Ever wondered what kind of plastic disposable coffee lids are made of? You’re not alone. These small but essential parts of your daily coffee run are made from various plastics—each with its own strengths, weaknesses, and uses.

In this post, we’ll break down the most common plastics used in disposable coffee cup lids, including PS, PP, and PET. You’ll learn how to identify each lid type, why certain plastics are chosen, and what it means for your coffee experience. Let’s get into the details.

What Are Disposable Coffee Lids?

Disposable coffee lids are more than just simple plastic covers. They're designed to make drinking hot or cold drinks cleaner, safer, and easier—especially when we’re on the move. Whether it’s on your way to school or during a long commute, these lids do a lot more than most people think.

What Are Coffee Cup Lids Used For?

Spill prevention

Lids help stop liquid from sloshing out of the cup while you walk, drive, or hold it in one hand. A small hole controls flow and prevents messy accidents.

Heat retention

A lid keeps the coffee warm longer. It slows down the release of steam and shields the drink from cool air outside.

Aroma preservation

Some lid designs let steam escape near your nose, so you can still smell the coffee. Aroma affects how we taste drinks.

Drinking convenience while on the go

With a lid, you don’t need to remove it every time you take a sip. It’s much easier to drink without looking or stopping what you’re doing.

How Are Disposable Coffee Lids Typically Designed?

Common shapes: flat, dome, sip-through, straw hole

Flat lids: Great for hot drinks. Often have a small opening for sipping.

Dome lids: Arched shape allows room for whipped toppings or foam.

Sip-through lids: Feature a built-in mouthpiece for direct drinking.

Straw hole lids: Come with a cross-slit or open center for inserting a straw.

Fit with cup diameters (e.g., 80mm, 90mm)

Lids must match the cup size to stay in place. Common sizes are 80mm, 90mm, and sometimes 98mm for larger cups. A loose fit can lead to leaks or spills.

Lockable, tearable, or flip designs

Lockable lids: Have a tab you can push back and snap into place.

Tearable lids: Feature a thin cover you rip open at the sip hole.

Flip lids: Include a hinged flap you lift and press back down after drinking.

| Lid Style | Use Case | Common Plastic Used |

| Flat Lid | Hot drinks (e.g., coffee) | PS, PP |

| Dome Lid | Topped drinks | PET, PP |

| Straw Lid | Cold beverages | PET, PP |

| Sip-Through | Daily coffee, espresso | PS, PP |

Types of Plastic Used in Disposable Coffee Lids

1. Polystyrene (PS)

What Is Polystyrene?

Polystyrene, or PS, is a stiff, lightweight plastic often used in hot drink lids. It’s easy to mold and holds its shape well under normal use.

It feels hard when you press it.

Glass transition temp: 90°C–100°C

Melting point: around 210°C–249°C

Why Is It Used in Coffee Lids?

This plastic is affordable and simple to shape using molds, making it great for mass production.

PS lids are fully opaque, which hides the drink surface but provides a neat appearance.

You’ll often find PS lids on basic takeaway hot coffee cups.

Downsides of PS

While it holds its form, it can crack easily under sudden pressure or if dropped.

When heated beyond normal use, PS may release small amounts of styrene, a chemical some people try to avoid.

2. Polypropylene (PP)

What Is Polypropylene?

PP feels more flexible than PS and looks a bit cloudy. You can bend it slightly without it snapping, which makes it ideal for active use.

It comes in many colors—black, white, red, or even clear-ish.

Often used in straw lids and bubble tea cups.

Why Use PP for Coffee Cup Lids?

PP holds up well against heat. It can tolerate up to 120°C without melting or losing shape.

It resists tearing, moisture, and chemical damage, making it long-lasting during use.

Many lids with flip tops or straw holes are made from PP due to its flexibility and strength.

3. Polyethylene Terephthalate (PET)

What Is PET?

PET is clear and lightweight. It’s known for its excellent clarity—great for showing off colorful or layered drinks.

Applications in Disposable Lids

Characteristics Summary

| Property | PS Lids | PP Lids | PET Lids |

| Transparency | Opaque (0%) | Semi (20–50%) | Clear (80–100%) |

| Suitability | Hot/Cold Drinks | Hot/Cold Drinks | Cold Drinks Only |

| Flexibility | Rigid | Flexible | Moderate |

| Recyclability Code | #6 | #5 | #1 |

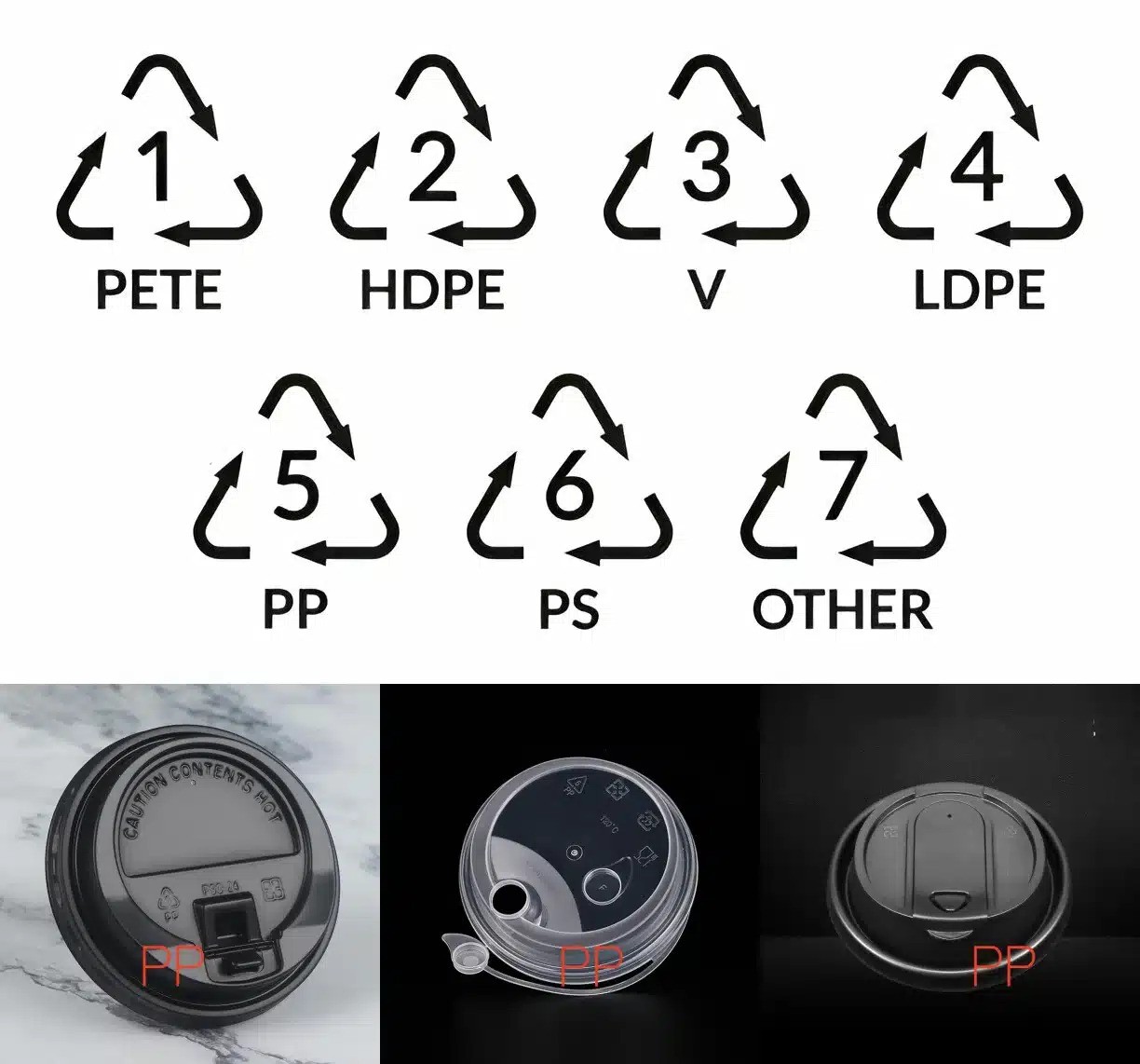

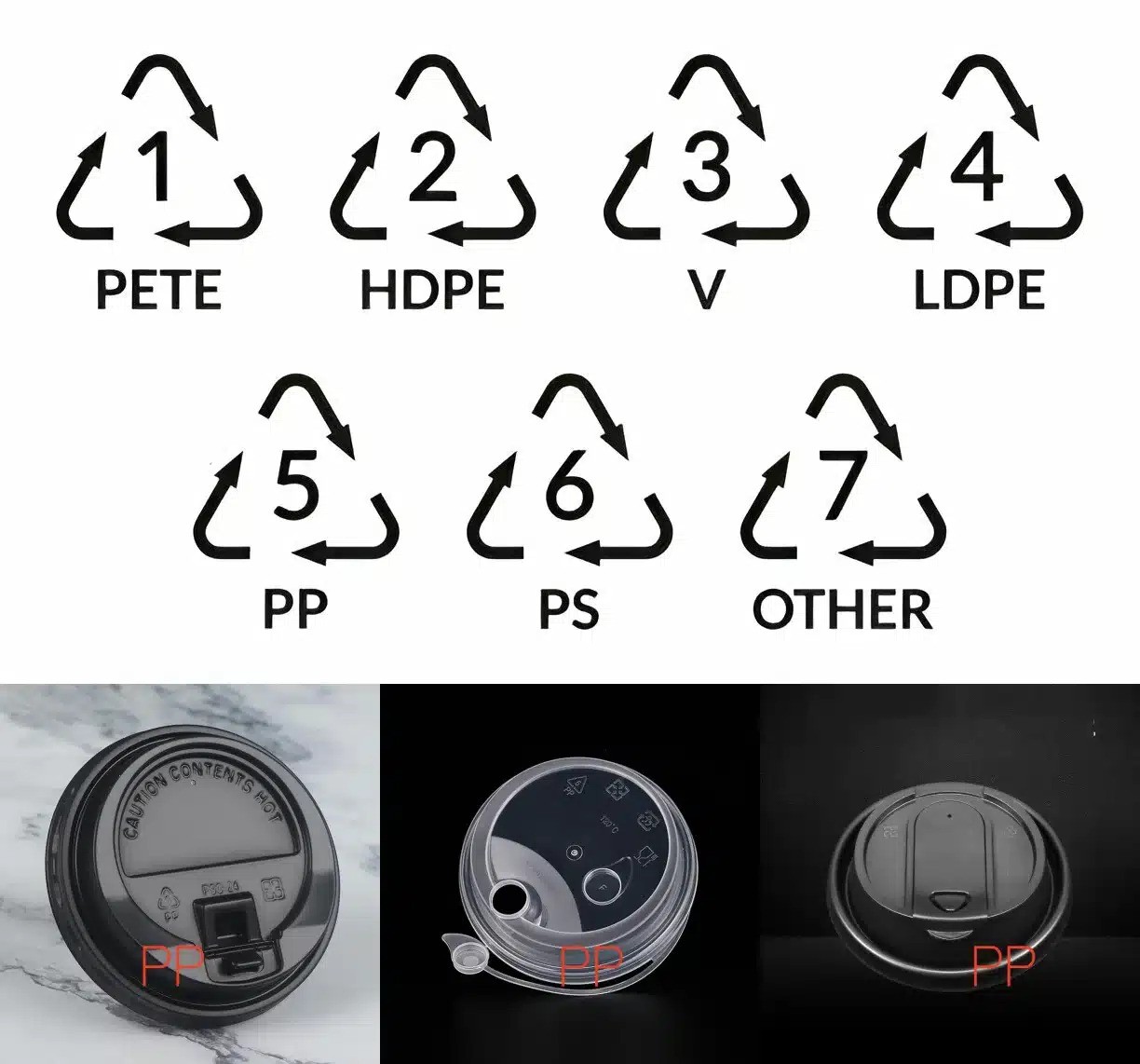

Identifying Lid Materials by Symbols

Recycling Symbols and What They Mean

Recycling symbols are molded into the plastic, usually on the underside of the lid. They include a number (inside a triangle) and sometimes a letter code. Here’s what each common symbol means:

#6 PS: Found on stiff, opaque lids. Often embossed near the edge of the lid face.

#5 PP: Appears on flexible, slightly cloudy lids with tab or straw openings.

#1 PET: Seen on crystal-clear lids, usually on dome or cold drink styles.

#7 Other: Used for alternative plastics like PLA; check for “PLA” label near the number.

How to Tell Which Plastic a Lid Is Made Of

Recycling number

Visual differences (color, clarity, texture)

PS is totally opaque and smooth, often in black or white.

PP has a soft shine and slight cloudiness; can come in more colors.

PET is crystal clear and glass-like—used to show off drinks.

Touch and flexibility clues

PS feels rigid and snaps under pressure.

PP bends a little before breaking and has a smoother edge.

PET is light but firm; it doesn’t flex as much as PP.

Are All Clear Lids Made of PET?

It’s easy to assume a clear coffee lid must be made of PET—but that’s not always true. While PET is the most common clear plastic for cold drinks, some PS and PP lids also come in clear versions. They may look alike, but they don’t behave the same way.

Clarify Common Misconception

Many people think all transparent lids are PET just because they’re clear. That’s not accurate. Some manufacturers produce crystal-clear PS lids for hot drinks. You might even see slightly translucent PP lids that appear nearly clear but offer more flexibility. We can’t rely on looks alone to judge the material.

Comparison of Clear PS, Clear PP, and PET

| Feature | Clear PS Lids | Clear PP Lids | PET Lids |

| Clarity (%) | 50–70% (semi-clear) | 60–80% (slightly cloudy) | 80–100% (high clarity) |

| Flexibility | Low (brittle feel) | Medium (bends slightly) | Moderate (sturdy but rigid) |

| Heat Resistance | Moderate (for hot drinks) | High (can handle heat) | Low (used for cold drinks) |

| Feel | Hard, crisp edges | Softer, smooth to the touch | Light, firm, glass-like |

| Recyclability Code | #6 | #5 | #1 |

How to Differentiate Between Them

By appearance

PS may look clear but has a slight haze when held to light.

PP appears slightly duller or cloudy, especially around the rim.

PET is the clearest, often completely transparent like glass.

By flexibility

Gently press the lid. If it cracks or feels stiff, it’s likely PS.

If it flexes a bit without snapping, it could be PP.

PET bends less than PP, but doesn’t break like PS.

By recycling code

Check for the small triangle underneath the lid.

#6 = PS, #5 = PP, #1 = PET. These codes help confirm the actual material.

Common Sizes and Compatibility

Lid Sizes by Cup Diameter

Lid sizes are measured by diameter in millimeters. Each lid is made to snap securely onto a cup rim that matches the size exactly. If it’s too loose or tight, the lid won’t stay on properly.

| Lid Diameter | Common Cup Size | Usage Type |

| 62mm | 4 oz | Espresso or sample cups |

| 72mm | 6 oz | Small cappuccino cups |

| 80mm | 8 oz | Short coffee or tea |

| 90mm | 12–16 oz | Standard coffee drinks |

| 98mm | 16–20 oz | Large iced beverages |

| 107mm | 24 oz | Oversized cold drinks |

80mm and 90mm lids are the most commonly used in daily coffee service.

Cold drink cups—especially with dome lids—tend to use 98mm or 107mm diameters.

Matching cup and lid size ensures safe handling, especially for hot drinks.

Type of Cups That Match Each Lid Material

Lid and cup materials are usually paired to match in texture and performance. This keeps the lid in place and avoids warping, cracking, or leaking during use.

Paper Cups

Typically used with PS or PP lids.

These cups have rolled rims that need firm but flexible lids.

PS lids work well for hot drinks, while PP is better when more flex is needed.

PET Cups

Always matched with PET lids.

PET cups are crystal-clear and mainly for cold drinks like iced tea or smoothies.

Dome lids and flat straw lids made from PET fit best.

PP Cups

Typically paired with PP lids.

PP-to-PP combinations offer a consistent seal and visual match.

Popular in bubble tea shops where injection-molded cups are standard.

| Cup Type | Typical Lid Material | Common Drink Type |

| Paper Cup | PS, PP | Hot coffee, tea |

| PET Cup | PET | Iced coffee, smoothies |

| PP Cup | PP | Milk tea, cold drinks |

Special Lid Designs Using These Plastics

Flat Lids

Flat lids are commonly used for hot drinks like black coffee or Americanos. They’re low-profile and often have a narrow sip hole near the edge. These lids are usually made from PS or PP, depending on the flexibility needed.

PS flat lids feel more rigid and are better for short trips.

PP flat lids have a slightly softer touch and work better if you need to press-fit them frequently.

Some flat lids have a small tab that opens and closes the sip hole, helping prevent leaks.

Dome Lids

Dome lids are curved or bubble-shaped. You’ll see them often on drinks with whipped cream, foam, or other toppings that rise above the rim. These are made from PET because it's clear and sturdy, perfect for showcasing the drink.

PET’s clarity lets the drink and topping stay visible.

The arched shape gives extra room above the cup without spilling.

Dome lids may have a central straw hole or just a small vent.

Straw Lids and Sip-Through Lids

These lids let you drink without removing the cover. They’re super handy for on-the-go use, especially when you’re walking or driving. Both PP and PS are used depending on the flexibility and locking feature needed.

Pop-open lids

Tearable lids

| Design Type | Features | Plastic Material |

| Pop-Open Lid | Flip tab, sip or straw option | PP or PS |

| Tearable Lid | Thin, peel-back seal over sip hole | PS |

| Sip-Through | Pre-cut opening, no cover needed | PP or PS |

How Are Plastic Coffee Cup Lids Made?

Basic Manufacturing Process

Injection molding for PP and PS

Injection molding is the primary method for producing coffee cup lids from polypropylene (PP) and polystyrene (PS). Resin pellets are heated until they melt, then injected into molds. Once cooled, the plastic takes shape.

Thermoforming for PET

For polyethylene terephthalate (PET) lids, manufacturers use thermoforming. A plastic sheet is heated until soft and then pressed into molds. This method allows for quick production of thin lids with detailed designs.

Use of resin pellets, heat, and mold shaping

Both methods rely on resin pellets, heat, and precise molding. This ensures consistency in lid size and strength.

Quality Control Factors

Thickness and sealing

The thickness of the plastic ensures durability. Lids must be sealed properly to avoid leaks, requiring careful temperature control.

Tolerance and cup fit

Accuracy in mold dimensions guarantees lids fit securely on cups. Even small variations can lead to loose or ill-fitting lids.

Are There Safety Concerns With Coffee Lid Plastics?

Heat Exposure and Chemical Leaching

What happens to PS and PP under heat

When exposed to high temperatures, polystyrene (PS) and polypropylene (PP) can soften or degrade. This can lead to the release of small amounts of chemicals, especially when the lid is used for hot drinks.

Known issues with styrene (PS)

Styrene, a compound in PS, has been linked to potential health risks when heated. Though research on this is ongoing, styrene exposure is a concern in food-grade materials.

Regulatory standards on food contact plastics

There are strict regulations in place to ensure plastics used in food contact items, including coffee lids, are safe. Materials must meet guidelines set by agencies like the FDA and European Food Safety Authority.

Taste and Scent Impact

How lids may affect flavor

The material of coffee lids, particularly PS, can sometimes alter the flavor of hot beverages. This change happens due to chemical interactions between the plastic and the drink.

Design features that enhance aroma flow

Lids are often designed with small vents or features to help improve the flow of aroma. This not only helps with taste perception but also provides a more enjoyable coffee experience.

Conclusion

Disposable coffee lids are typically made from polystyrene (PS), polypropylene (PP), and polyethylene terephthalate (PET). Each material offers unique properties, such as PS's opacity, PP's flexibility and heat resistance, and PET's transparency. Understanding these materials helps consumers choose suitable lids.

Material knowledge is essential for consumers and businesses to ensure proper functionality, safety, and environmental impact. By recognizing lid types, we can make informed decisions on recycling and disposal, promoting sustainability in daily coffee consumption.

FAQ

Q1: Are all disposable coffee lids made from plastic?

No, but most lids are made from plastics like PS, PP, or PET.

Q2: Is PS plastic safe for hot drinks?

PS plastic can release chemicals when exposed to high heat, raising some safety concerns.

Q3: How can I tell if a lid is recyclable?

Check for recycling symbols, typically found on the lid, to know if it’s recyclable.

Q4: Which plastic lid is most durable?

PP lids are generally the most durable, offering strength and heat resistance.