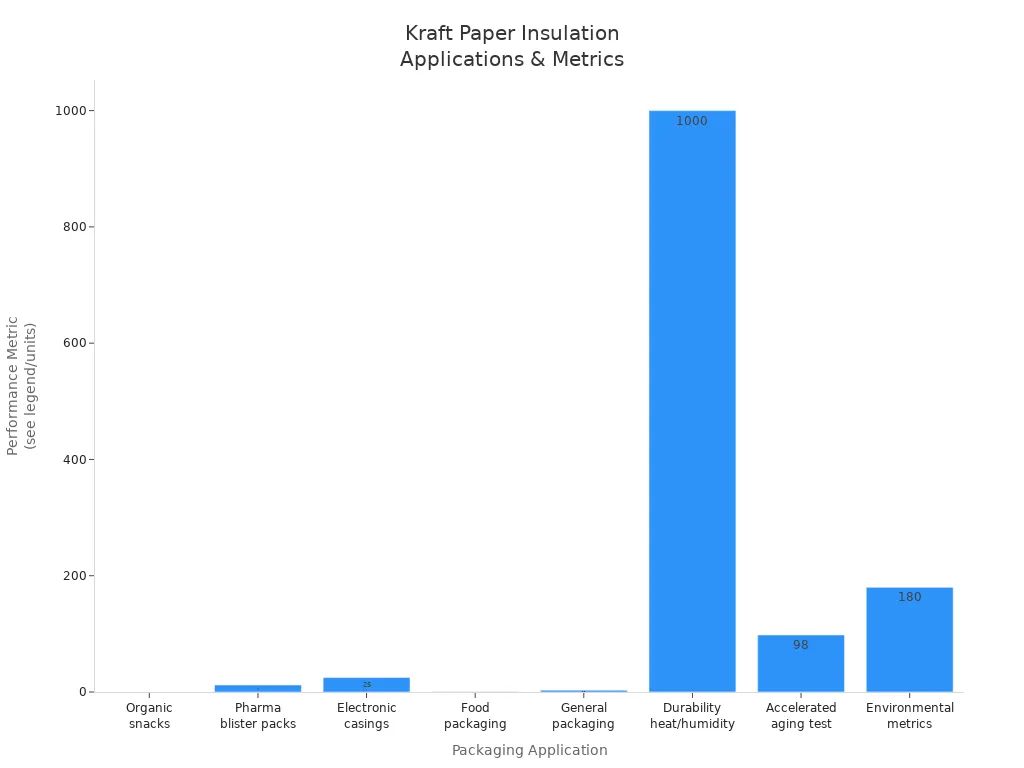

Packaging

Paper insulation is used in lots of packaging. It protects food, electronics, and medicine during shipping and storage. You might see it with snacks, medicine packs, and electronic parts. The table below shows how paper insulation works in different packaging:

| Packaging Application | Performance Metrics / Properties | Description / Impact |

| Organic snacks (premium packaging) | Oxygen transmission rate <0.1 cc/m²·day | Extends shelf life by 40% compared to plastic-only packaging |

| Pharmaceutical blister packs | Puncture resistance: 12N | Prevents accidental tearing, protects sterile medications |

| Electronic component casings | Dielectric strength: 25 kV/mm | Protects against electrostatic discharge, reduces component failure by 18% |

| Food packaging (baked goods, snacks) | Moisture resistance (water vapor transmission rate <0.3 g/m²·day) | Suitable for direct food contact, meets FDA and EU food safety standards |

| General packaging | Tensile bonding strength: up to 3.2 N/15mm | 50% higher than industry standards, remains intact after 500 flex cycles |

| Durability under heat and humidity | No delamination after 1000 hours at 60°C; zero bubbles after 30 days at 95% humidity | Ensures packaging integrity in extreme conditions |

| Accelerated aging test | 98% integrity after 6 months at 40°C/75% RH | Demonstrates long-term stability for pharmaceutical packaging |

| Environmental metrics | Biodegradable within 180 days; 35% lower carbon footprint vs PET-aluminum composites | Supports sustainability and eco-friendly packaging goals |

You can use paper insulation for:

Paper bags, cartons, and pouches

Corrugated boxes for heavy things

Folding cartons for gifts and makeup

Paper insulation gives you strong, safe, and earth-friendly packaging. It keeps your products safe and helps your brand.

Soundproofing

Paper insulation helps control noise in homes, offices, and factories. It soaks up sound waves and cuts down on echoes. You see it in wall panels, ceilings, and floors. Paper insulation helps lower noise from outside or between rooms.

When you compare it to wool, you see some differences. Wool soaks up sound well and helps with fire safety and air quality. Paper insulation focuses on sound and basic insulation. You can make paper panels thicker or change their shape to block more sound.

| Aspect | Kraft Paper/Cardboard-based Soundproofing | Specialized Acoustic Materials (e.g., mineral wool, polyester fibers) |

| Acoustic Performance | Can be engineered as sound-absorbing panels with competitive performance; influenced by thickness, layering, and cavity resonance effects | Generally high performance with additional multifunctional properties |

| Environmental Impact | Lower embodied energy; recyclable; sustainable alternative; supported by LCA showing reduced environmental impacts | Often higher embodied energy; may have higher environmental footprint |

| Additional Properties | Primarily sound absorption and insulation; may lack fire resistance and biodegradability | Often biodegradable, fire resistant, and improve indoor air quality |

| Historical and Research Context | Patents since 1930s; recent EU-funded research on sustainable noise absorption materials | Well-established in construction and industrial use |

| Design Flexibility | Can be optimized via hole diameter, shape, and plenum thickness to enhance sound absorption | Typically standardized products with known acoustic properties |

You can use paper insulation to help make spaces quieter. It is a green way to cut down noise in many places.

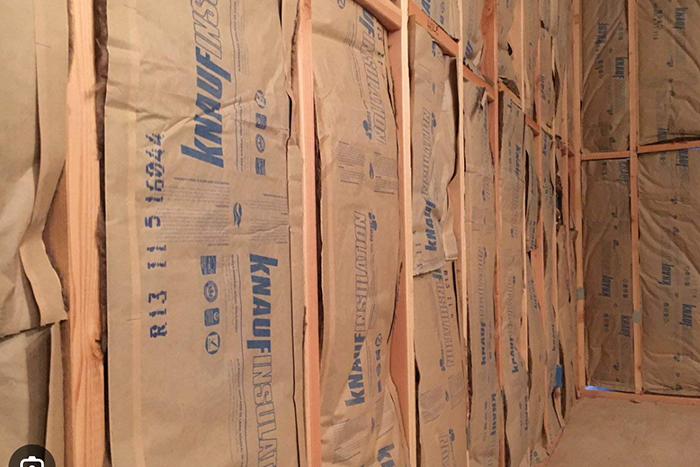

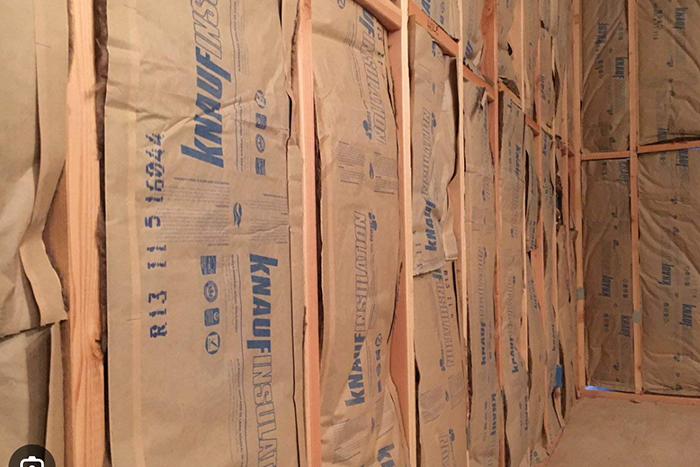

Construction

Paper insulation is used in building to control moisture, air, and temperature. It is often found as a facing on fiberglass batts. You put it on the warm side of walls to act as a vapor retarder. This stops moisture from getting in and causing mold.

Always put the paper facing toward the warm side of the wall. This helps it work as a vapor barrier.

You need to staple the paper tightly to the studs. Do not leave gaps or tears, or moisture can get in and hurt the insulation. Some building codes say you must use paper insulation as a vapor barrier. You also see it in roofs and floors to meet energy rules.

You can find paper insulation in:

Walls as a vapor retarder

Roofs and attics for thermal insulation

Floors to block moisture and air

Using paper insulation the right way gives you a safer and more comfy home.

Types and Grades

Electrical Grade Kraft Paper

Not all insulation paper works the same way. Electrical grade kraft paper is made from strong wood pulp. This makes it very tough and hard to rip. It is used to block high electrical voltages. People use it to wrap electric cables in home appliances. You also find it in transformers and power cables. Its main benefit is high dielectric strength. This means it stops electricity from passing through. That keeps your equipment safe.

Some insulation paper, like insulating crepe paper, is made differently. Makers crinkle the electrical grade kraft paper. This makes it bendy and even stronger. The creping process helps the paper resist rips and holes. It still keeps its great dielectric strength and handles heat well. You can use this type for hard electrical jobs. It is good when you need both strength and flexibility.

| Type of Insulation Paper | Key Features | Common Uses |

| Electrical Grade | High dielectric strength, durable | Transformers, cables |

| Crepe Paper | Flexible, tear-resistant | Tight coil wrapping |

Pick electrical grade kraft paper for safe insulation in high-voltage or tough electrical work.

Laminated and Coated Kraft Paper

Some insulation paper needs extra protection in rough places. Laminated and coated kraft papers give more strength. Laminated aramid paper mixes aramid fibers, resin, and paper. This mix gives high strength, heat resistance, and good electrical insulation. Laminated Nomex uses layers of Nomex and other materials. It is flame resistant and very strong.

Coated kraft paper is also helpful. The coating protects against water, oil, and damage. This helps the paper keep its dielectric strength and stay stable in heat. Lamination and coating add layers that guard against heat, scratches, and stress from the environment.

If you need insulation that can handle heat, water, and stress, laminated or coated insulation paper is a good pick.

Kraft Paper vs. Alternatives

Fiberglass

Fiberglass is a popular choice for insulation. It keeps heat in during winter and out in summer. Its R-value is usually between R3 and R4 per inch. Loose-fill fiberglass can have even higher R-values, like R22 to R37.7, if you use more of it. You can buy fiberglass as batts, rolls, or loose pieces. People put it in walls, attics, and floors. Kraft paper does not make the R-value higher. It is used as a vapor retarder when stuck to fiberglass batts. If you want the best thermal insulation, pick fiberglass. Kraft paper is better as a helper, not the main insulator.

Plastic Films

Plastic films, such as polyethylene, are used in insulation jobs. They work as vapor barriers. These films are light and easy to use. Clear polyethylene is cheap and simple to put in. Black polyethylene can handle sunlight and is good for outside. Some films are cross-laminated or fiber-reinforced. These are stronger and last longer. The table below shows how plastic films and kraft paper compare as insulation facings:

| Material Type | Advantages | Disadvantages |

| Plastic Films | Cheap, easy to use, good vapor barrier, light, flexible, some are strong | Can tear, break down in sunlight unless treated, fragile, special films cost more |

| Kraft Paper (as substrate) | Good base for reflective layers, helps reflect heat, light, easy to use | Not a vapor barrier alone, not as tough as plastic films, needs other materials for full insulation |

Tip: Pick plastic films if you need a strong vapor barrier, but know they can rip or get weak in the sun.

Other Paper Insulation

There are other types of paper insulation too. Kraft paper is strong and trusted. It has high mechanical and dielectric strength, so it is good for electrical work. All paper insulation can wear out, especially if it gets hot or wet. Kraft paper lasts longer than most other paper insulations. Some types, like Nomex or Diamond Dotted Paper, have extra features. They might resist scratches or have resin for more strength. These types cost more money. Kraft paper gives you a good mix of strength, usefulness, and price. You can use it for many insulation jobs, but always check for damage as it gets older.

Kraft paper is tough and hard to tear.

It is great for electrical insulation.

It costs less than other paper-based choices.

All paper insulation traps air and slows heat.

Kraft paper is a smart and reliable pick.

Practical Considerations

Durability

You want your insulation to last a long time. Some things can make it wear out faster:

Moisture can get through kraft paper. It only slows water, not stops it.

If you put the paper on the wrong side, water can build up. This can cause wet spots.

Gaps near the edges or outlets let water in. This can make mold grow.

The paper does not bend much. It is hard to fit around odd shapes.

If you add extra vapor barriers the wrong way, water can get stuck between layers.

Sometimes, the paper hides gaps. This makes it hard to see problems.

Tip: Always seal air leaks and put the paper in the right spot to stop these issues.

Safety

You should look for safety labels when picking insulation. For electrical jobs, kraft paper insulation often meets rules like FSC® and PEFC™ for safe forests. It may also have ISO 9001:2008 for quality, ISO 14001:2004 for the environment, and ISO 45001:2018 for health and safety. These show the product is safe and good for factories. For homes, there are no special safety tags. You should always follow your local building rules.

Installation

Putting in insulation the right way helps it work better. Here are some easy steps:

Put the paper facing the warm side in winter. This is usually inside the wall.

Cut the insulation to fit tight between joists and around pipes or wires. Do not smash it.

Seal all cracks and holes to stop air from leaking.

Keep the insulation dry. Use vapor barriers and make sure air can move.

Check the insulation often for wet spots or mold.

For hard places, you might want to hire a pro.

Always follow your local codes and safety rules.

Note: The way you face the vapor barrier matters a lot. If you face it the wrong way, water can build up.

Environmental Impact

You might pick kraft paper insulation because it is green. But you should know all the facts. Kraft paper sometimes has asphalt. This can be bad for health when made or thrown away. Fake insulation uses more energy and makes more pollution. Natural fiber types like cellulose or hemp are better for the earth. Some coatings, like wax or polymers, help kraft paper block water. But they may not be fully safe for nature. New ideas try to make coatings that keep kraft paper safe for the planet.

When you pick kraft paper insulation, you get many good things.

It is strong against electricity. It bends easily. It can handle heat in many jobs.

New ideas and green treatments make it work better for big machines and smart homes.

More people want safe, earth-friendly, and low-cost choices, so the market is getting bigger.

Kraft paper insulation is a smart pick for now. It also helps make the world cleaner in the future.

FAQ

What makes kraft paper good for insulation?

Kraft paper is made with tough fibers. It does not tear easily and can take heat. It helps stop electricity and moisture from passing through. Many people pick it because it is good for the earth and saves money.

Can you recycle kraft paper insulation?

Yes, you can recycle kraft paper insulation. Most places that recycle will take it. The paper should be clean and dry before you recycle it. If it has glue or a coating, ask your local recycling center first.

How do you install kraft paper insulation?

Put the paper so it faces the warm side of the wall. Cut it so it fits tightly between the wall studs. Staple the edges so it stays in place. Keep the insulation dry so it works well.

Is kraft paper insulation safe for homes?

Kraft paper insulation is safe if you put it in the right way. It does not let out bad chemicals. Always follow safety rules and building codes when you install it.

Does kraft paper insulation stop water?

Kraft paper slows water but does not block it all the way. For more protection, use a vapor barrier or coated kraft paper. Keep the insulation dry to stop mold from growing.